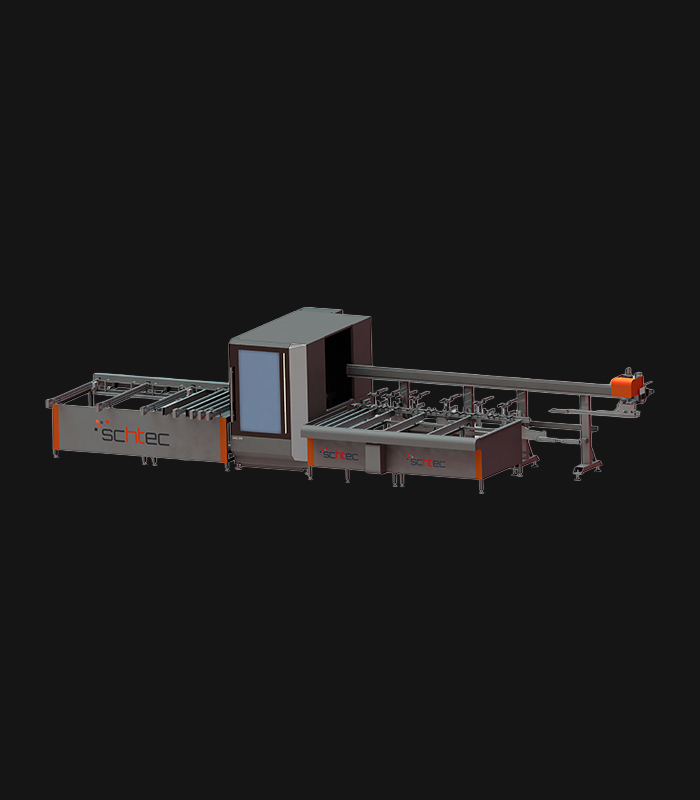

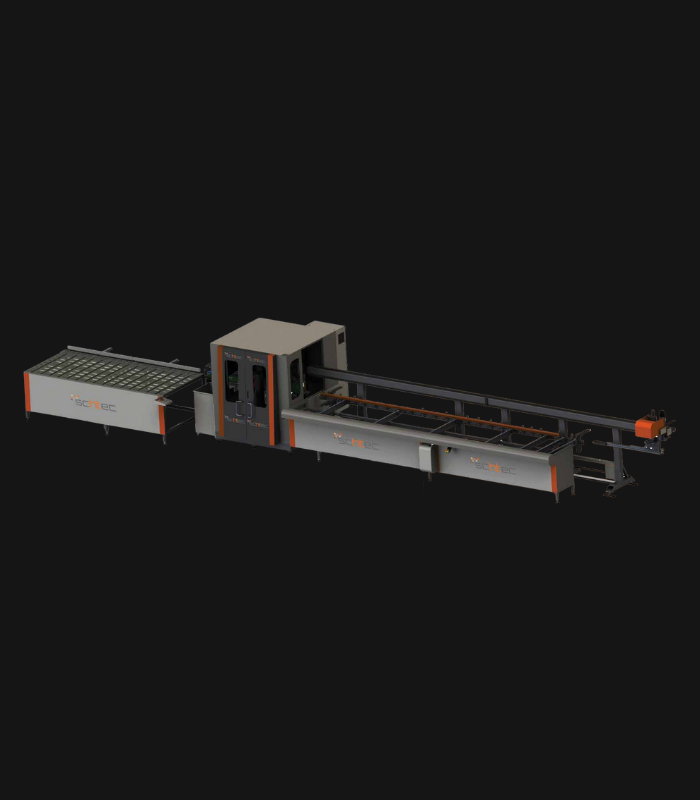

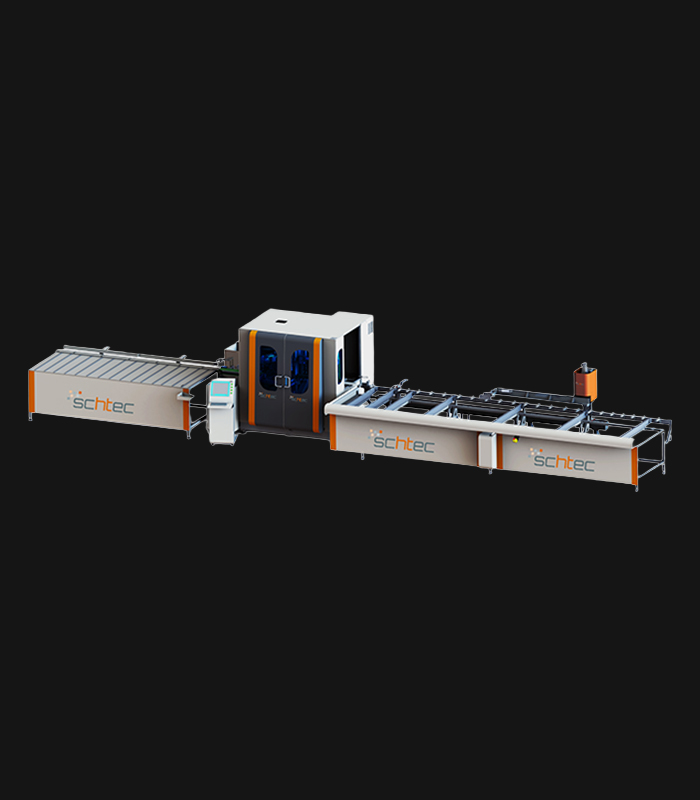

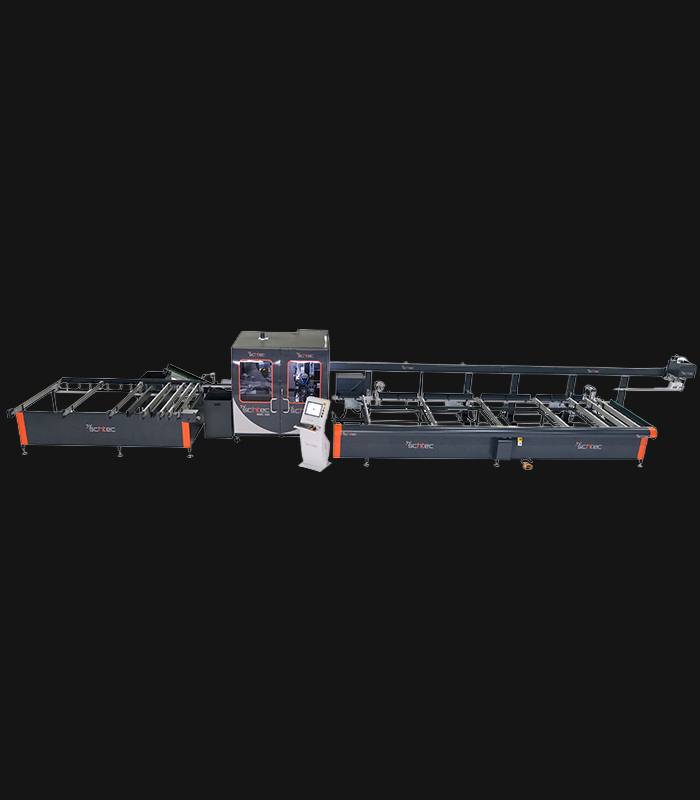

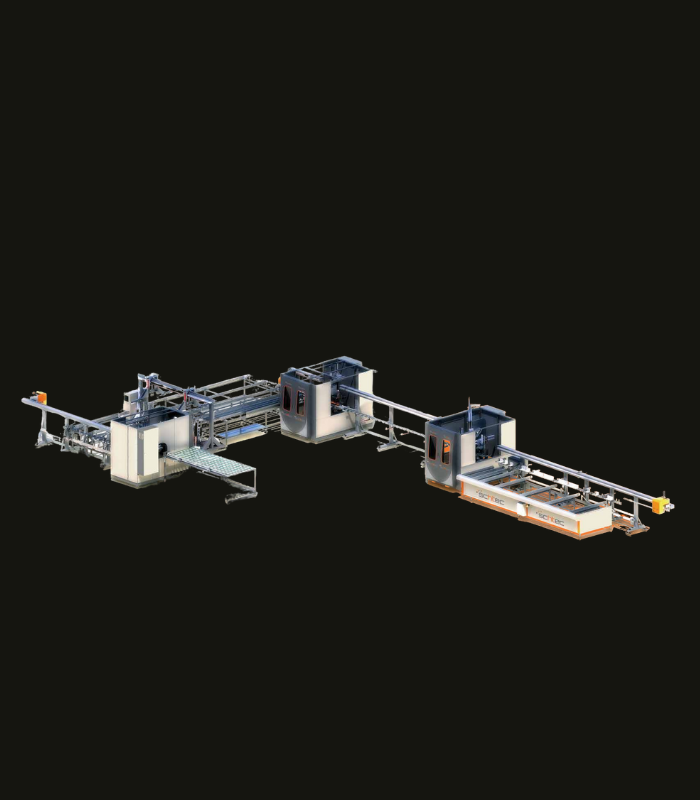

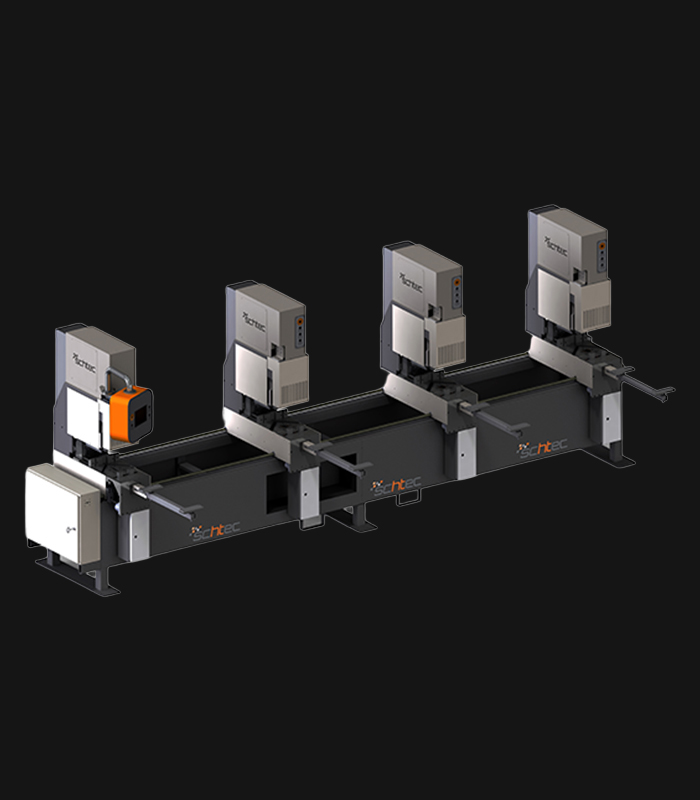

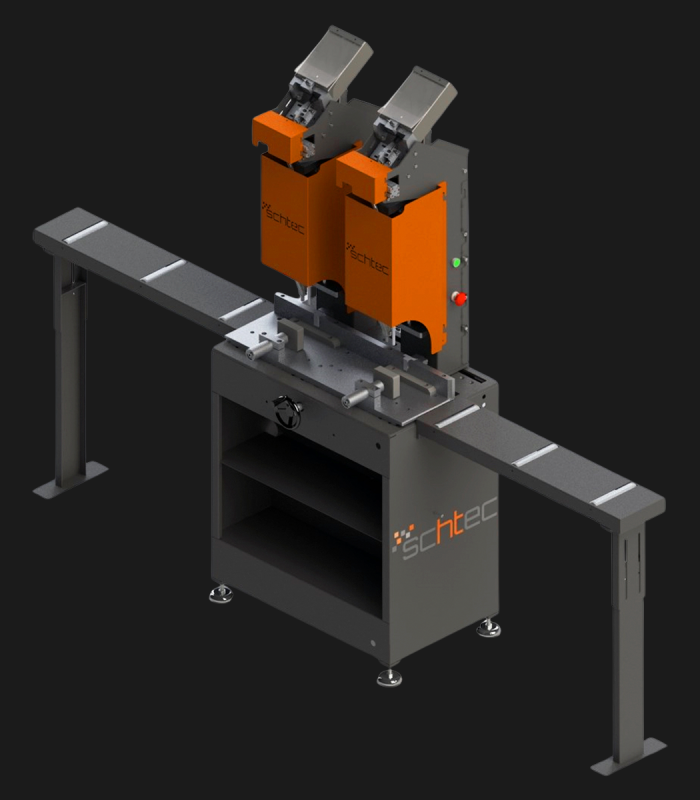

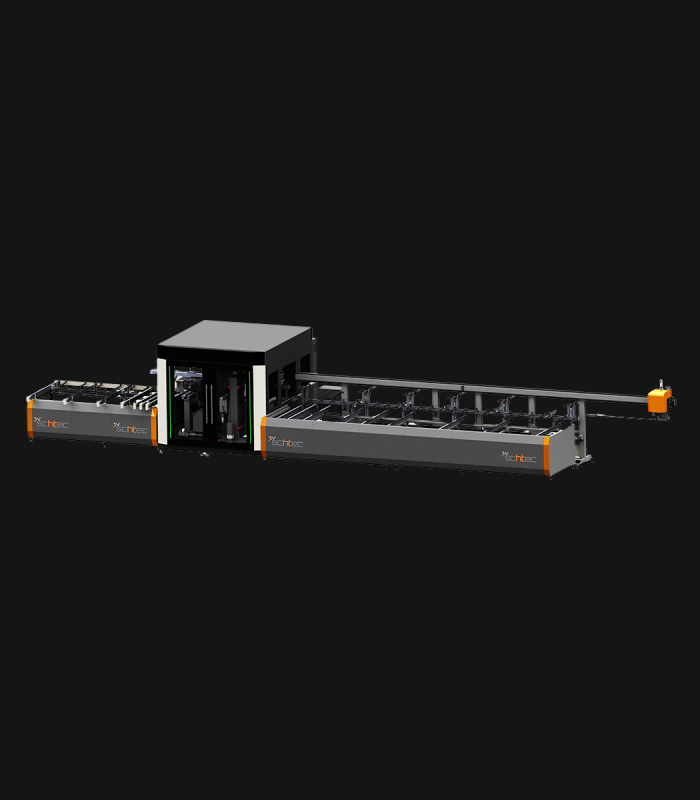

