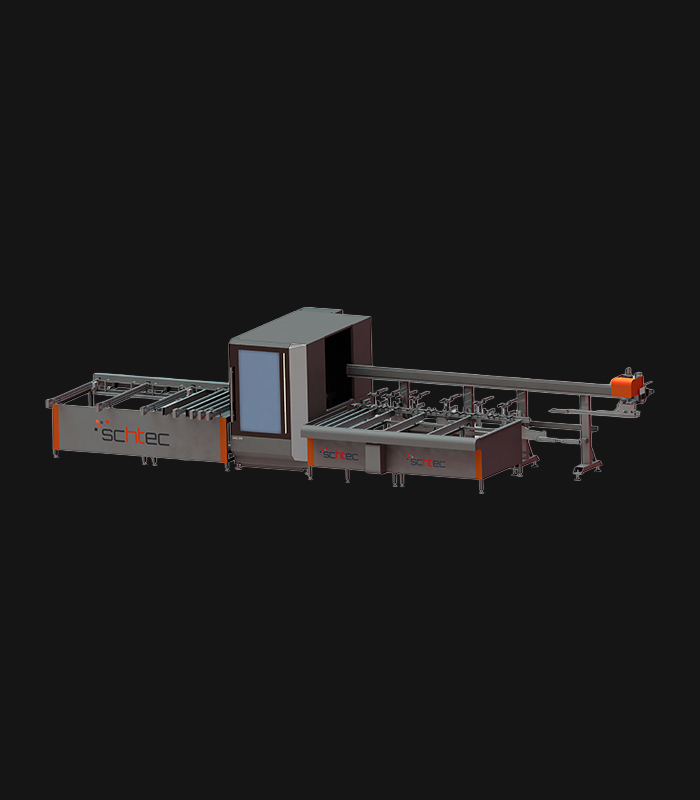

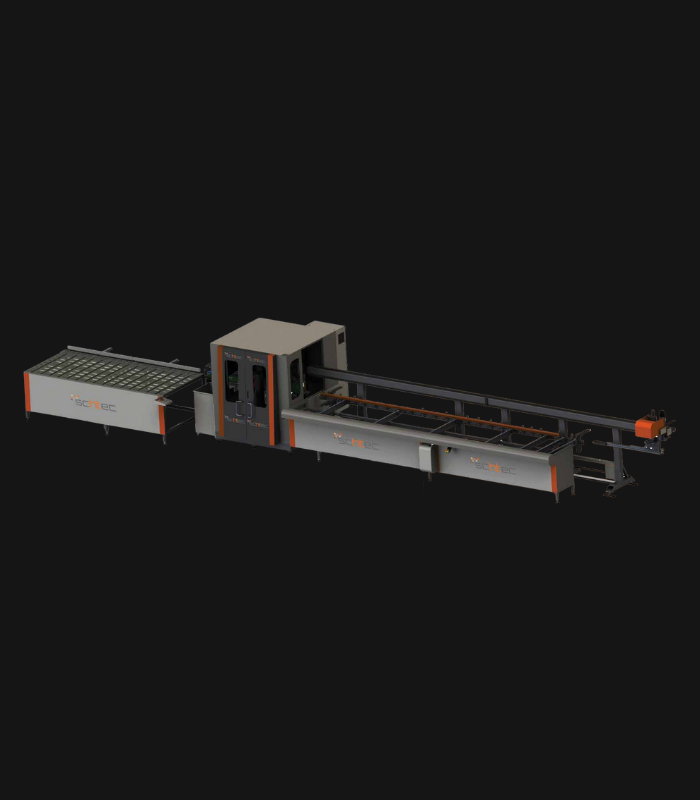

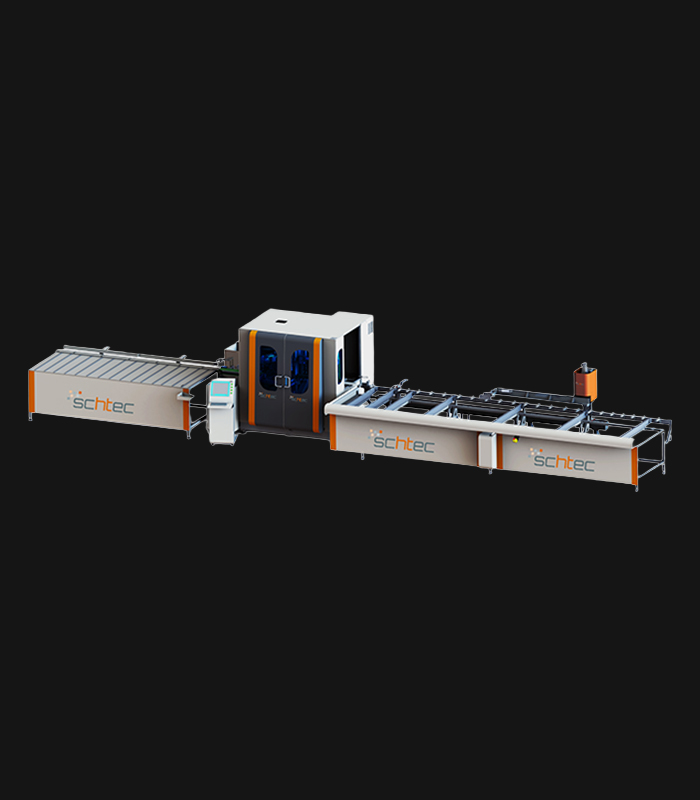

