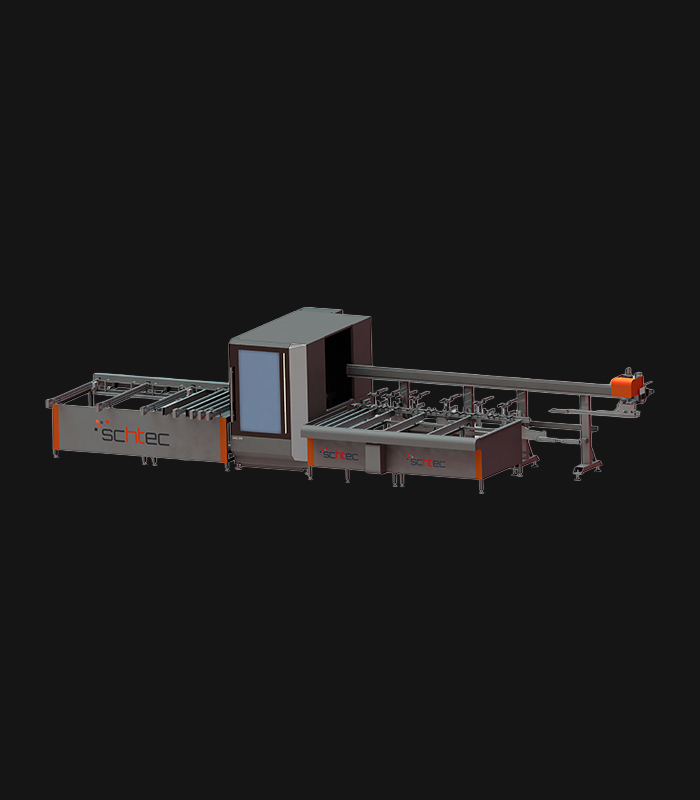

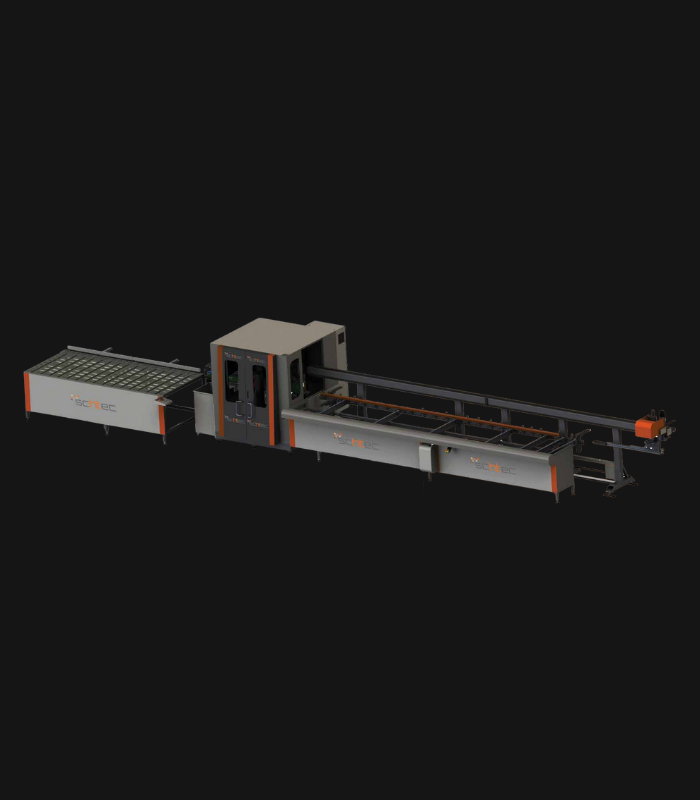

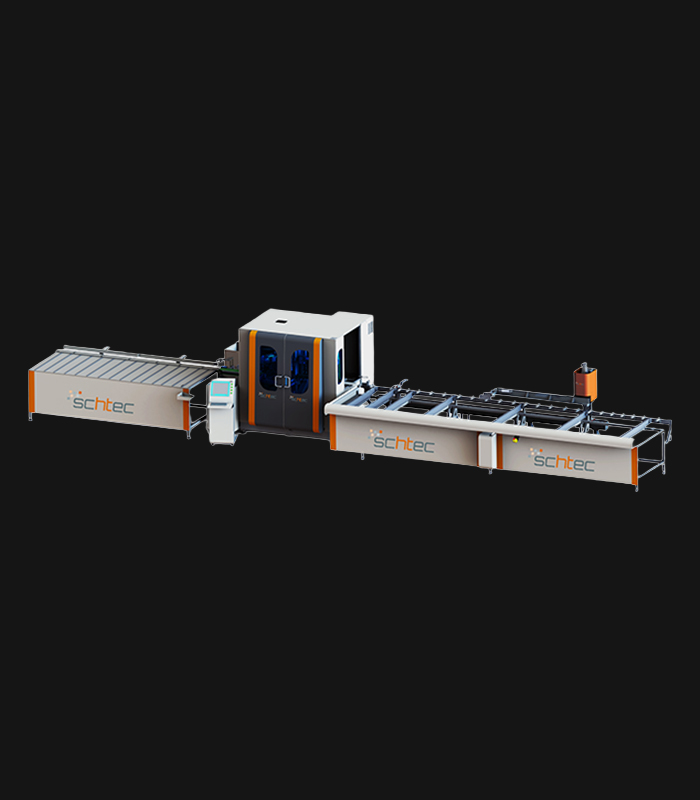

