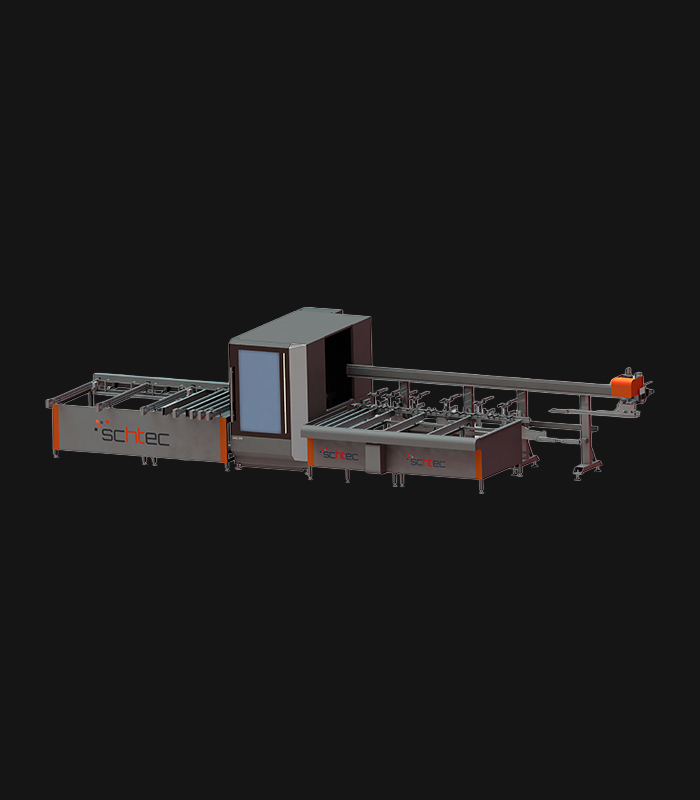

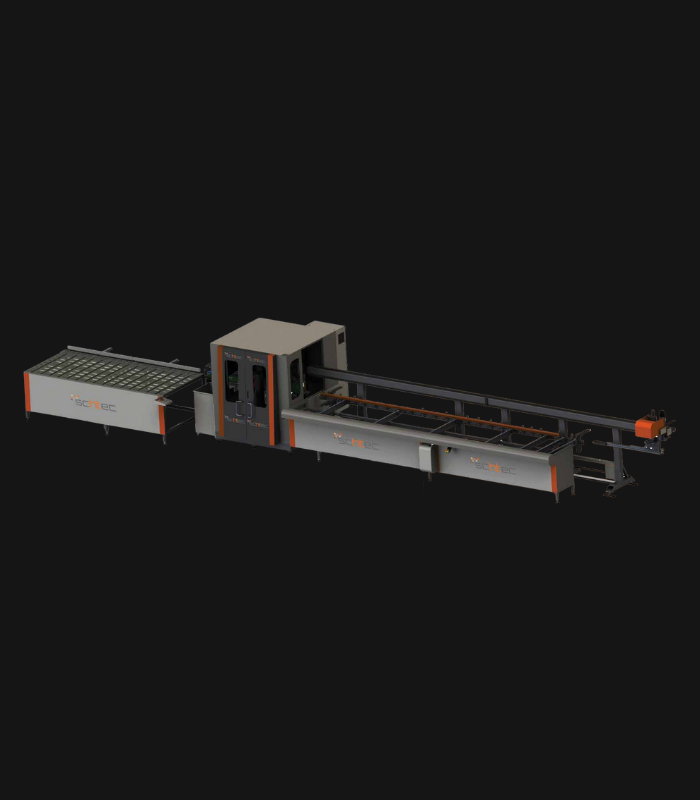

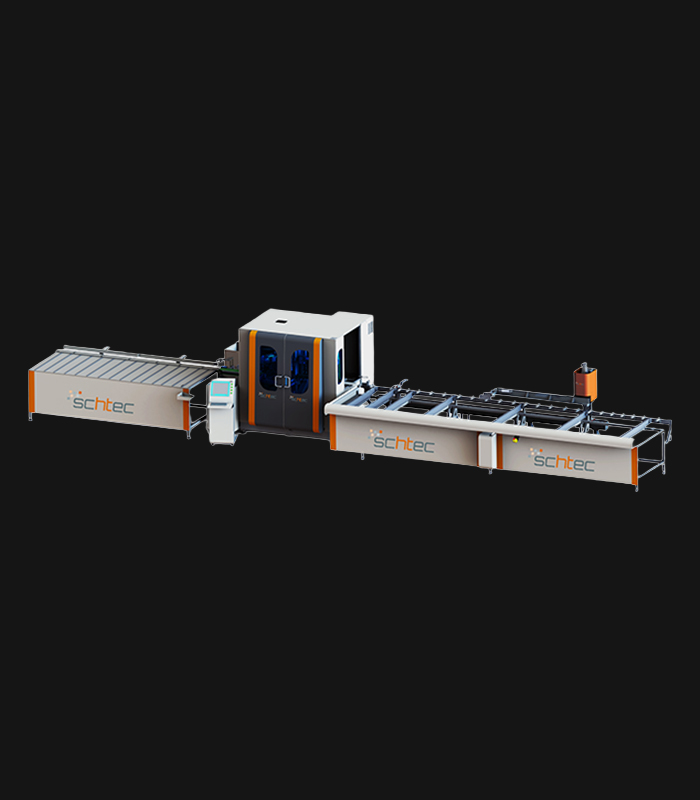

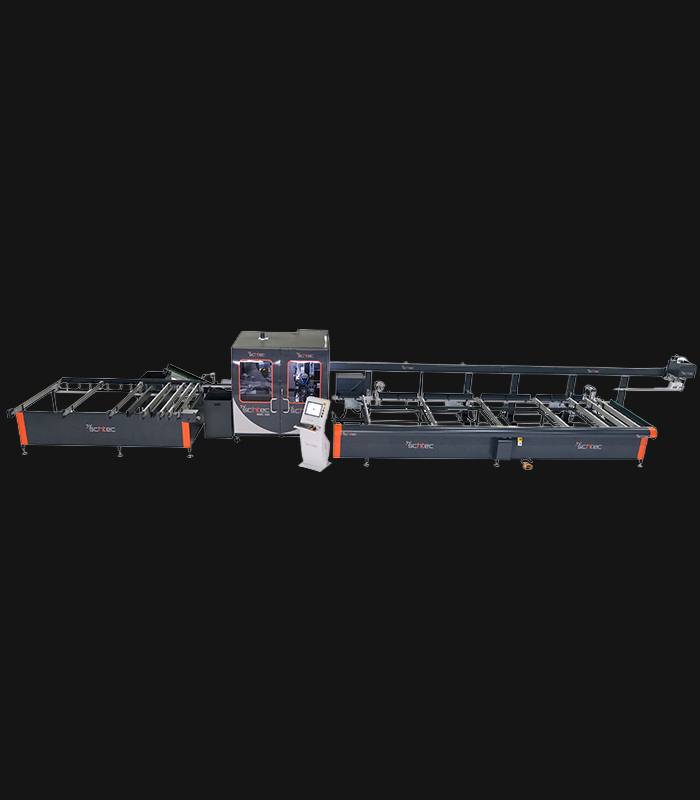

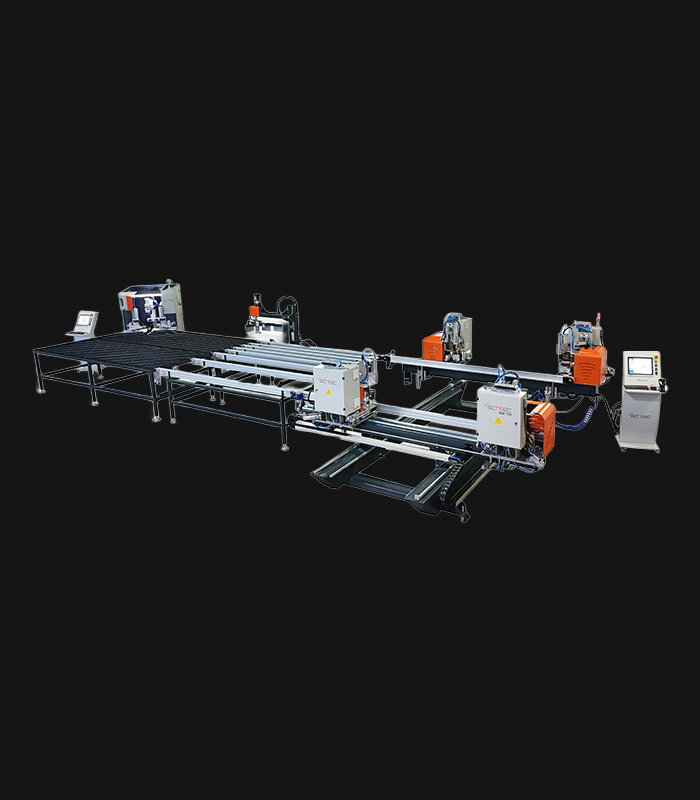

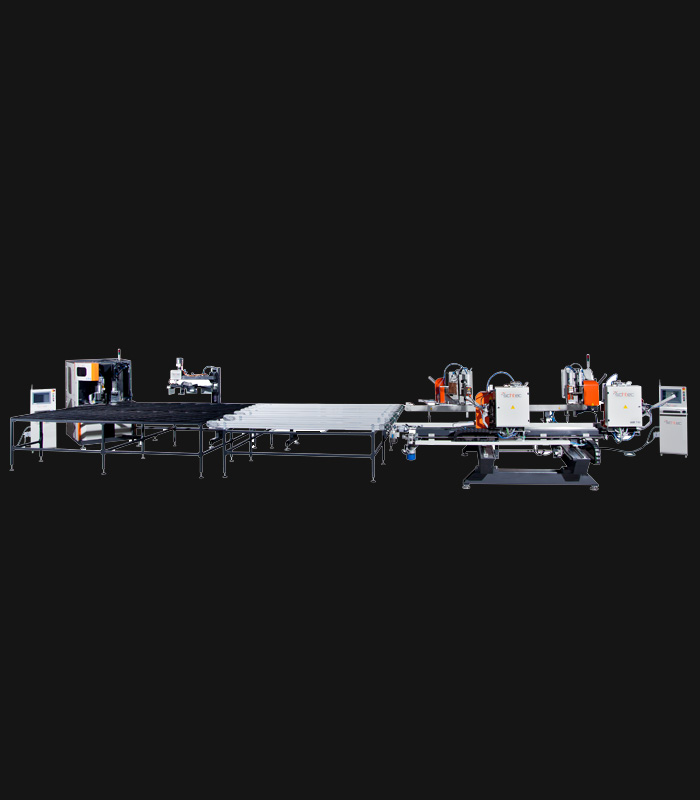

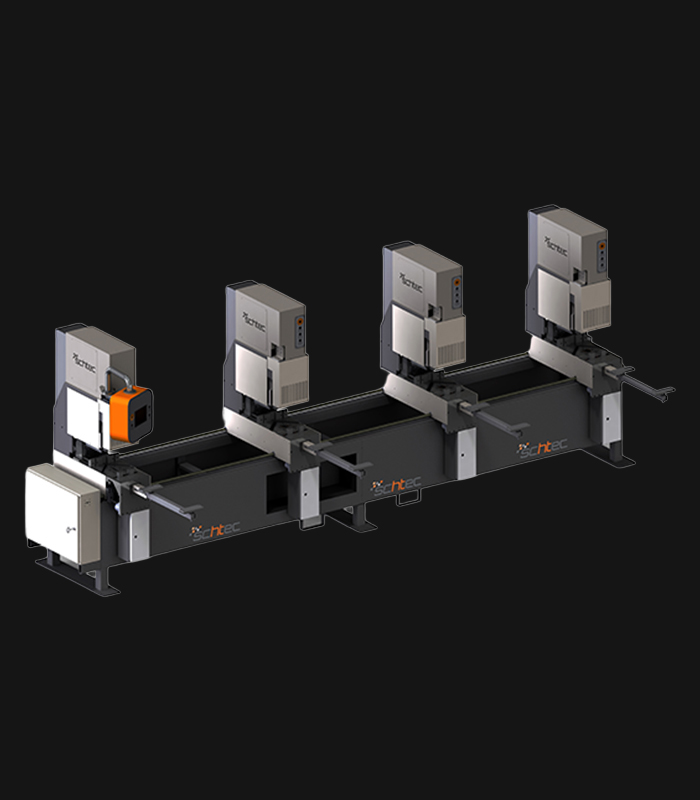

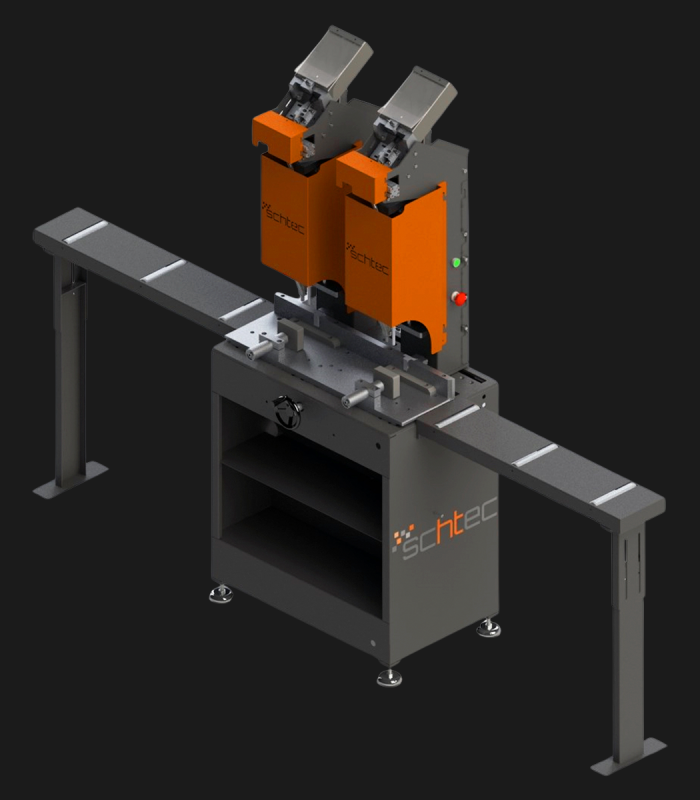

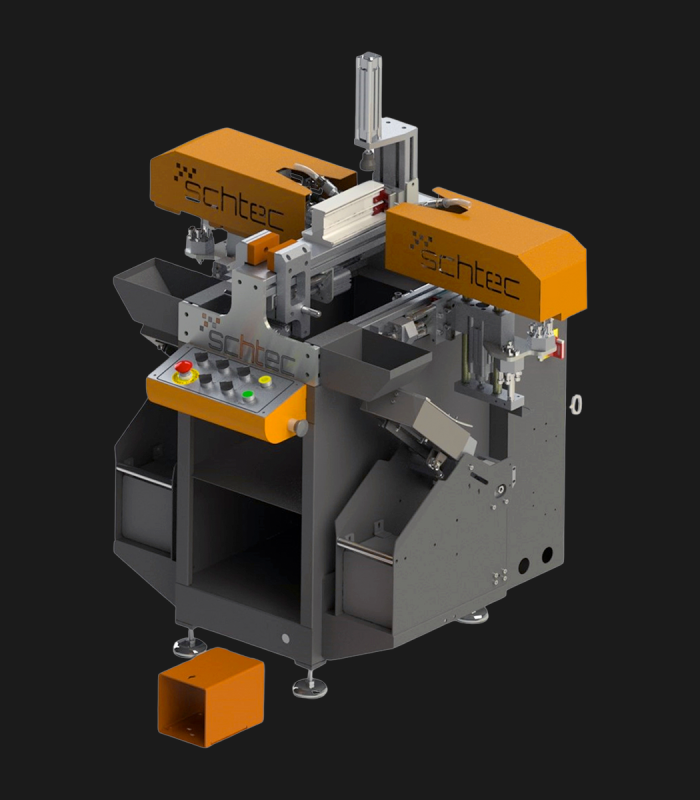

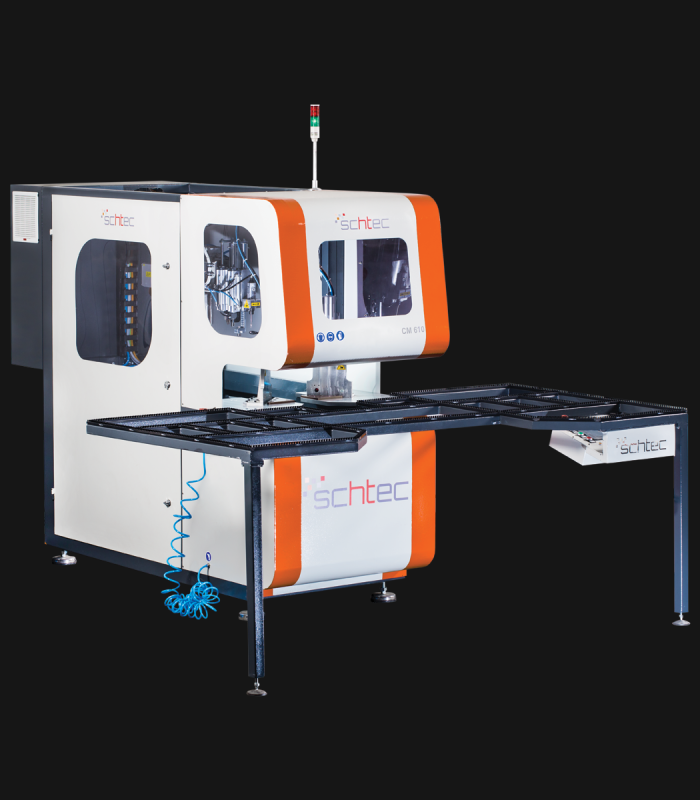

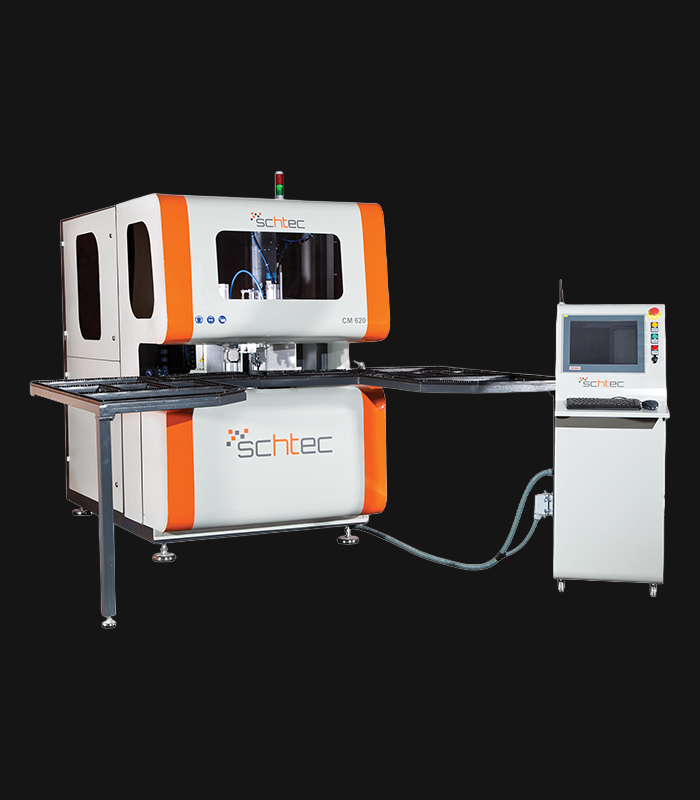