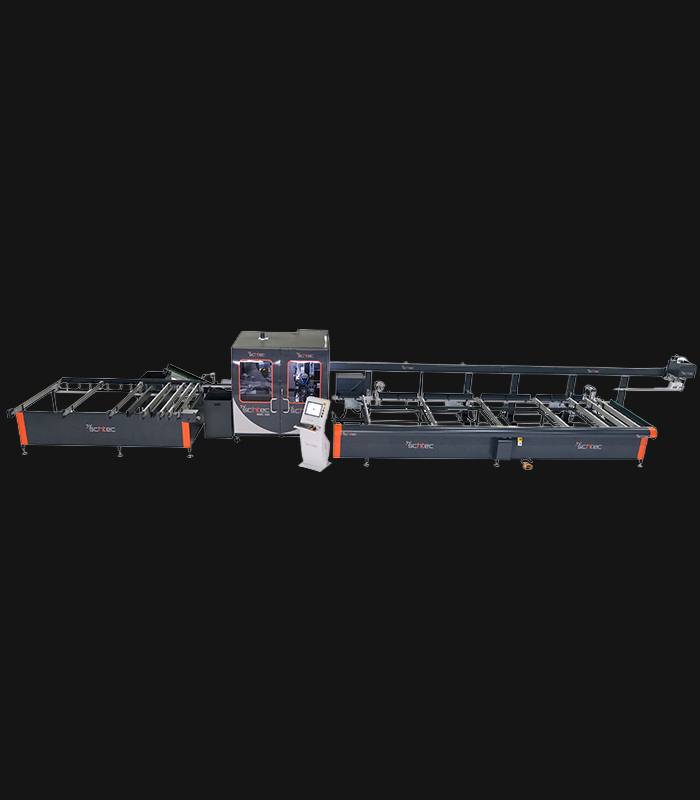

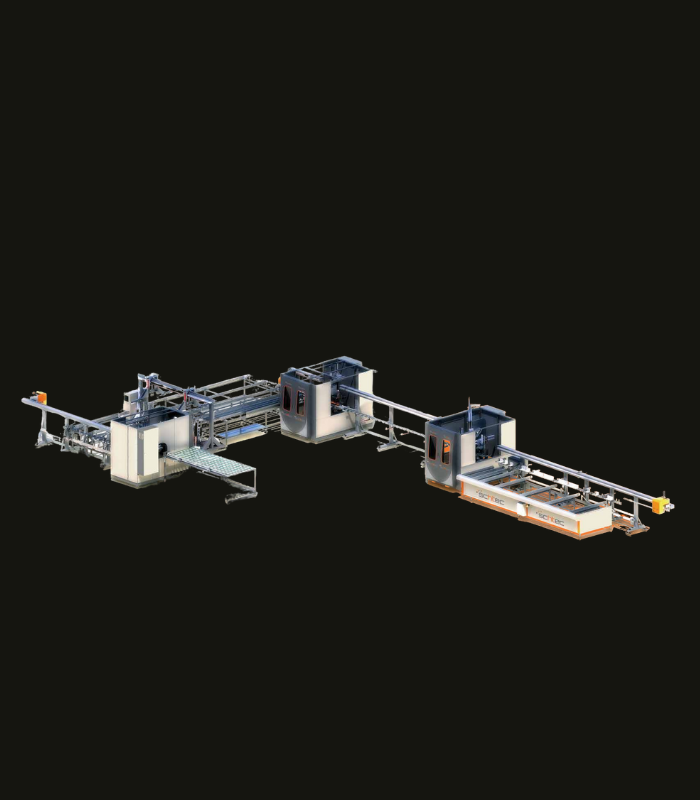