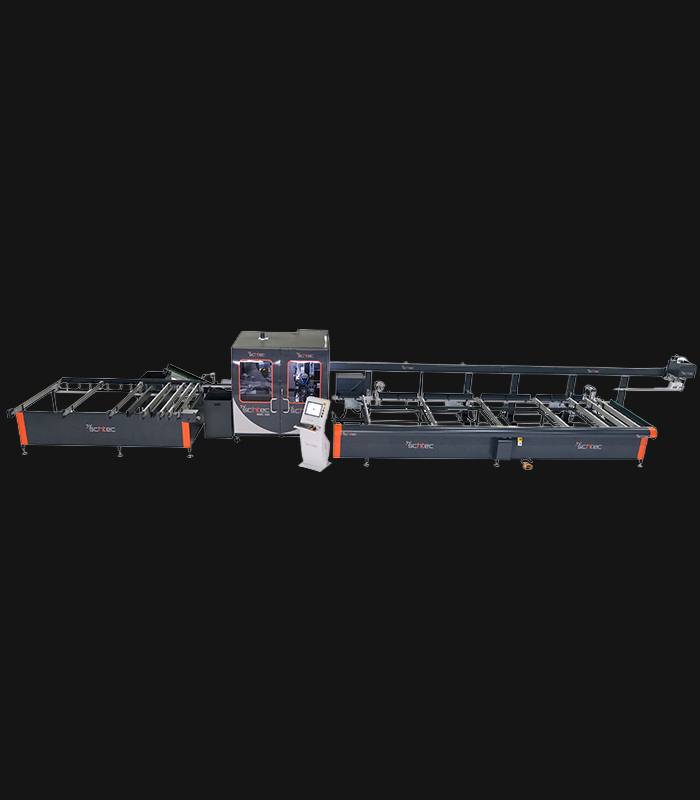

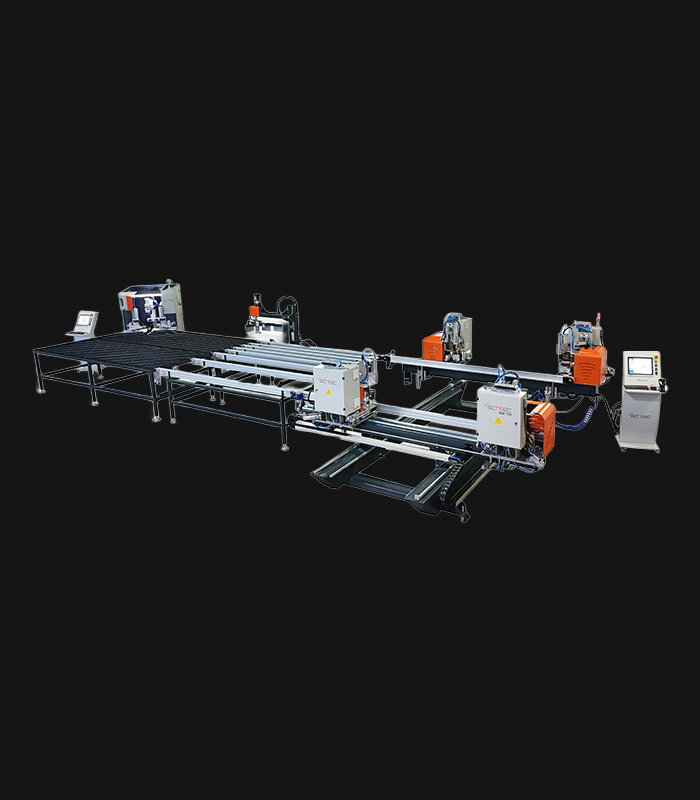

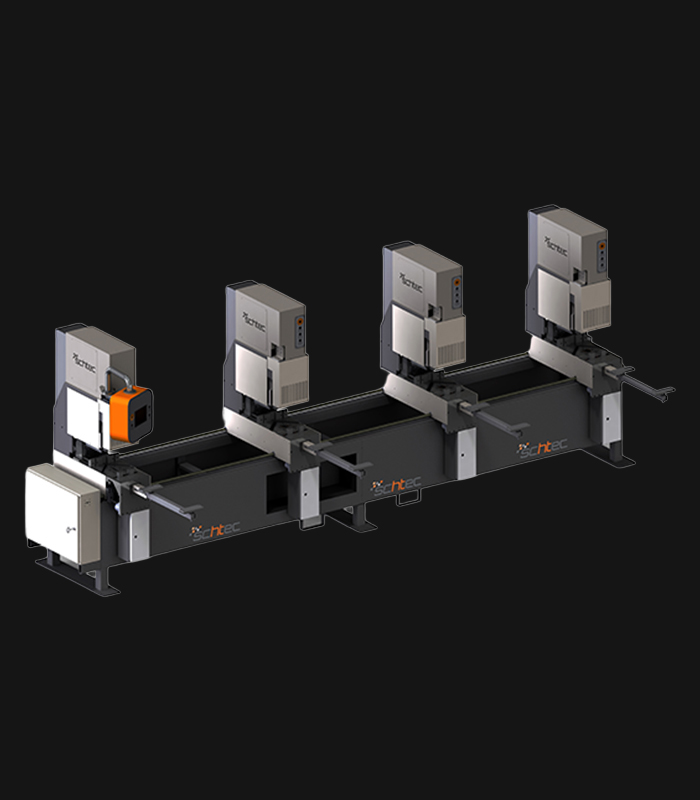