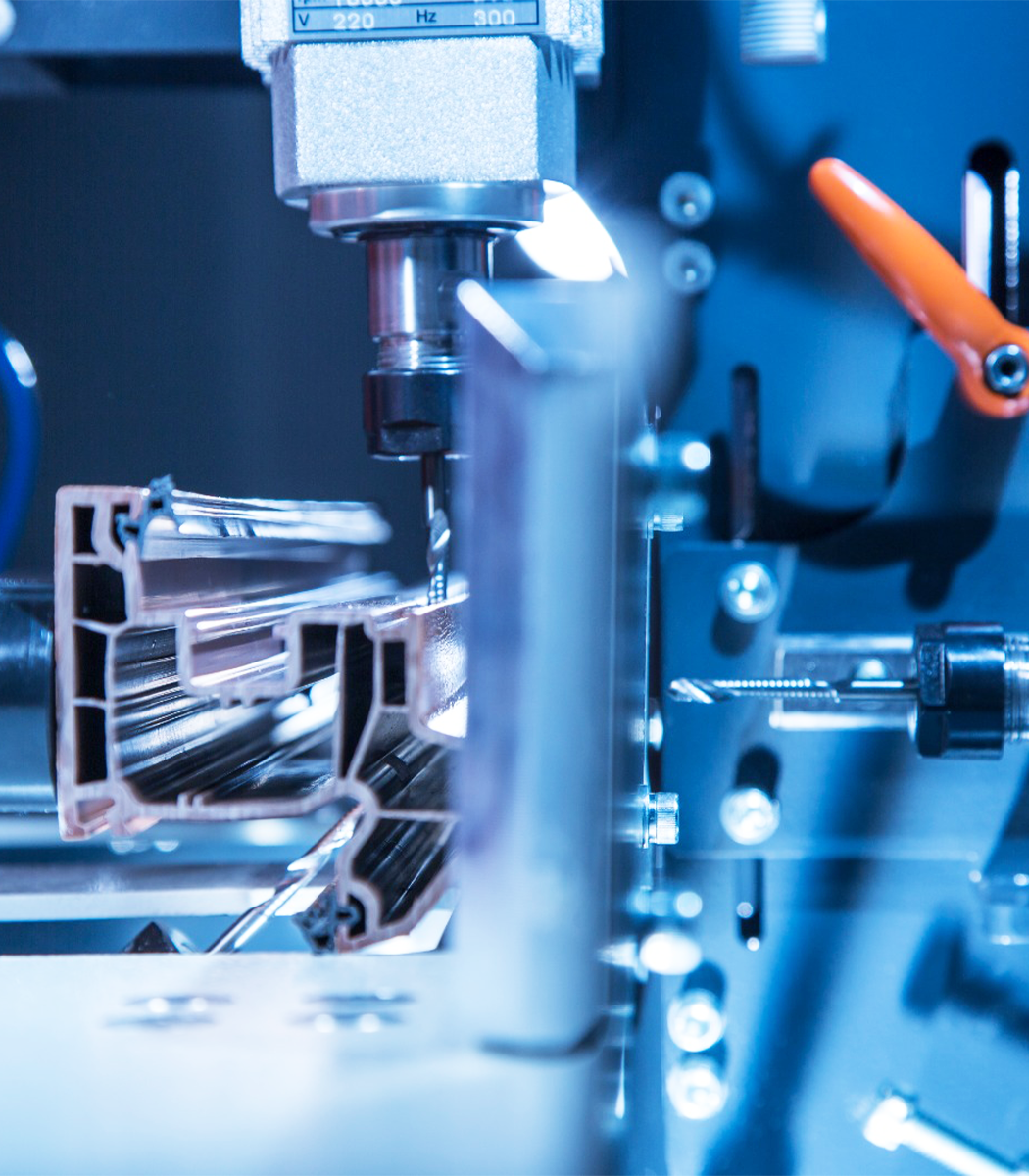

WS 220 Automatic Triple Water Slot Router

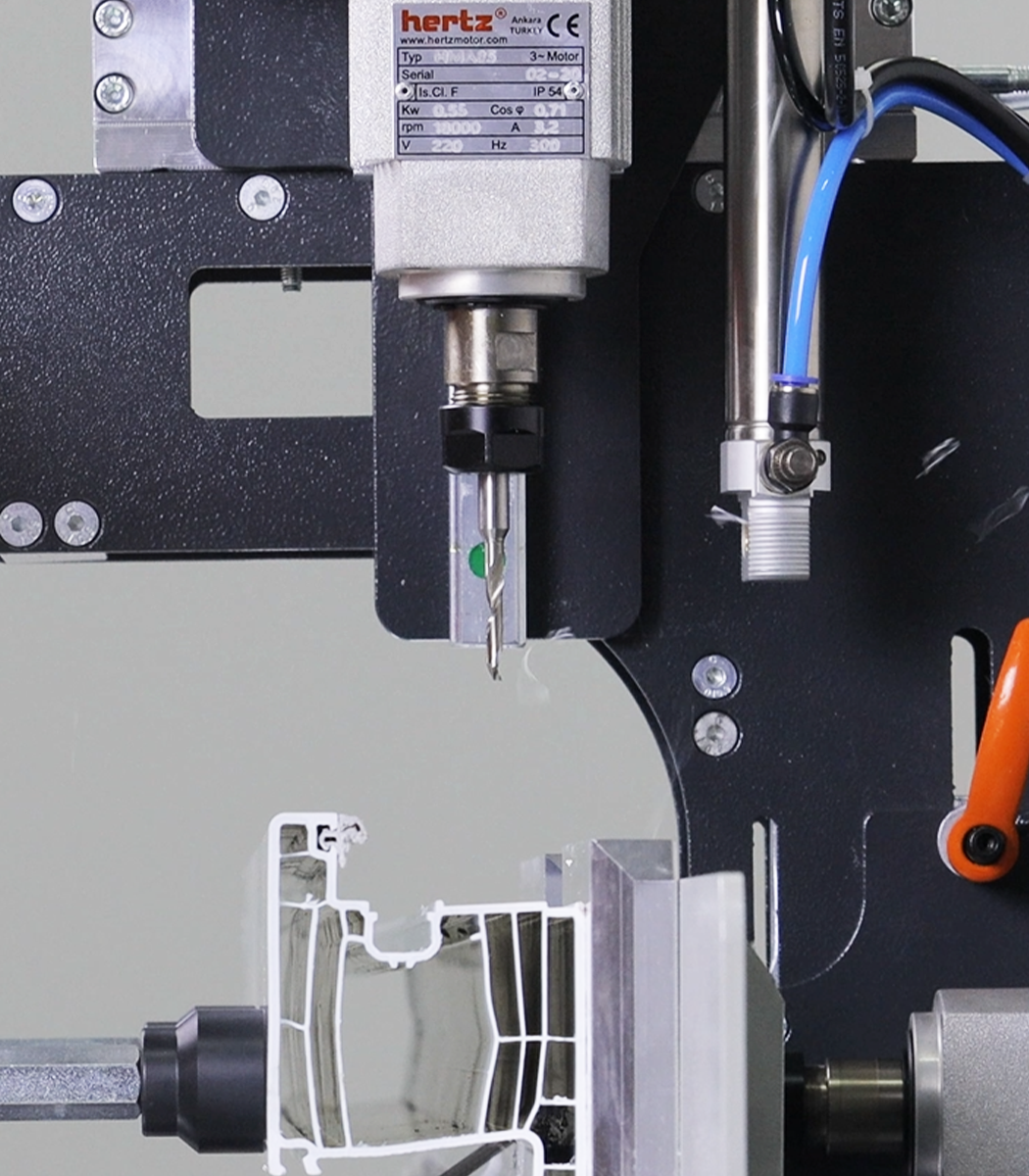

Schtec WS 220 PVC water drainage with 3x 18,000 rpm motors, pneumatic clamping, lever-arm. Compact, 1.65 kW, exported to 65+ countries.

WS 220 Technical Specifications

| Power Supply | 230 V, 3 Ph, 50-60 Hz |

| Total Power | 1.65 kW (0.55 kW x 3) |

| Air Pressure | 6-8 bar |

| Air Consumption | 24 lt./min |

| Spindle Speed | 18,000 rpm |

| Max. Milling Length | 40 mm |

| Max. Milling Depth | 30 mm |

| Machine Width | 1,210 mm |

| Machine Height | 1,040 mm |

| Machine Length | 550 mm |

| Machine Weight | 280 kg |

SKU:

WS-220

Category: Copy Router & Drilling Machines

Description

Standard Features

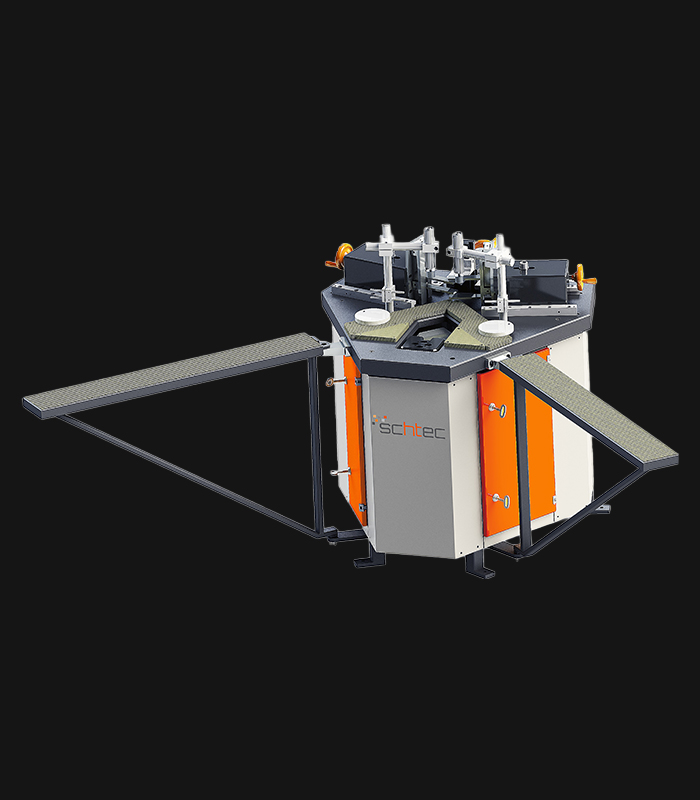

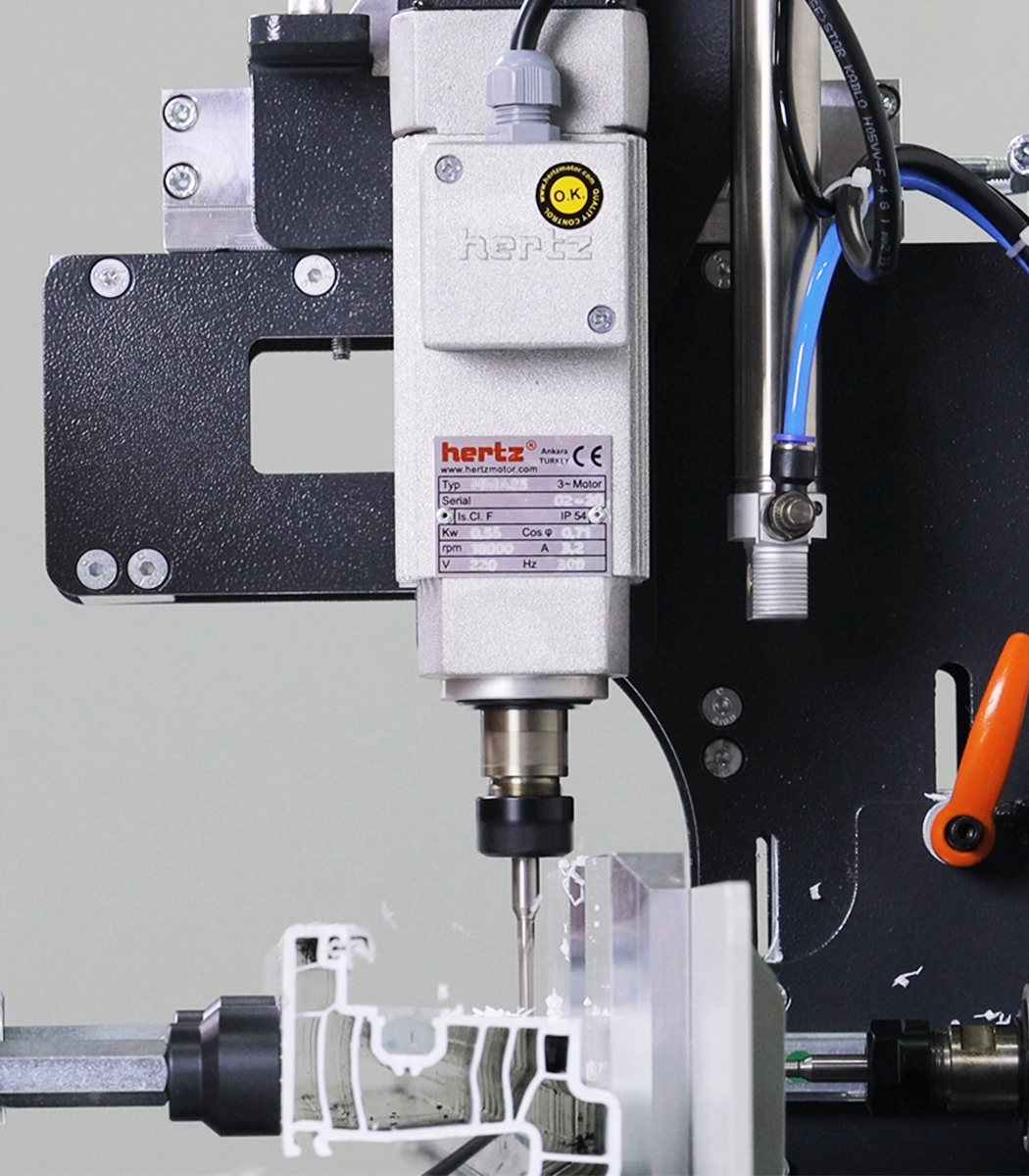