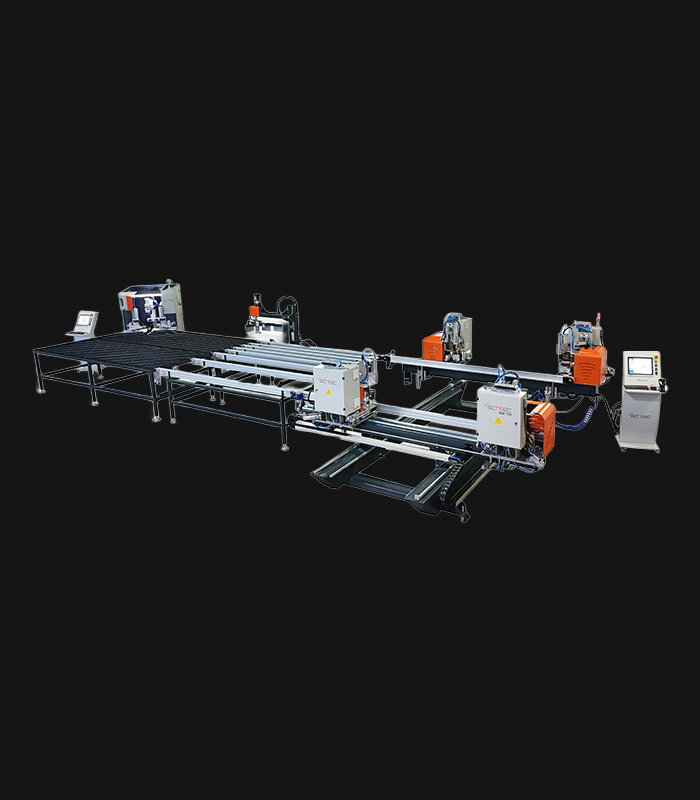

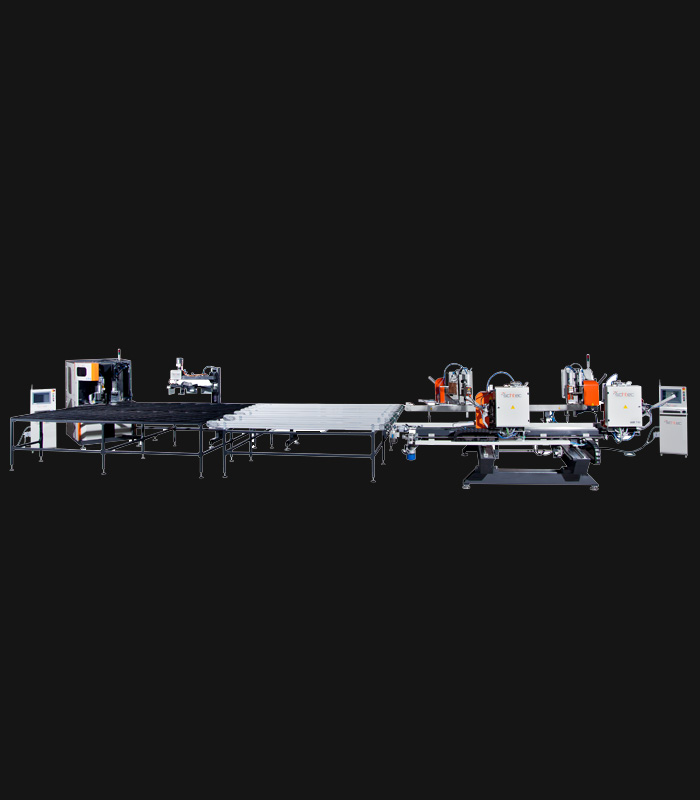

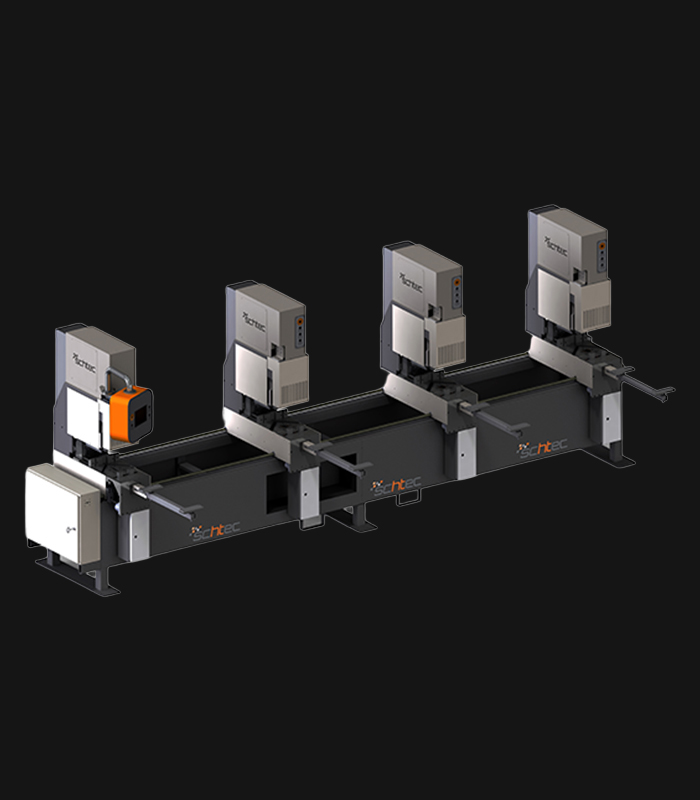