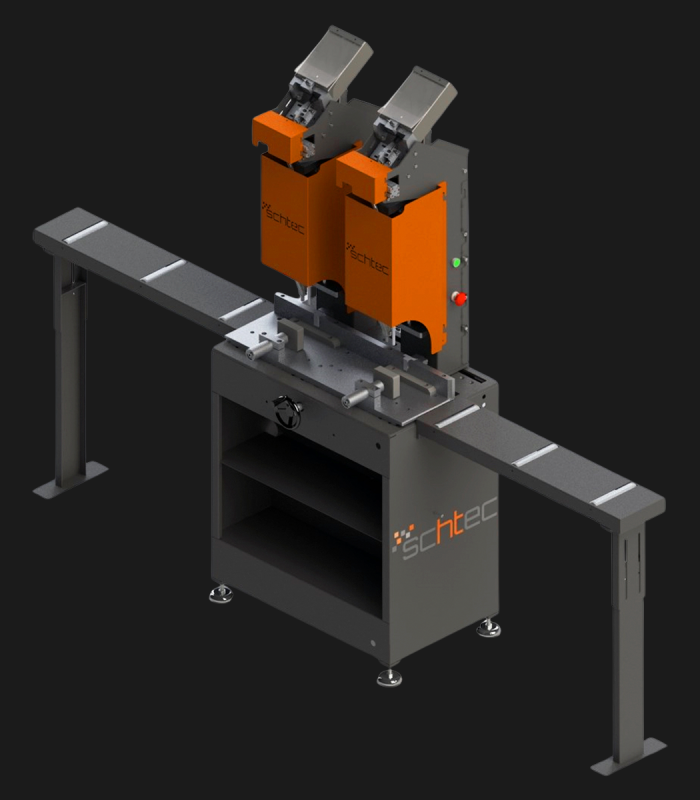

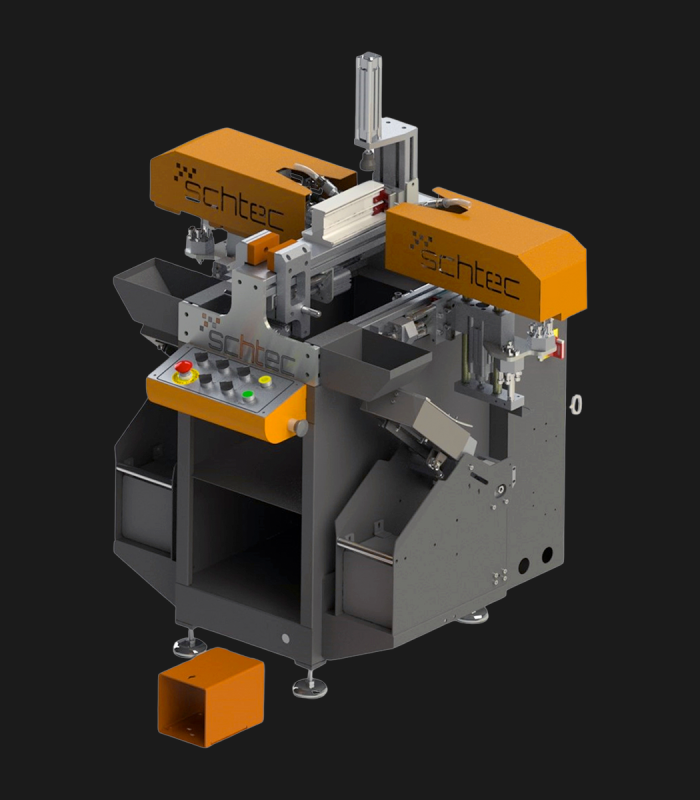

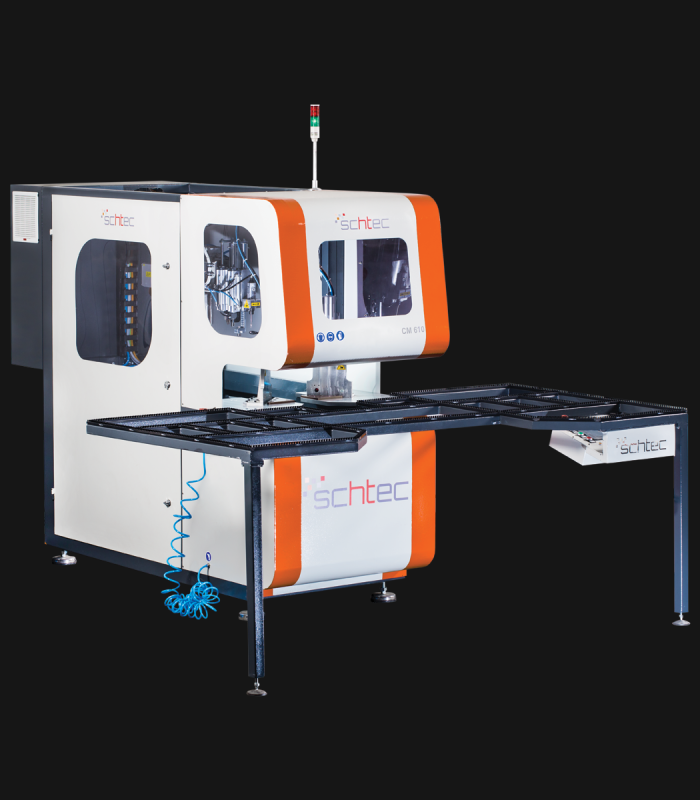

