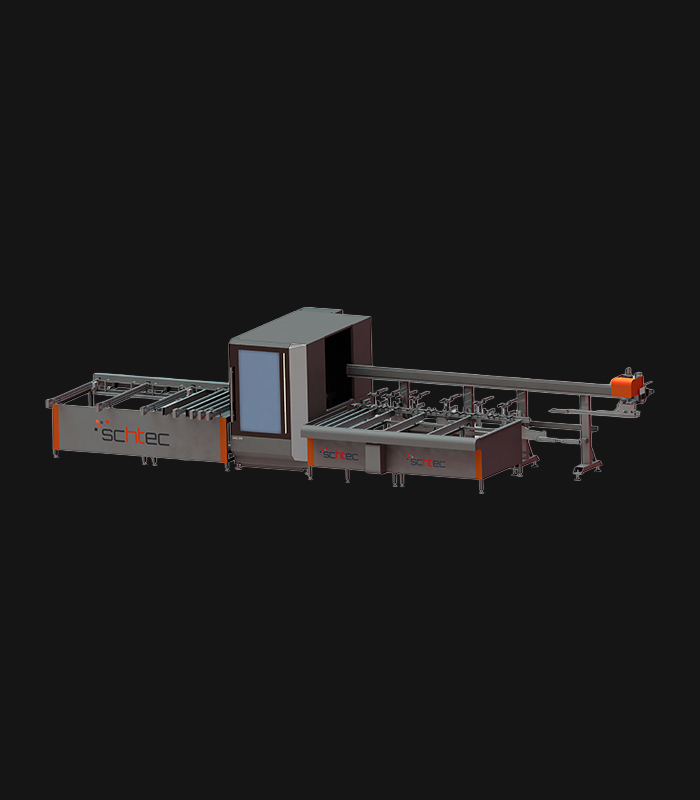

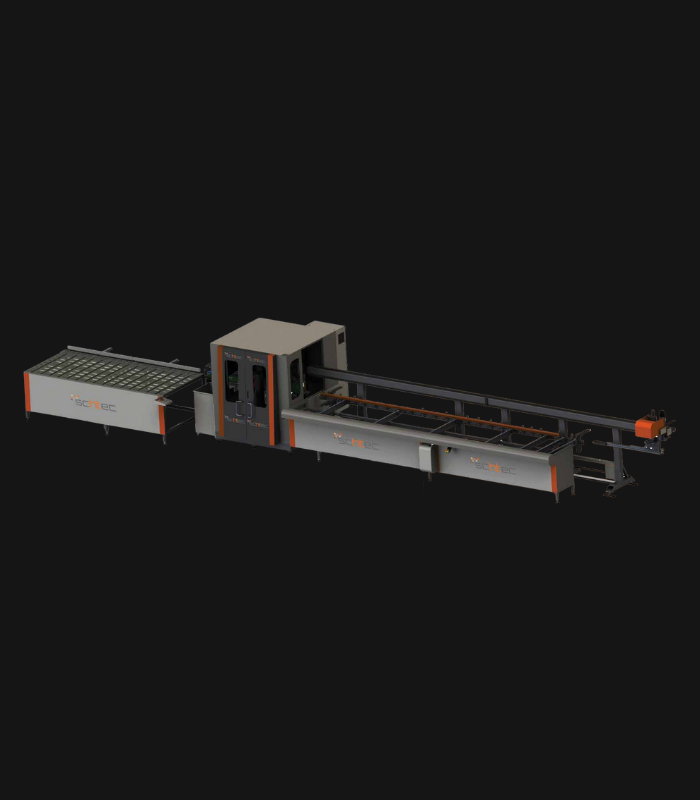

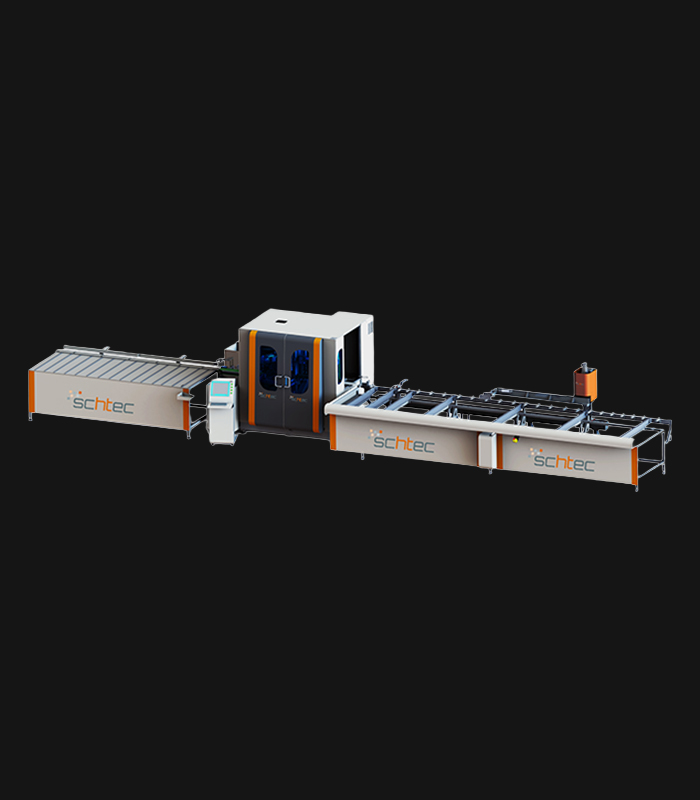