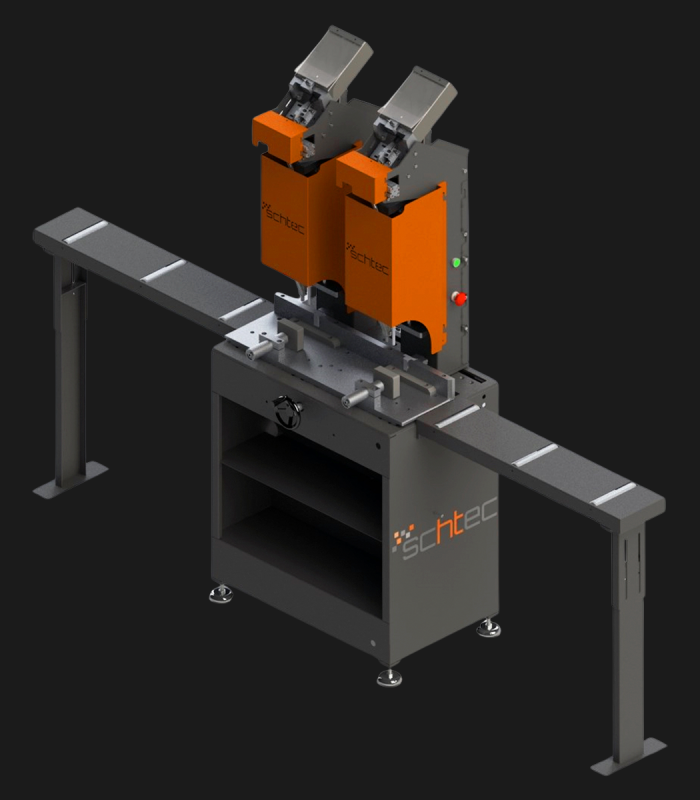

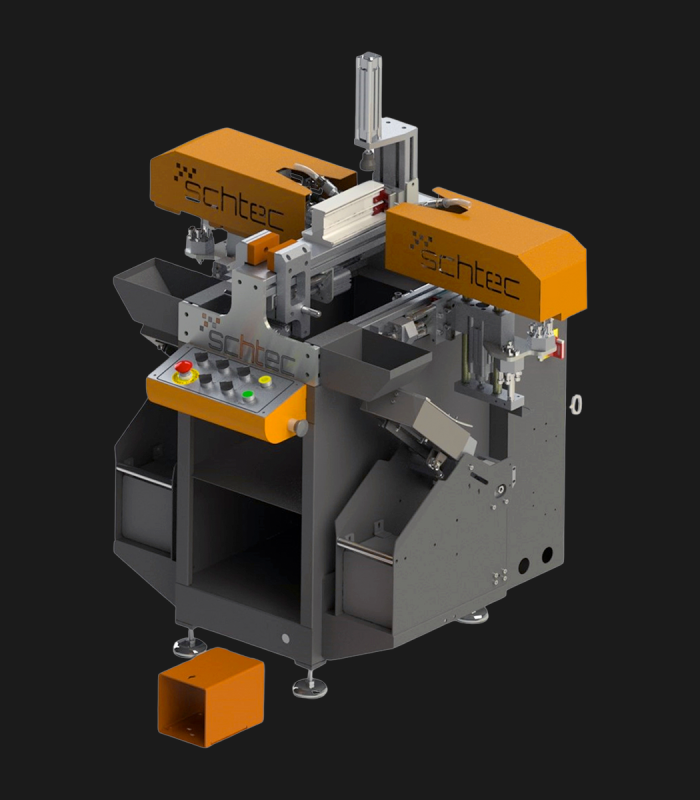

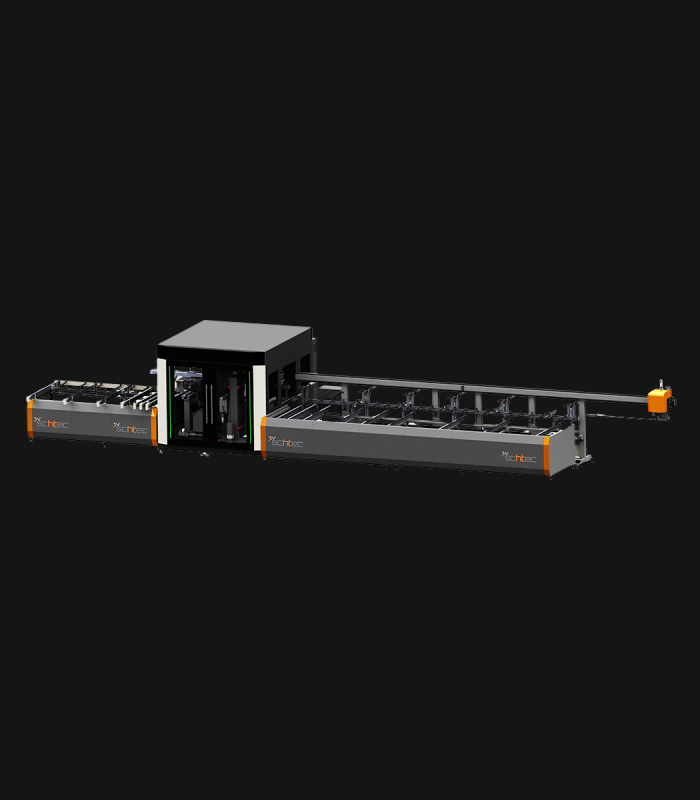