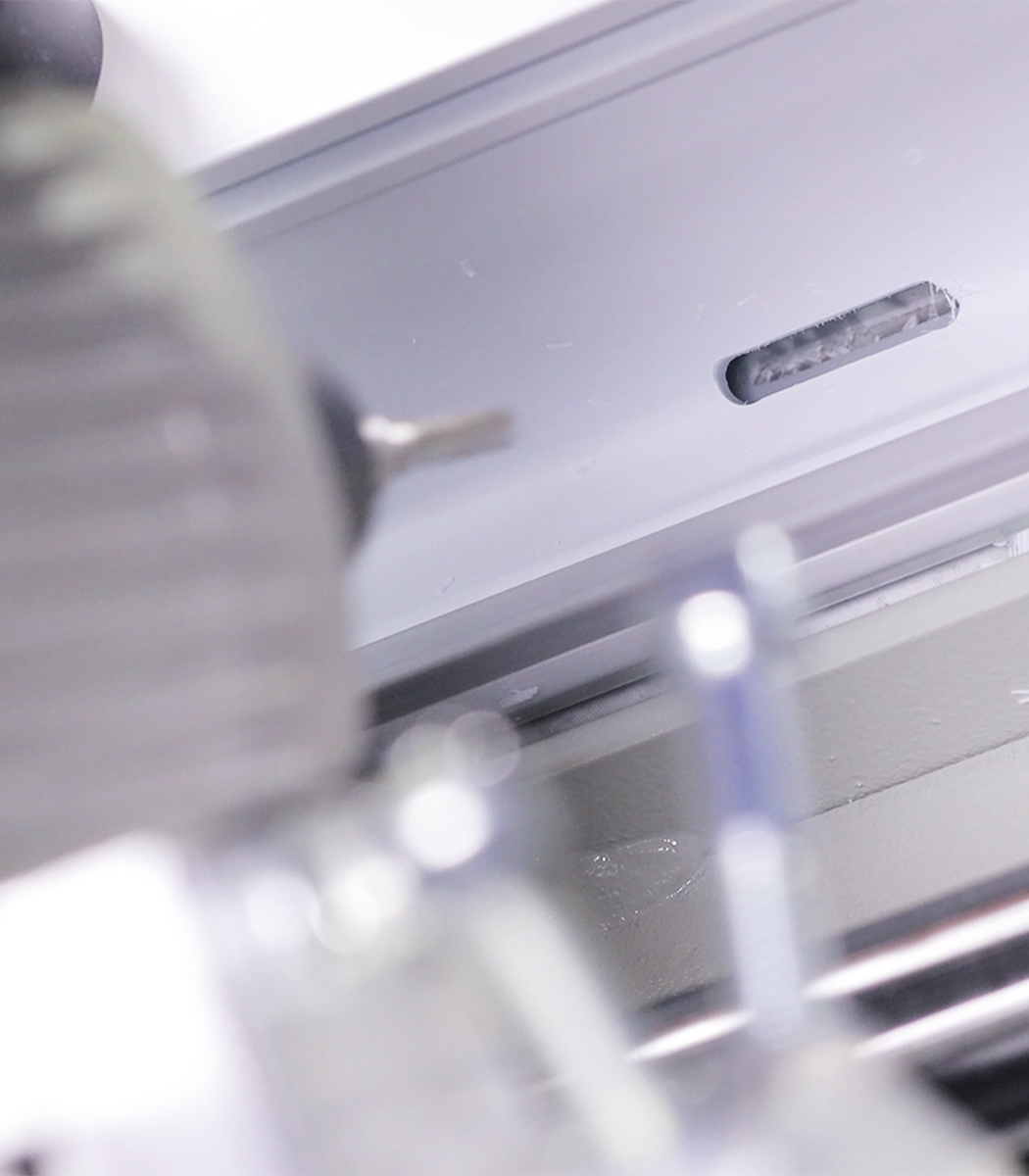

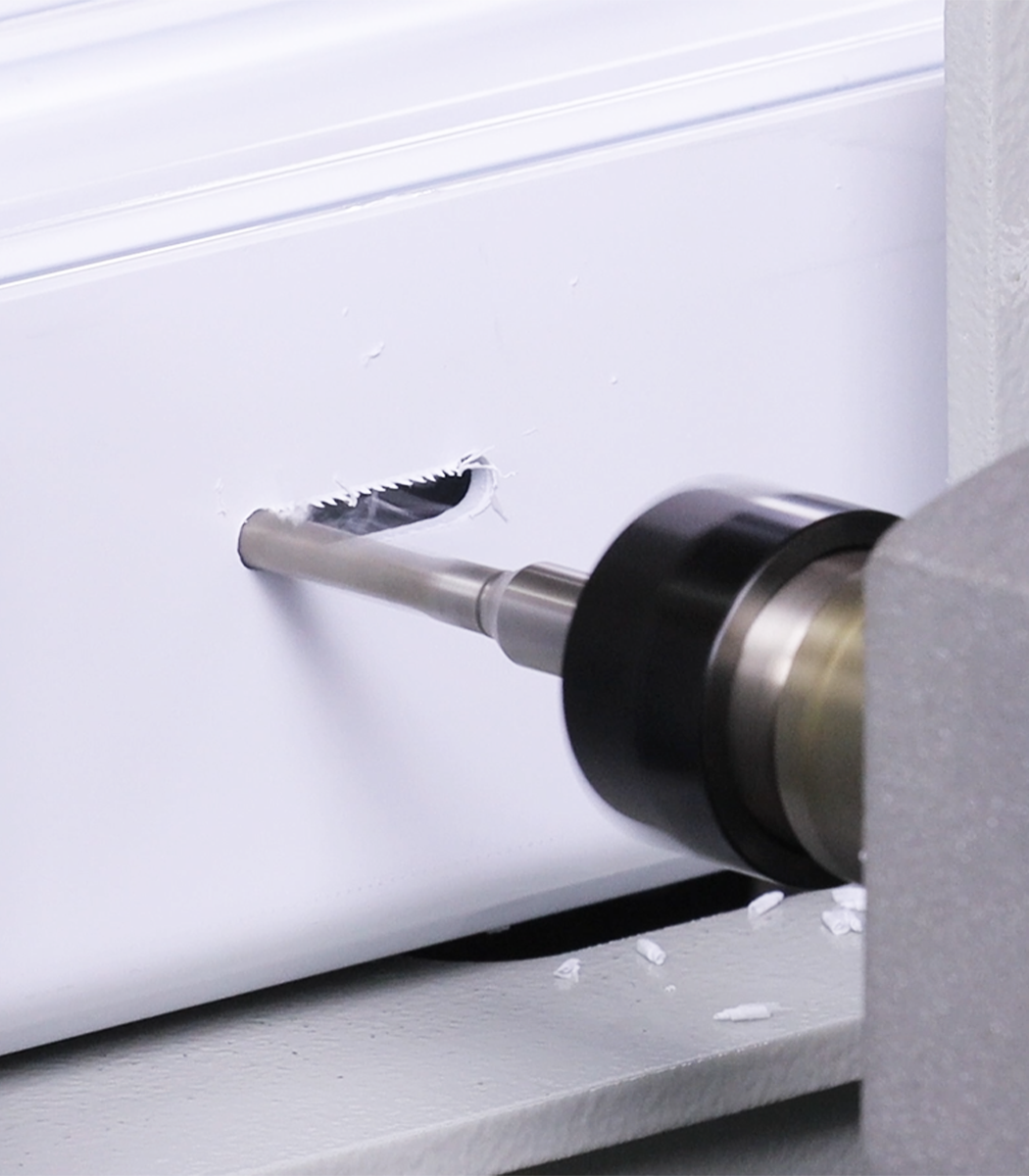

- Opens water drain slots including angled, horizontal and vertical slots on PVC profiles with three motors