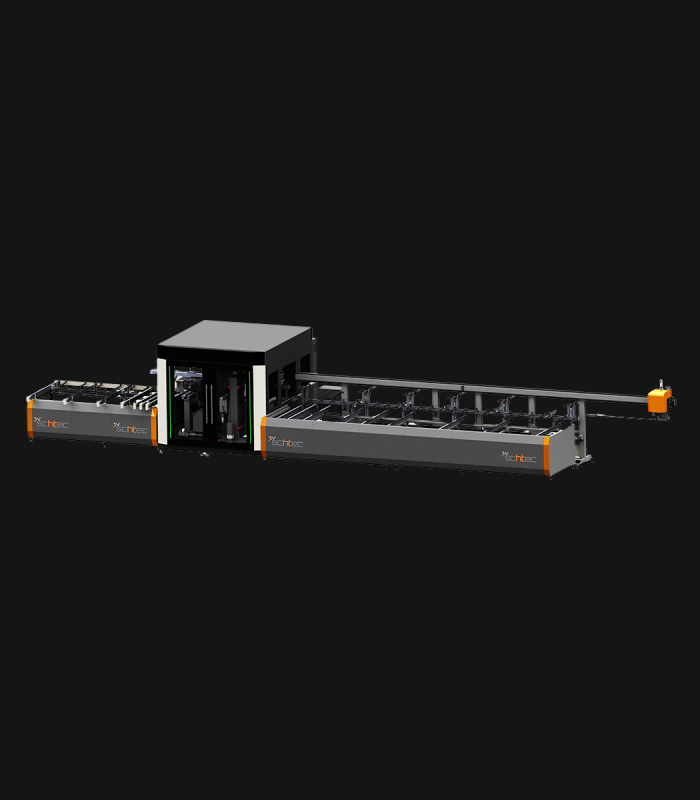

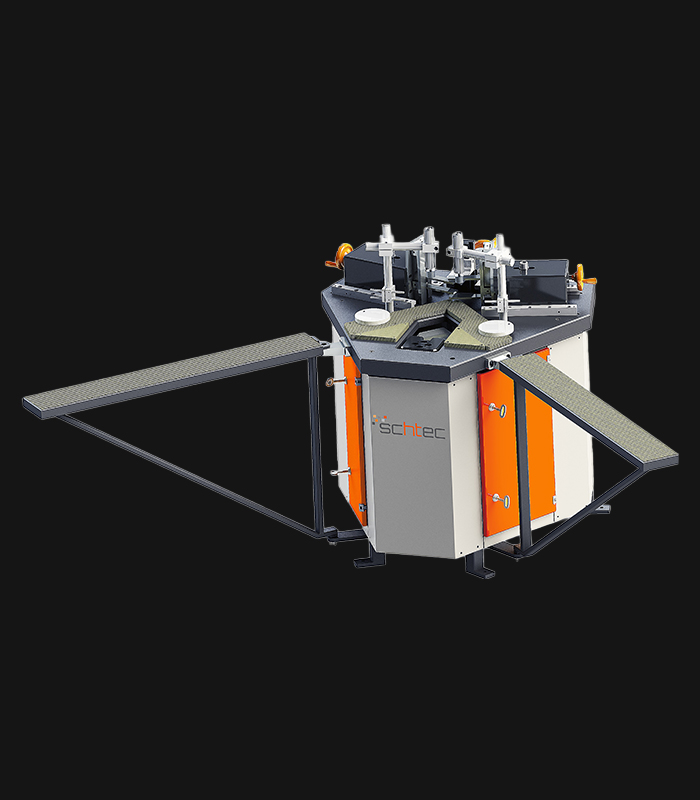

MT 252 Automatic Multiple End Milling Machine

The SCHTEC MT 252 automatically performs high-precision end milling on PVC mullions with an easy-change single-blade system, adjustable feed speed, and pneumatic clamping for fast, stable, and efficient production.

MT 252 Technical Specifications

| Power Supply | 400 V, 3 Ph, 50-60 Hz |