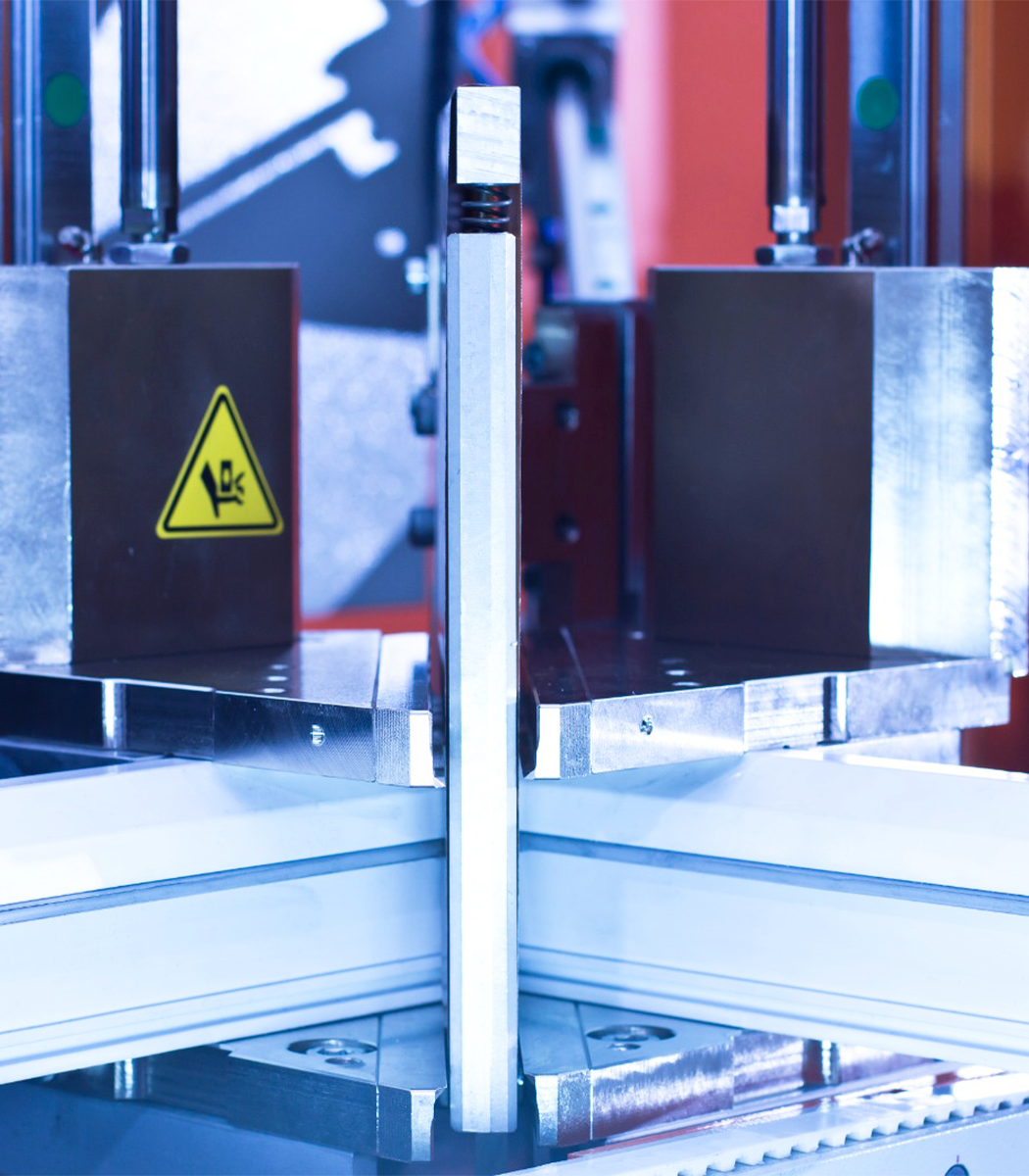

WM 750 Four Head Welding Machine

Schtec WM 750: High-performance servo welder for precise 0.2-2mm 4-corner welds. PID control & fast mold change optimize large-scale production.

