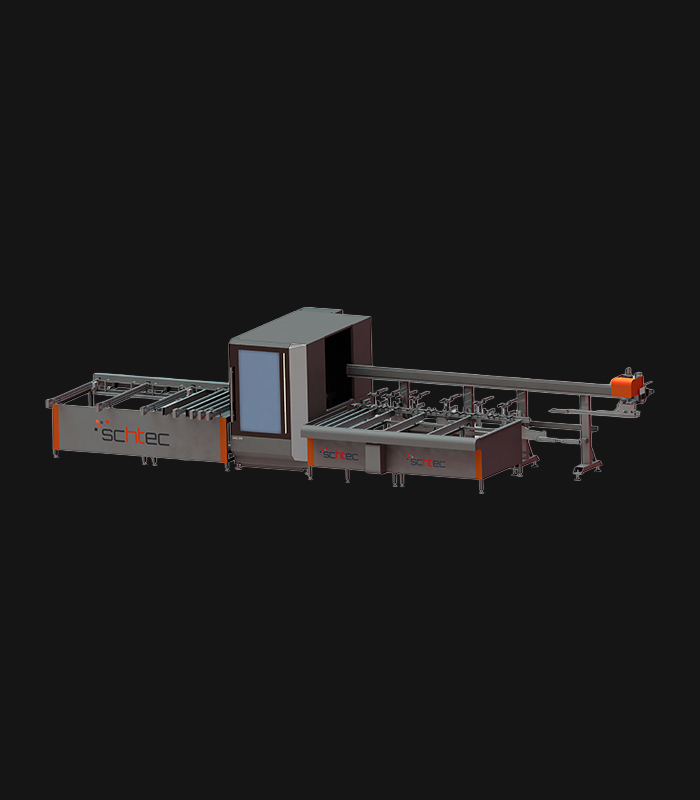

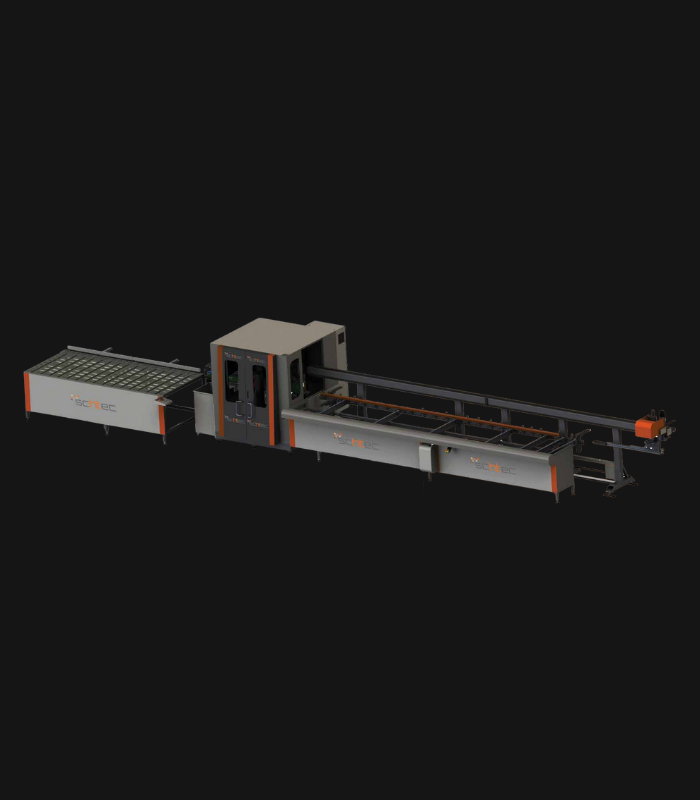

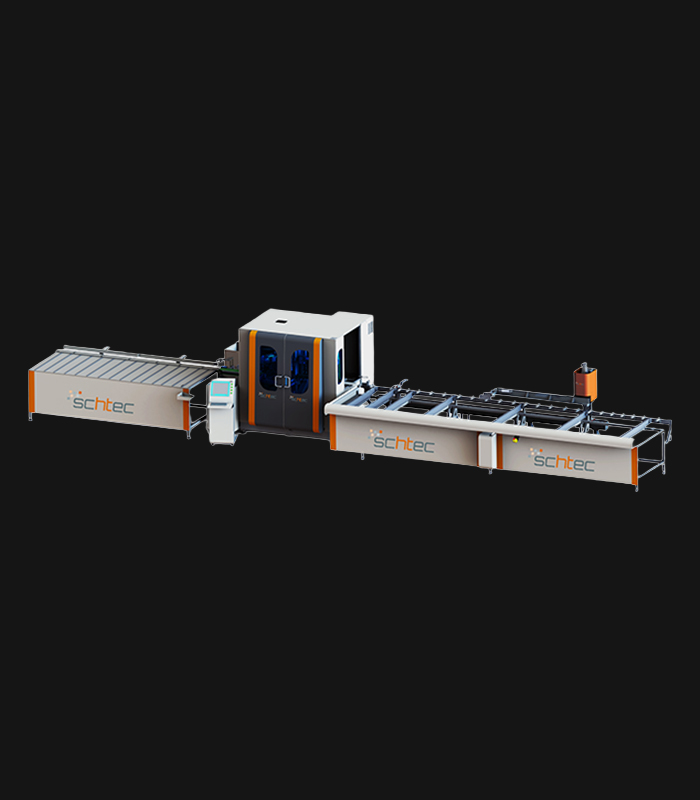

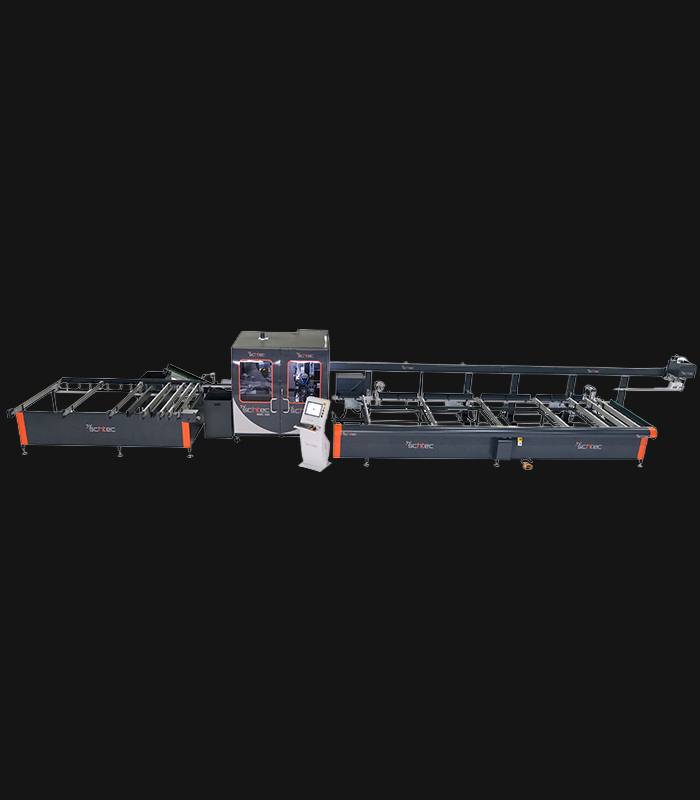

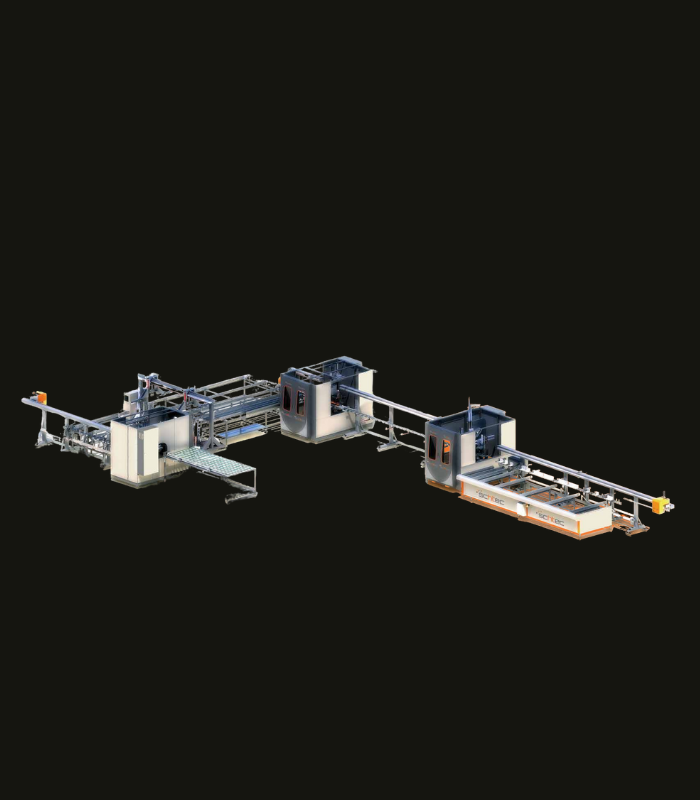

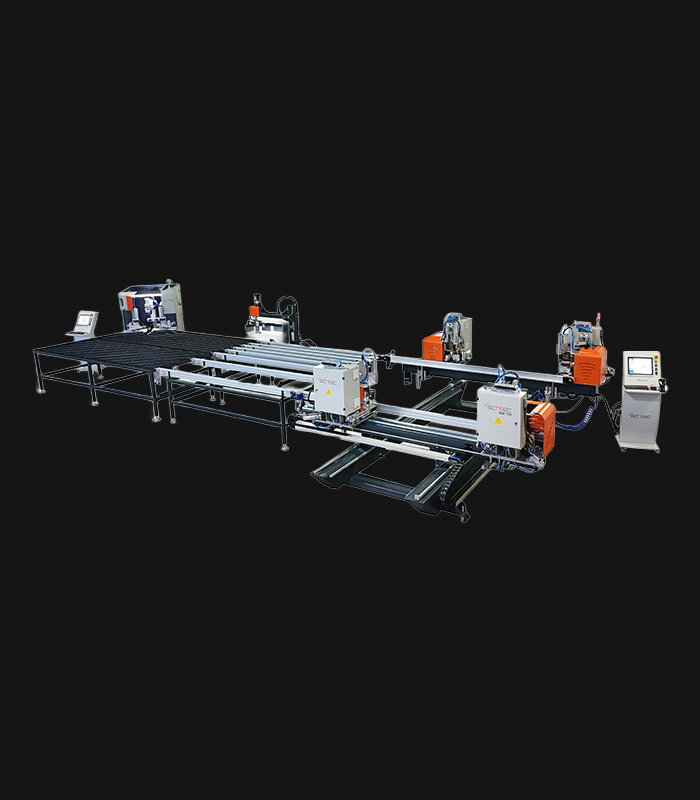

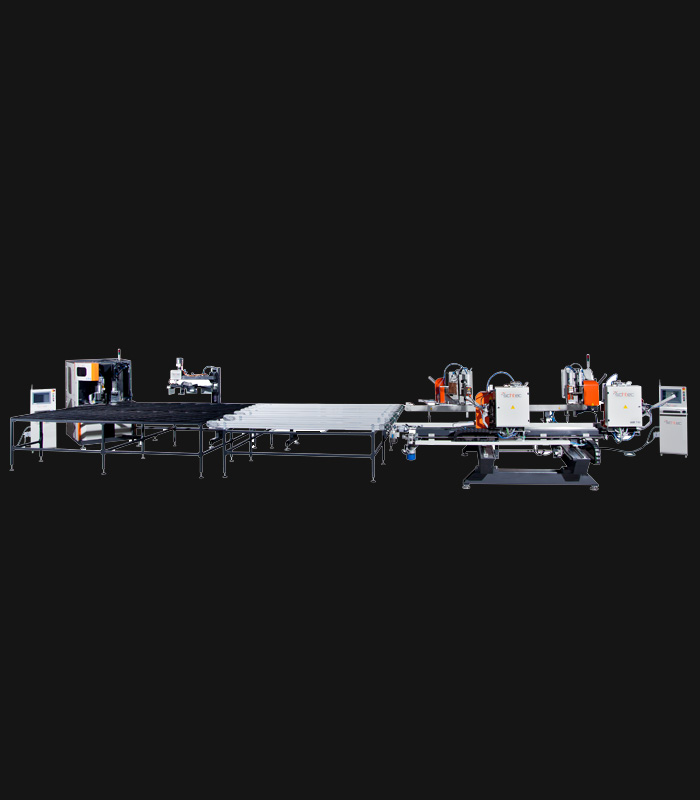

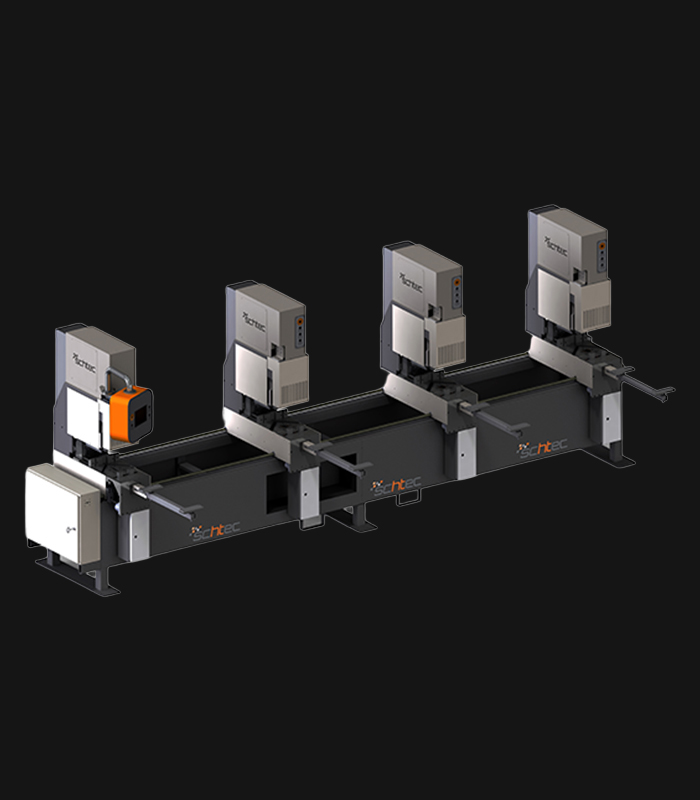

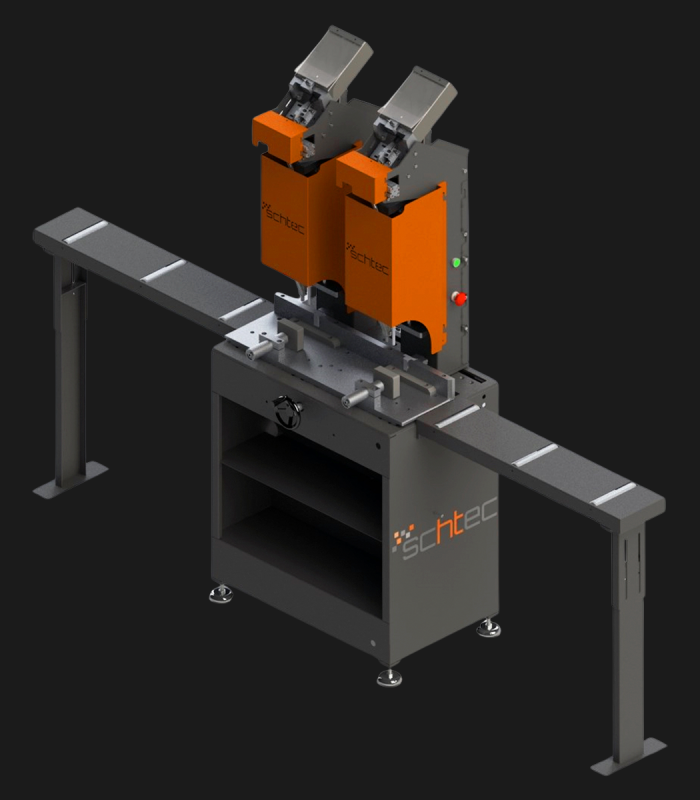

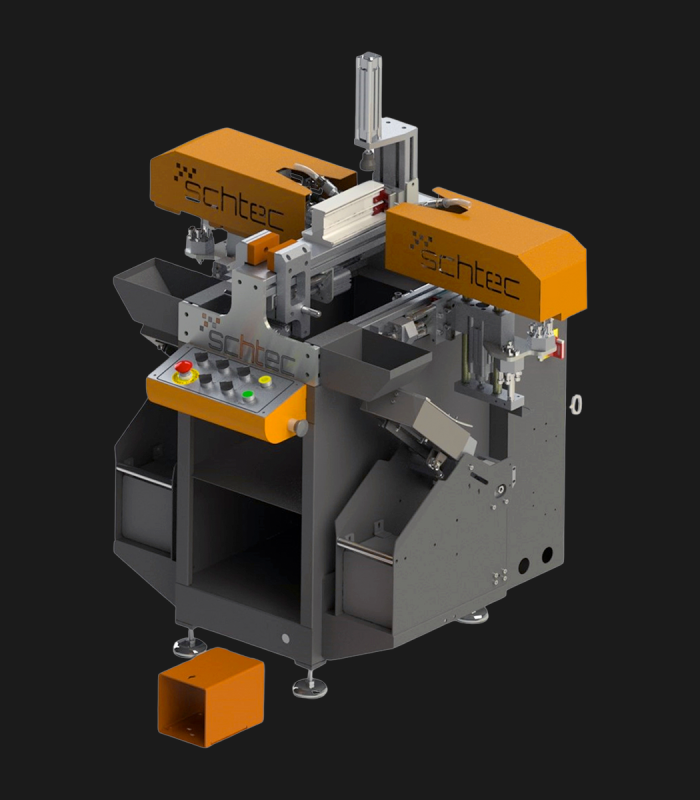

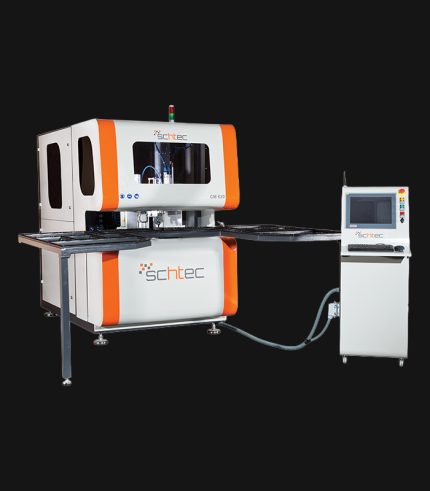

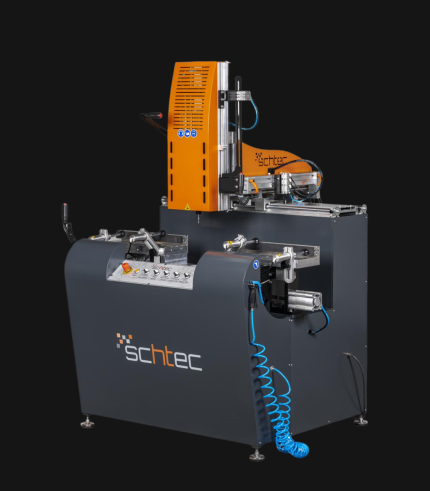

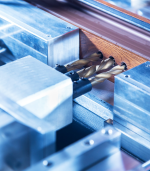