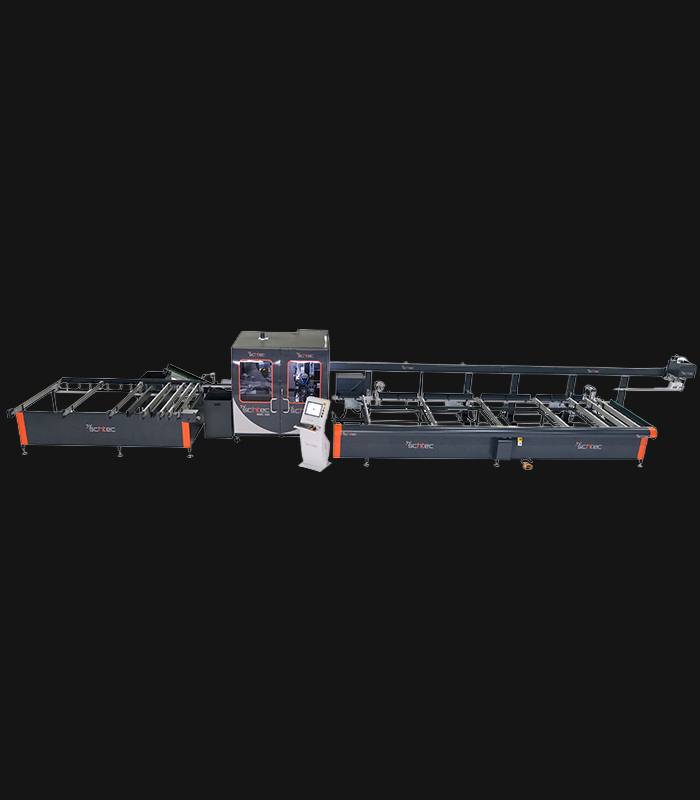

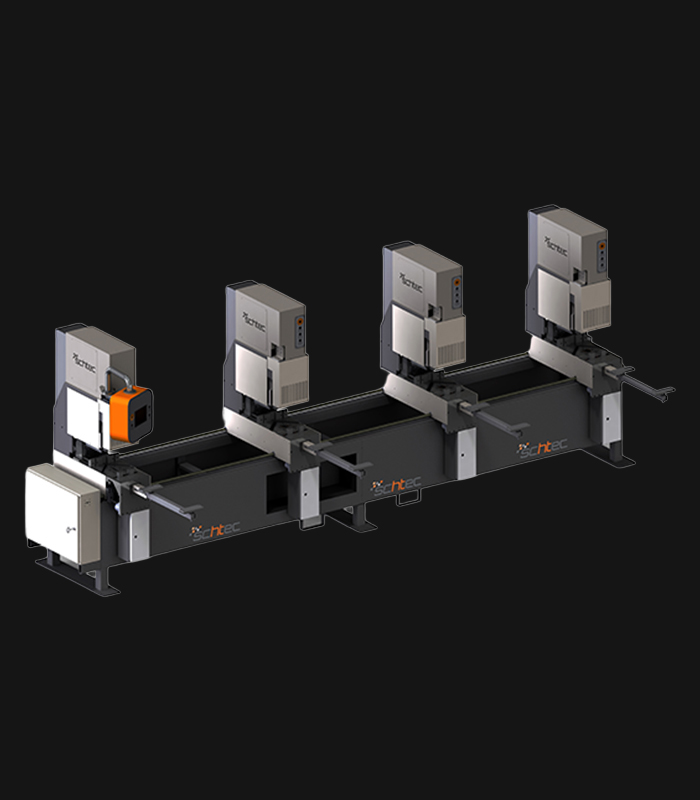

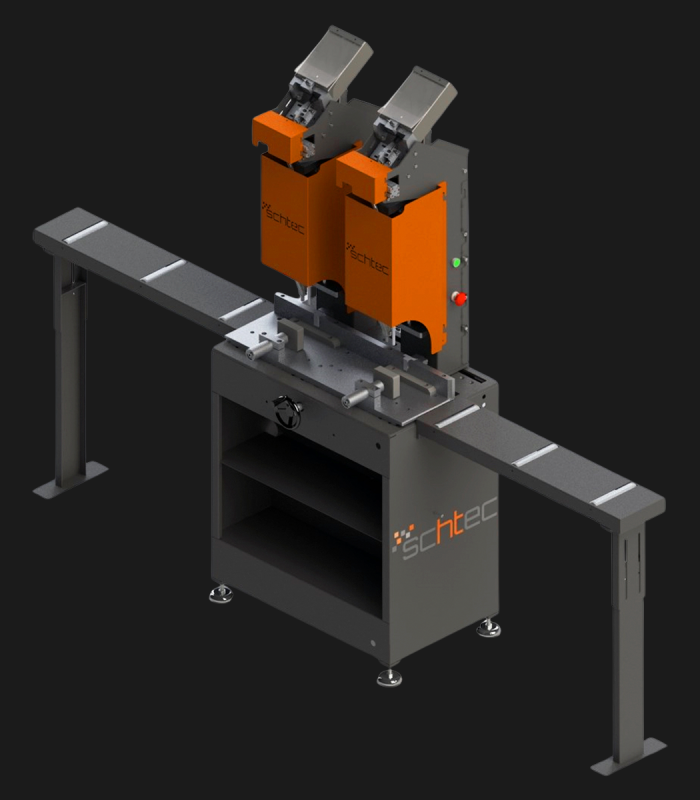