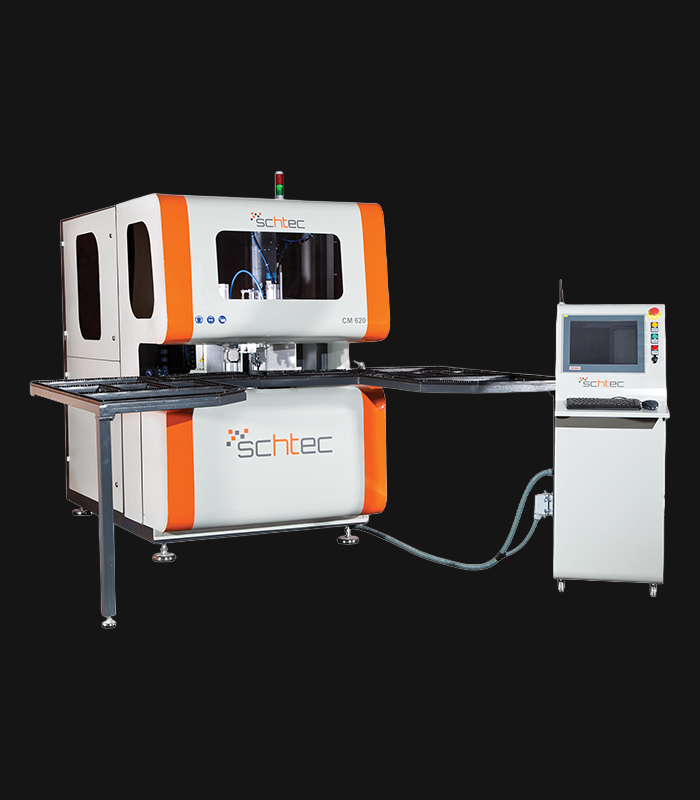

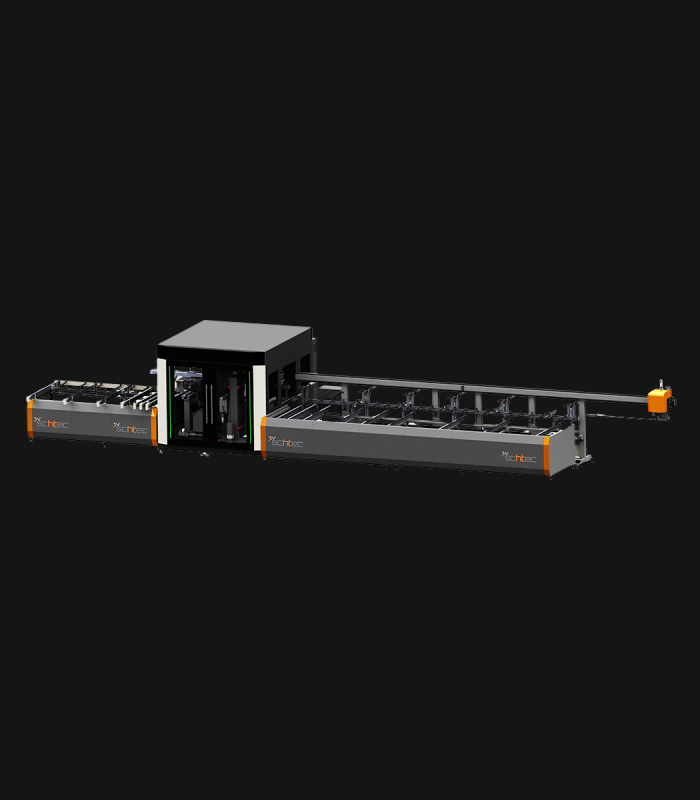

MT 256 Automatic Multiple End Milling Machine

The SCHTEC MT 256 offers precise, sensor-assisted milling for 1-6 PVC mullion profiles at once.