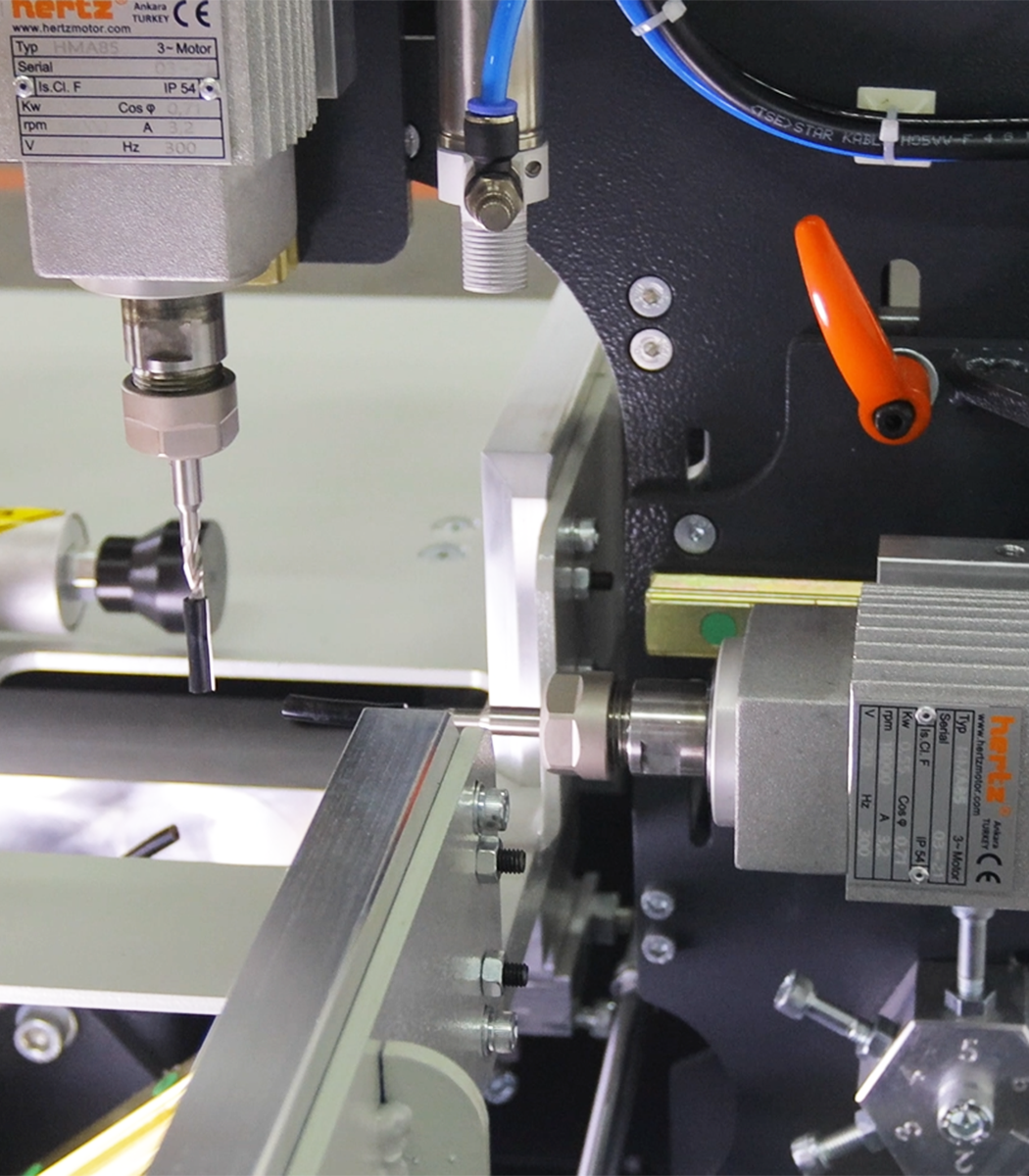

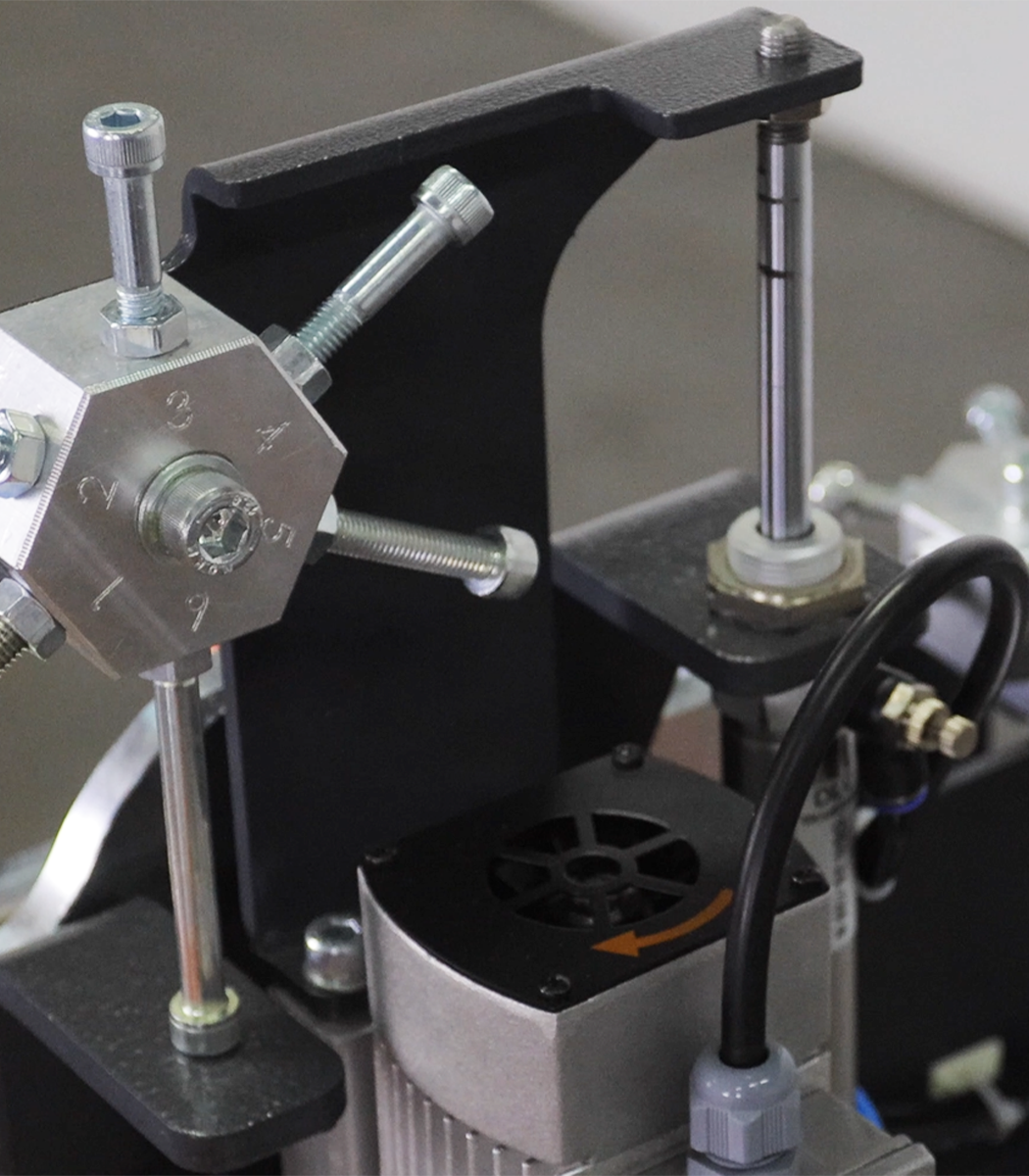

- Has three of high speed frequency controlled motors

- Motors can work independently of each other

- Independently adjustable routing speed for each motor

- Pneumatic profile clamping

- Fixed motors, Movable main tray

- Profiles can placed vertically or horizontally

- Fast angle changing system for angled motors

- Ventilation hole or drain slots selection

Product Description

The Schtec WS 220 features three independent motors running at 18,000 rpm to open water drainage channels in PVC profiles. Capable of processing at various angles, the machine operates quickly and safely with pneumatic profile clamping and a lever-arm mechanism. With a 1.65 kW motor and energy-efficient operation, the WS 220 fits well in compact spaces and is exported to over 65 countries under the Schtec brand.