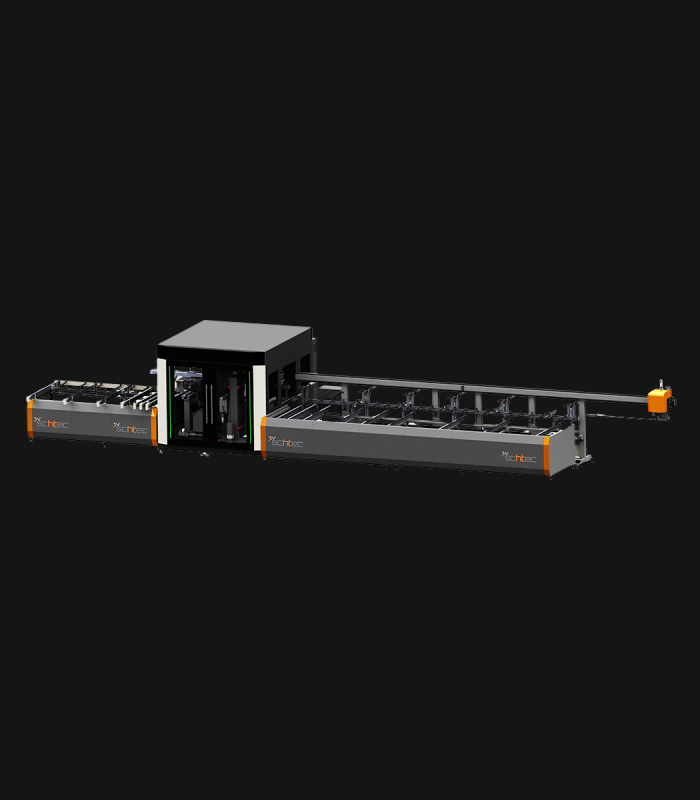

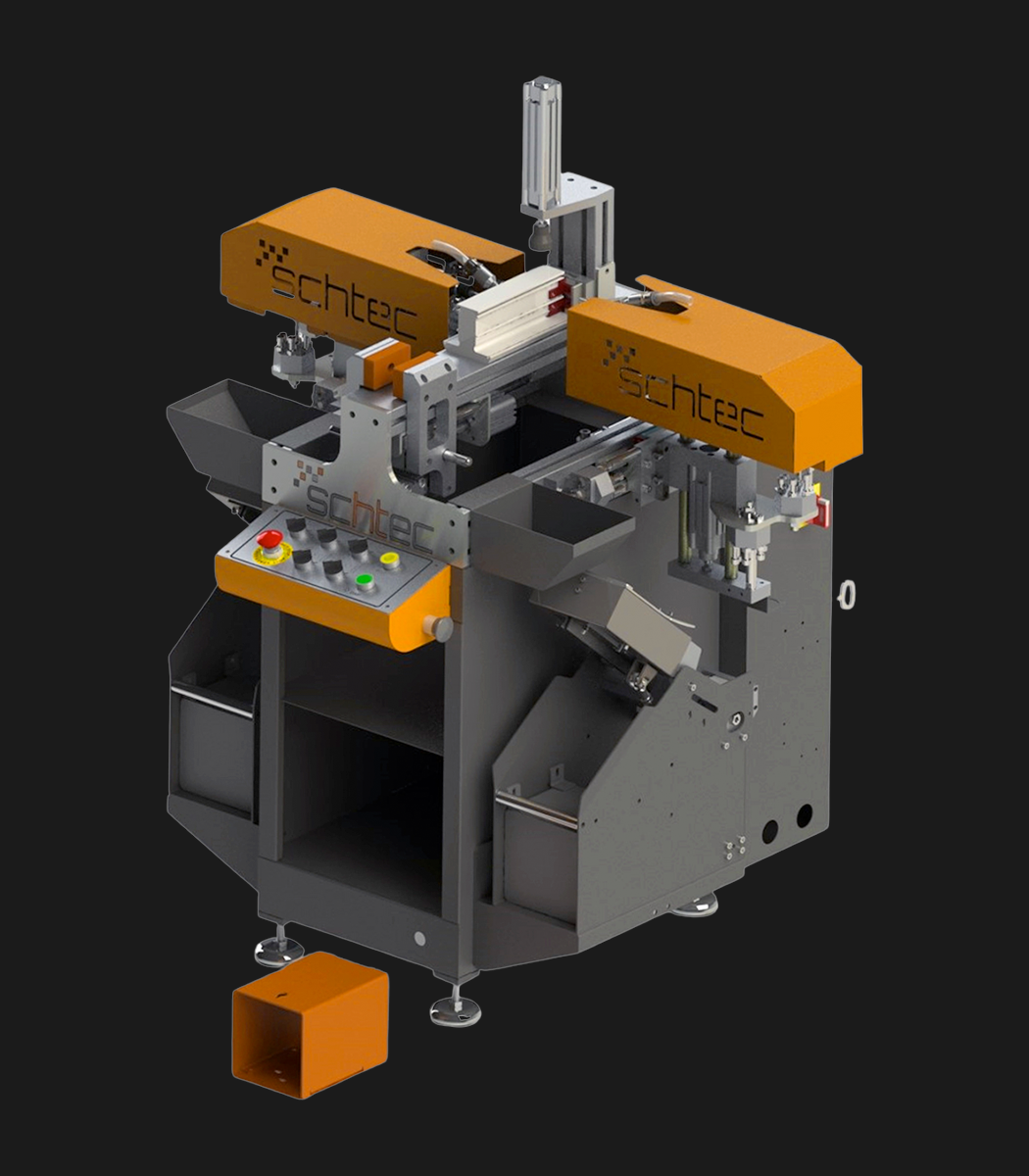

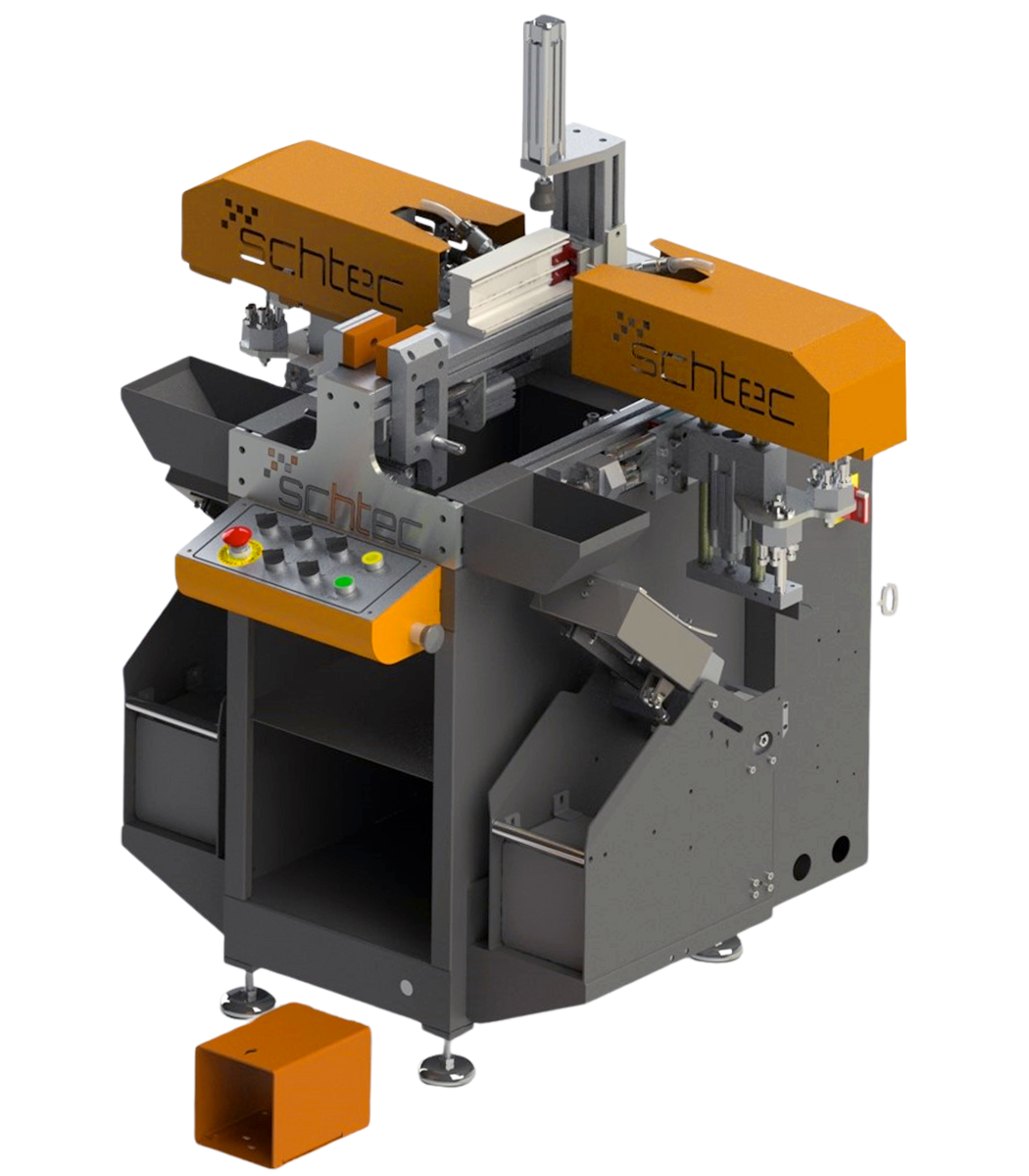

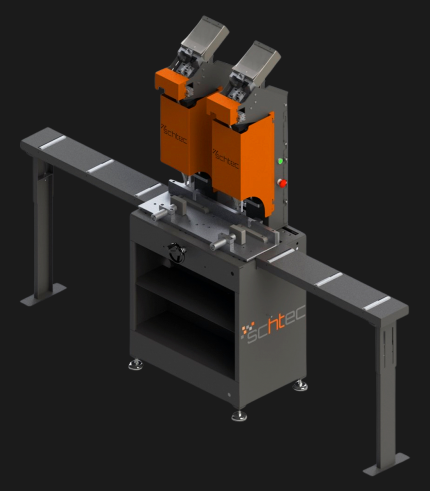

RT 176 Automatic Mullion Connector Screwing Machine

Schtec RT 176 screws PVC mullion blocks with dual-sided precision in 5.5 sec. Supports 4 series with easy adjustments for fast, error-free production.