MT 256 Technical Specifications

| Power Supply | 400 V, 3 Ph, 50-60 Hz |

| Total Power | 1.65 kW (1.1 kW + 0.55 kW) |

| Air Pressure | 6-8 bar |

| Air Consumption | 60 l/min |

| Max. Profile Width | 120 mm |

| Max. Profile Height | 90 mm |

| Max. Knife Diameter | 130 mm |

| Max. End Milling Height | 90 mm |

| Max. End Milling Depth | 30 mm |

| Machine Height | 1,640 mm |

| Machine Length | 1,600 mm |

| Machine Width | 700 mm (1,460 mm with support table) |

| Machine Weight | 350 kg |

SKU:

MT-256

Category: End Milling Machines

Description

Standard Features

- End milling of the PVC and Aluminium transom profiles with high quality and precision

- Easy speed adjustment for knifes

- Easy stop point adjustment for end milling by rotary revolver system

- Very high safety protect by upper side cover

- Anti-Fracture protection on profile by speed adjustment during end milling process

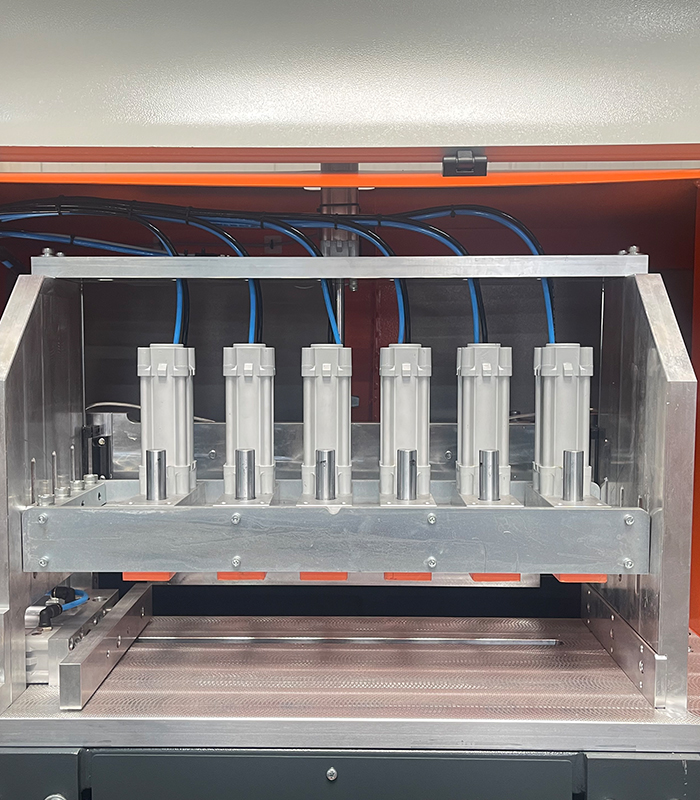

- Easy knife change system by plug&play knife changer

- Machine adjust axis way according to profile count automatically

- Onboard toolbox and safe box for spare knifes

- High quality and precision on end milling process by double clamper on side clamp system

- This system also ensure sliding of profiles and against to miter joint problems