| Motor Power | 1.1 kW |

| Motor Speed | 3,000 rpm |

| Air Pressure | 6-8 bar |

| Air Consumption | 20 lt./min |

| Max. Saw Diameter | Ø160 mm |

| Max. Notching Height | 90 mm |

| Max. Notching Depth | 30 mm |

| Max. Profile Width | 120 mm |

| Max. Profile Height | 90 mm |

| Machine Width | 860 mm |

| Machine Height | 1,240 mm |

| Machine Length | 1,070 mm |

| Machine Weight | 125 kg |

Standard Features

- Performs mullion end milling of PVC profiles with high quality and precision

- Performs the milling process automatically

- Operates with an easy-to-change single-blade cutter system

- Allows processing of different profile types without adjustment or time loss

- Profiles are fixed vertically and horizontally with pneumatic pistons

- The blade feed speed is adjustable

- Allows processing at different angles up to 45°

Optional Features

- Cooling system and hydro-pneumatic system for aluminium profiles

Product Description

The SCHTEC MT 252 Automatic Single End Milling Machine delivers high precision and efficiency in milling PVC mullion ends. Equipped with an easy-to-change single-blade cutter system, it automatically performs accurate milling operations without the need for manual adjustments. Profiles are clamped vertically and horizontally with pneumatic pistons, ensuring maximum stability during processing. The adjustable blade feed speed and the ability to mill at angles up to 45° make it a versatile solution for different profile types. Designed for both performance and practicality, the MT 252 provides consistent, high-quality results and minimizes setup time, making it ideal for modern PVC production lines.

Frequently Asked Questions

Find quick answers to common questions about our End Milling Machines for PVC Profiles.