FAQ

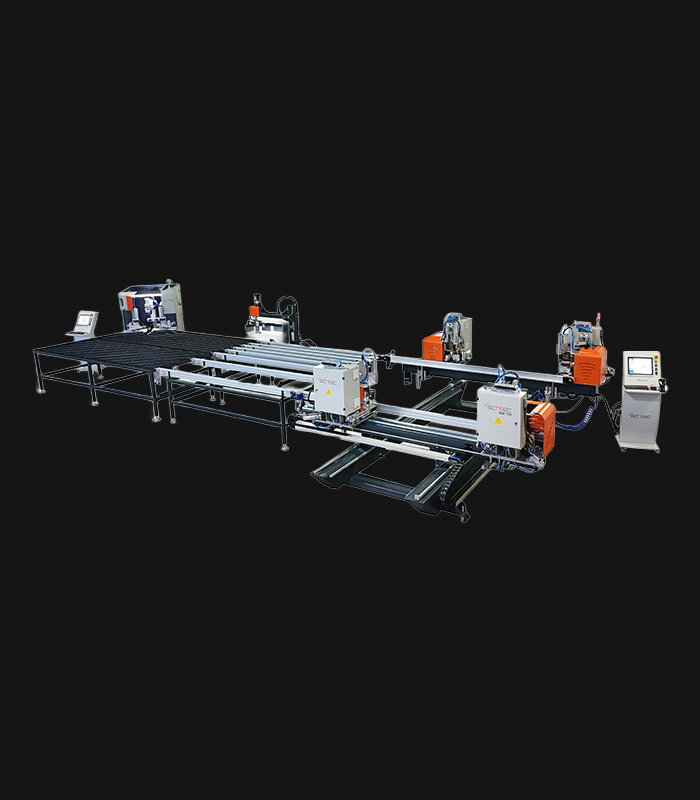

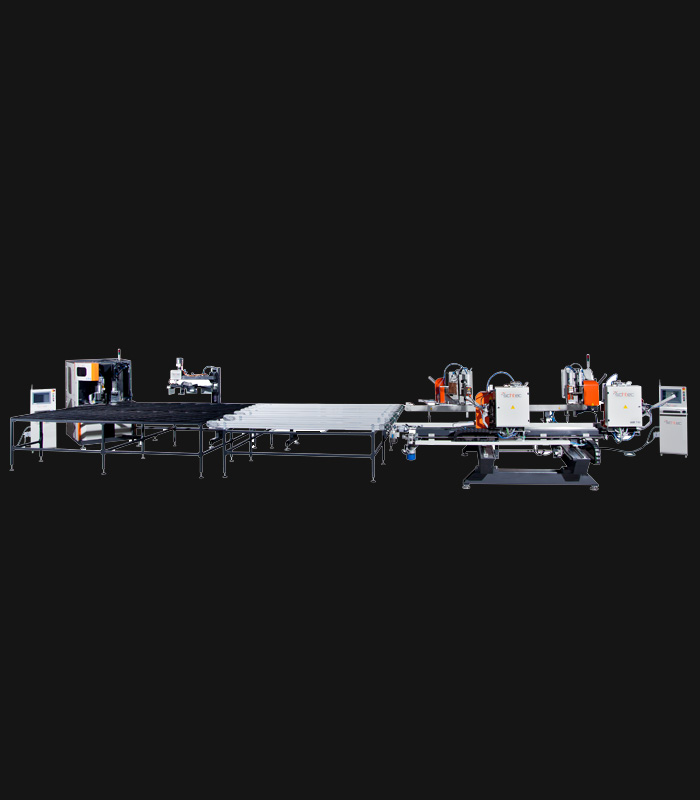

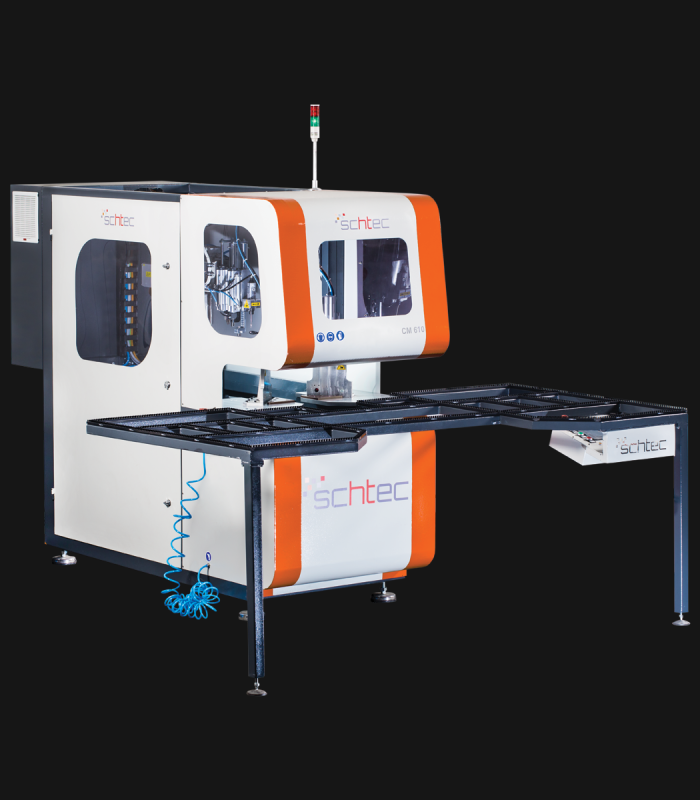

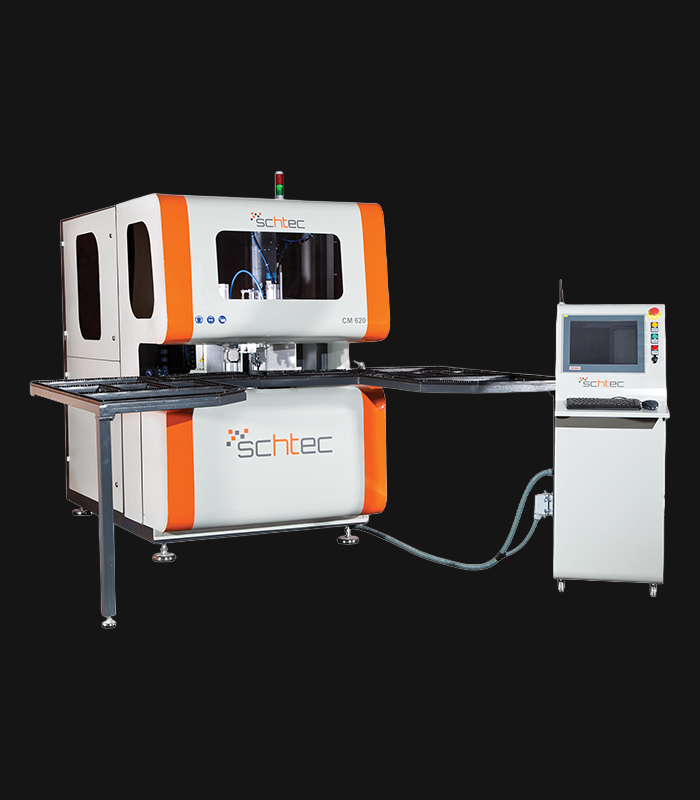

Copy Router & Drilling Machines for PVC Profiles

Frequently Asked Questions

Find quick answers to common questions about our Copy Router & Drilling Machines for PVC Profiles

1. What is the main purpose of a copy router and a water slot machine for PVC profiles?

A copy router, like the Schtec RC 208 or RC 210, is designed to mill precise openings for hardware such as handles, locks, and espagnolettes by tracing a template. A water slot machine, like the WS 220, is a specialized router used to create angled and straight drainage channels that prevent water from accumulating inside the PVC frame.

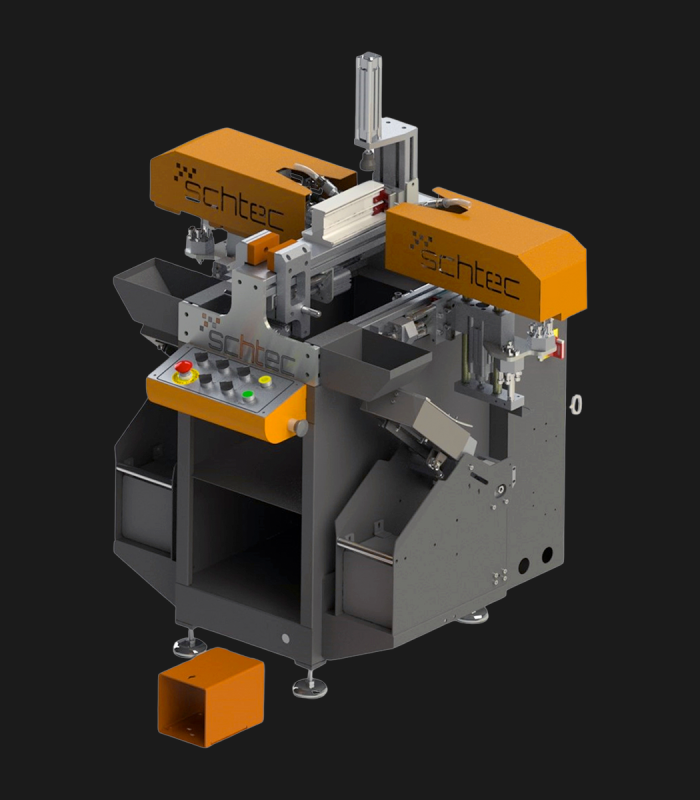

2. What is the key advantage of the RC 210 model compared to the RC 208?

Both machines perform high-quality copy routing. The main advantage of the RC 210 is its integrated manual triple drilling unit. This feature allows the operator to drill all three handle holes at once, even through the reinforcement steel inside the profile, which significantly saves time during hardware installation. The RC 208 is a dedicated copy router without this triple drilling capability.

3. What makes the WS 220 machine so effective for water drainage slots?

The WS 220 is highly effective because it uses three independent, high-speed routing motors that can operate simultaneously on angled, vertical, and horizontal planes. This allows it to create complex and precise water drainage paths in a single, quick operation. The motors' speeds and positions are independently adjustable, offering great flexibility for different PVC profile designs.

4. Can the triple drilling unit on the RC 210 drill through reinforcement steel?

Yes, absolutely. The triple drilling unit on the RC 210 is specifically designed to be powerful enough to drill through both the PVC and the reinforcement steel inside the sash profile in a single manual operation. This ensures a fast and precise preparation for handle assembly.

5. Do these machines always require a template to operate?

While their primary function is to copy a template at a 1:1 ratio, models like the RC 208 and RC 210 also come equipped with adjustable measurement stops and apparatus. This allows operators to perform straight routing operations, such as creating simple slots or channels, without needing a template, providing extra flexibility for various tasks.