WM 750 Technical Specifications

| Power Supply | 400 V, 3ph, 50-60 Hz |

| Power Consumption | 12 kW, 32 A |

| Max. Welding Length | 4.000 mm x 2.600 mm |

| Min. Welding Length | 400 mm x 400 mm |

| Max. Welding Length (with gasket pressing) | 520 mm x 570 mm |

| Max. Profile Height | 180 mm |

| Min. Profile Height | 27 mm |

| Max. Profile Width | 120 mm |

| Air Pressure | 6-8 bar |

| Air Consumption | 70 lt./min. |

| Machine Height | 1.880 mm |

| Machine Length | 5.700 mm |

| Machine Width | 4.200 mm |

| Machine Weight | 2.100 kg |

SKU:

WM-750

Category: Welding Machines

Description

Standard Features

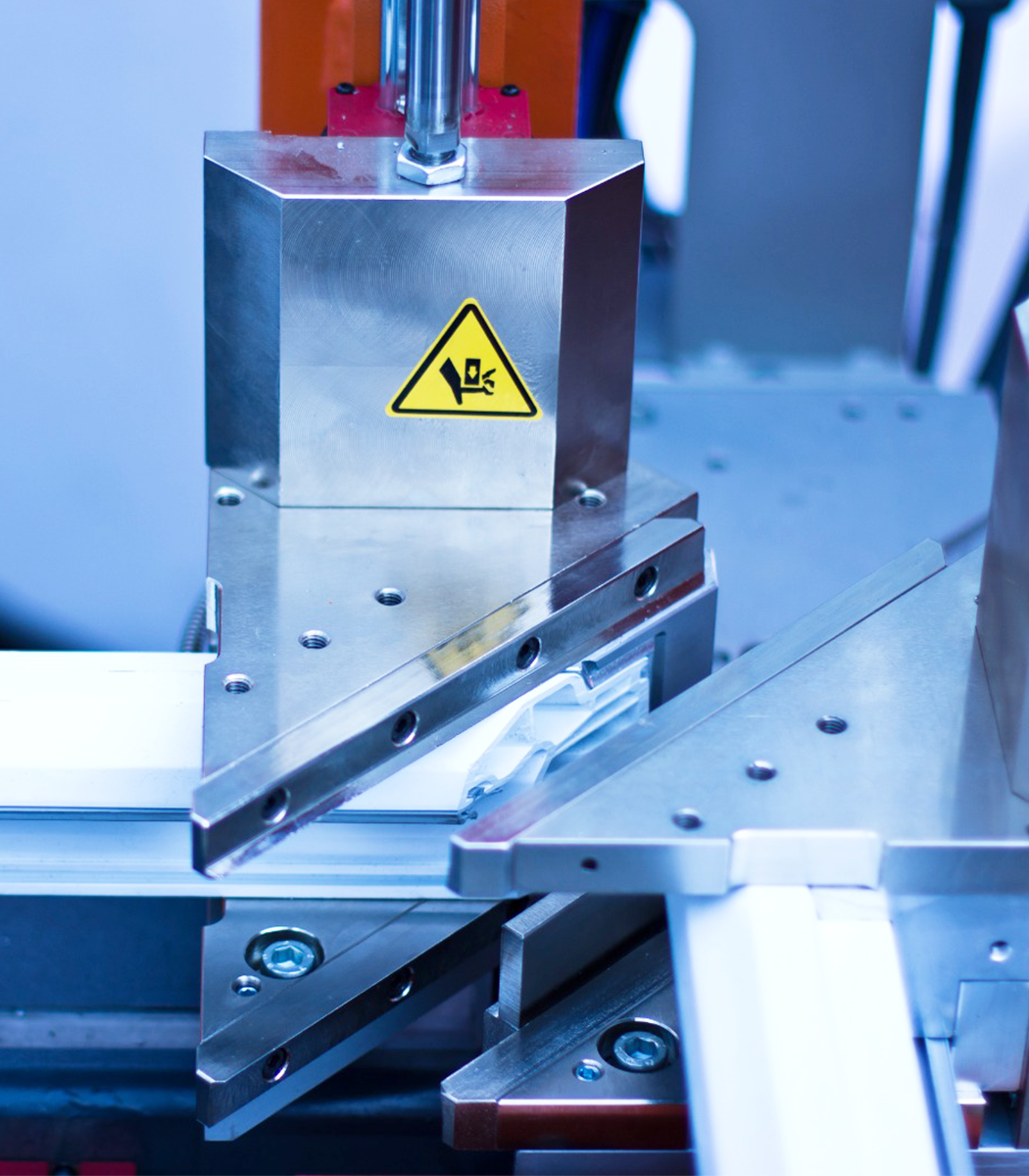

- Welds four corners of PVC profiles simultaneously at 90 °with high sensitivity and strength

- Machine axes are moved by Servo motor system (3 Servo motor controlled axes)

- Specially developed parallel welding technology that improves welding quality and strength

- Internally engineered design for automatic selection of 0.2 and 2 mm welding range

- Beckhoff brand, high performance industrial PC operated by Windows XP Embedded. Fanless motherboard system works between 0°C – 55°C, and it comes with a 15” touch screen display

- Data transfer via ethernet network connection, wireless network connection or USB interface