RC 210 Copy Router Machine with the Triple Drill

Schtec RC 210: Copy router for PVC and aluminum profiles. 0.75 kW motor, 12,000 rpm, triple drilling, pneumatic clamping. Compact and efficient.

RC 210 Technical Specifications

| Power Supply | 400 V, 3 Ph, 50-60 Hz |

| Total Power | 1.85 kW, 5 A |

| Air Pressure | 6-8 bar |

| Air Consumption | 15 lt./min |

| Milling Motor Power | 0.75 kW |

| Milling Motor Speed | 12,000 rpm |

| Triple Drilling Motor Power | 1.1 kW |

| Triple Drilling Motor Speed | 900 rpm |

| Milling Area | 250 mm x 120 mm |

| Max. Slot Milling Length | 250 mm |

| Max. Milling Depth | 120 mm |

| Max. Profile Dimensions | 110 mm x 120 mm |

| Machine Width | 720 mm (+1,000 mm Right and Left Profile Centering System) |

| Machine Height | 1,470 mm |

| Machine Length | 1,050 mm |

| Machine Weight | 160 kg |

Standard Features

- Opens tilt system channel, drain slot, lock cylinders and door handle holes on PVC and Aluminium profiles

- 1:1 ratio pattern transfer onto a profile from a template

- Milling process is done by a high speed frequency controlled motor

- Milling with adjustable measurement apparatus without using a template

- Using 2 different size (5mm-8mm) bits on single template with 2 different step.

- Pneumatic Profile Clamping

Optional Features

- Cooling system for aluminium profiles (CA 944)

- Left and right measurement centering system

Product Description

The Schtec RC 210 is a versatile copy router designed for both PVC and aluminum profiles. It delivers precise 1:1 template milling with a 0.75 kW motor operating at 12,000 rpm and includes a 1.1 kW drilling motor for manual triple drilling of handle slots. Equipped with 5-8 mm guide options, adjustable stops, and a pneumatic clamping system, the RC 210 ensures safe, flexible, and accurate machining. Its compact 160 kg design makes it suitable for workshops of all sizes, while global exports to over 65 countries prove its reliability and quality under the Schtec brand.

Frequently Asked Questions

Find quick answers to common questions about our Copy Router & Drilling Machines for PVC Profiles