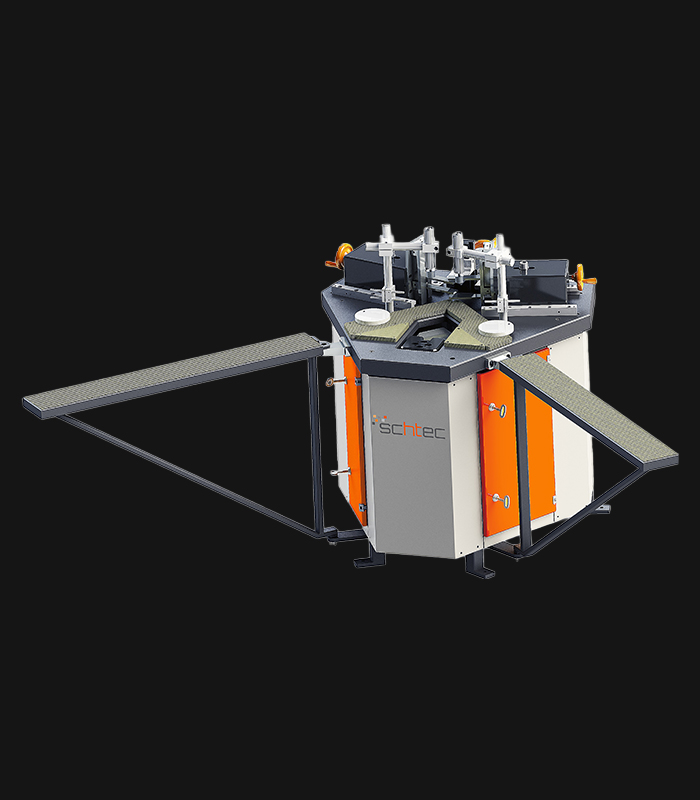

- Support arms provide up to 2,5 mt profiles for end milling

- Machine can work between 1 to 6 profile counts.

Product Description

The SCHTEC MT 256 is an automatic, sensor-assisted machine capable of precisely milling 1 to 6 PVC mullion profiles simultaneously. Its anti-slip system, pneumatic blade change, and 2.5-meter support stand ensure efficient and error-free operation. With a 1.65 kW motor, it fits well into compact production spaces. It is an ideal solution for sliding profiles.

FAQ

End Milling Machines for PVC Profiles

Frequently Asked Questions

Find quick answers to common questions about our End Milling Machines for PVC Profiles.

1. What is the role of an end milling machine in PVC profile production?

An end milling machine for PVC profiles is used to precisely cut, notch, or shape the ends of mullions, transoms, or frame pieces so they can be joined cleanly and flush. It removes material to create final geometry required for welding, corner joints, or mechanical connections. In window and door manufacturing, these operations ensure that profiles fit together tightly and securely. Without accurate end milling, assembly gaps or misalignments may occur, reducing product quality.

2. What are the advantages of a multiple end milling machine like the MT 256?

The MT 256 Automatic Multiple End Milling Machine can process up to six PVC profiles simultaneously, which greatly increases throughput. It offers features such as easy speed adjustment for knives, automatic axis adjustment according to profile count, and a plug‑and‑play knife change system. It also includes anti‑fracture protection and double clamping systems to maintain profile stability. These capabilities make it ideal for high‑volume production lines.

3. How does a single‑head machine like MT 252 differ in use from multiple‑head or automatic machines?

A single head machine is often favored for more specialized or smaller series production, where flexibility and setup simplicity are key. Although it can’t process multiple profiles at once like MT 256, it offers cost efficiency, easier maintenance, and quicker changeovers. For custom jobs or lower volumes, the MT 252 is sufficient and more economical. When paired with automation or feeding systems, it still integrates well into modern production workflows.

4. What features should one expect in a high‑quality PVC end milling machine?

Important features include adjustable cutting angles, robust clamping systems to hold the profile firmly in both vertical and horizontal directions, easy and safe knife change mechanisms, and automatic or manual speed adjustment. Integration with cooling or lubrication systems may also be offered for better finishing and longer tool life. Additional benefits such as protective covers, anti‑fracture controls, and minimal vibration help ensure consistent precision and operator safety.

5. What kind of maintenance is required to keep PVC end milling machines operating optimally?

Regular maintenance includes cleaning chips and debris from the cutting area, lubricating guide rails and moving parts, checking knife sharpness and replacing cutters before they dull, inspecting pneumatic or hydraulic clamps, and verifying that all safety covers are intact. Calibration checks and alignment verifications should be scheduled periodically. Proper maintenance helps maintain cutting quality, reduces downtime, and extends machine lifespan.