RT 176 Technical Specifications

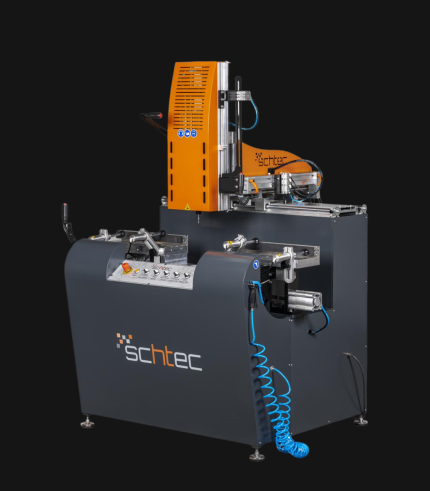

| Air Pressure | 6-8 bar |

| Air Consumption | 75 lt./min. |

| Machine Height | 1.560 mm |

| Machine Length | 1.550 mm |

| Machine Width | 915 mm |

| Machine Weight | 185 kg |

Standard Features

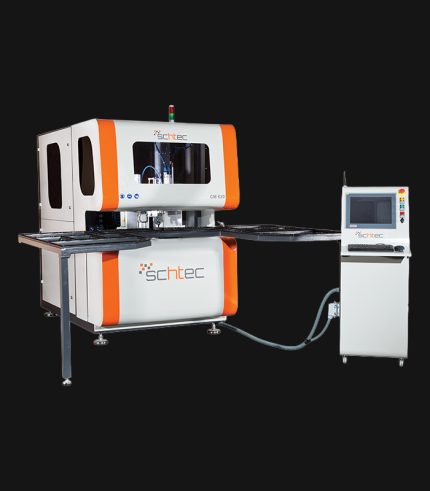

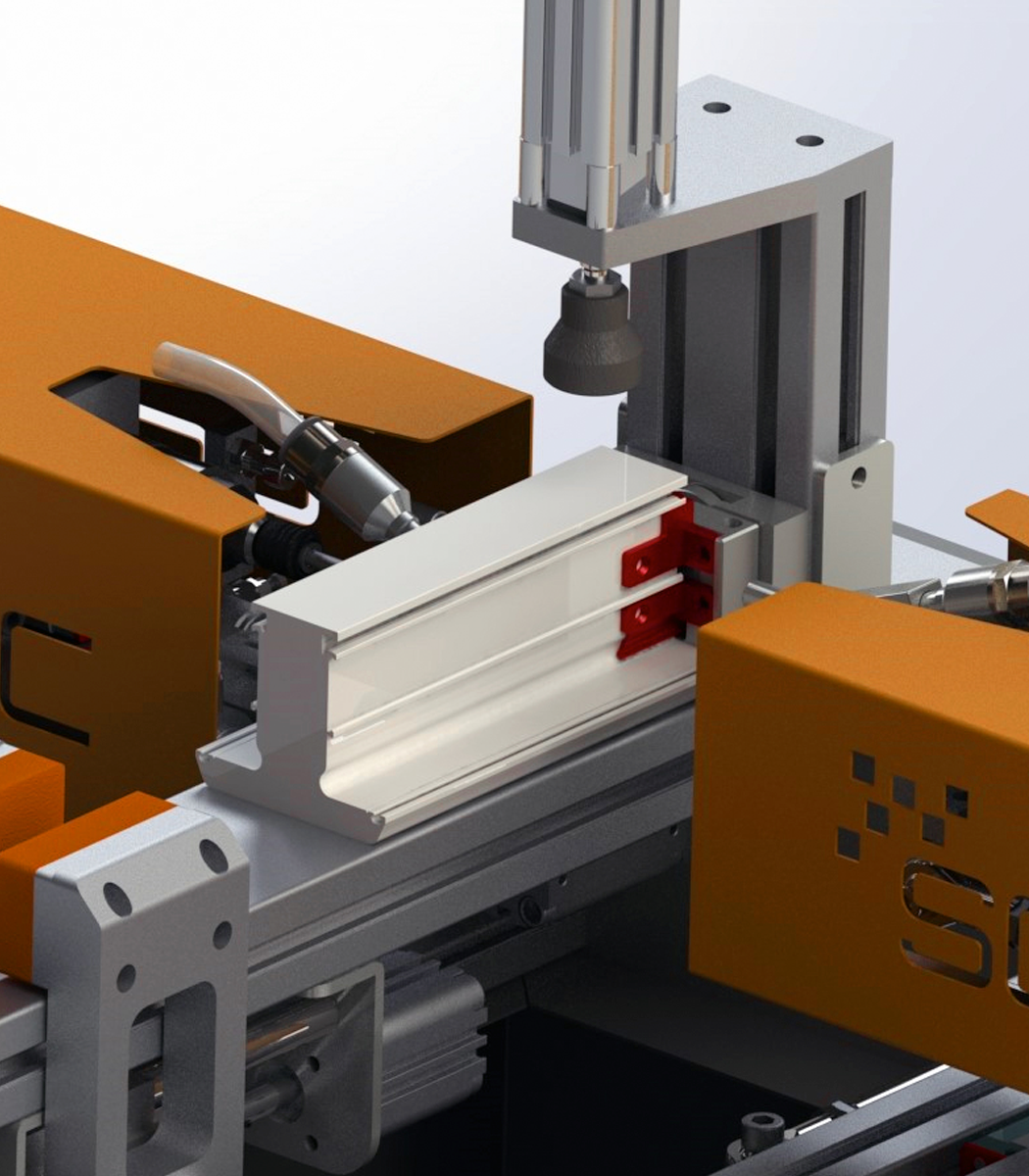

- Automatic screwing of mullion connectors used on different series and sizes of PVC mullion profiles in one time from both sides positioning with settings

- Possibility to use 4 types of connector in the same time without change settings

- Automatic screwing with double side automatic screw feeding unit

- Automatic clamp and profile centering system

- Possibility for easy setting and position change

- Connector joining speed 5.5 sec./pc.

Product Description

The Schtec RT 176 is a high-efficiency machine that automatically screws connecting blocks into PVC mullion profiles. Capable of working with four different series at once, it screws from both sides simultaneously, enhancing production speed. It delivers error-free performance with dual-sided automatic screw feeding, pressing, and centering mechanisms. The block mounting is completed in approximately 5.5 seconds. Its user-friendly design allows easy position adjustments and quick series transitions. The RT 176 delivers speed, efficiency, and consistency for mullion block installation in PVC window systems.

Frequently Asked Questions

Find quick answers to common questions about our Screwing & Reinforcement Machines.