- Welding parameters are defined by the user for every individual profile(up to 10,000 profiles)

- Welding temperature, melting and welding times can be adjusted individually for each profile type.

- All machine axes are moved by hardened steel ball screw which provides accuracy and durability.

- Depending on the torque values of the servo motors, melting the lengths up to 2 mm and bringing them to the desired size

- PC controlled (PID) heat control system to obtain strong welding results in compliance with standards.

- Summer / winter working mode is automatically selected,so the temperature adjustment is done easily

- Horizontally placed strong mechanical heating plates distribute heat homogeneously without being affected from difficult working conditions.

- Easy and fast change for teflons by specially designed roll up teflon system.

- Easy and fast change for welding moulds

- Works effectively by compressed air supplied to the system

- White or colour profiles can be weld with the same sensitivity

- Central lubrication system minimizes maintenance time

- Reports can be created for daily, weekly, monthly and annual production

- Light barriers and safety equipment confors to CE machine design with full security

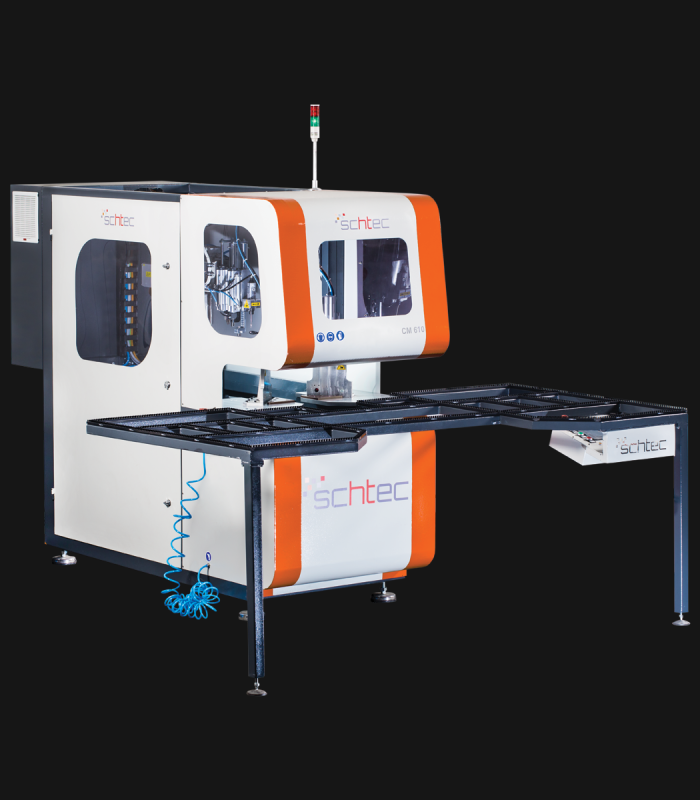

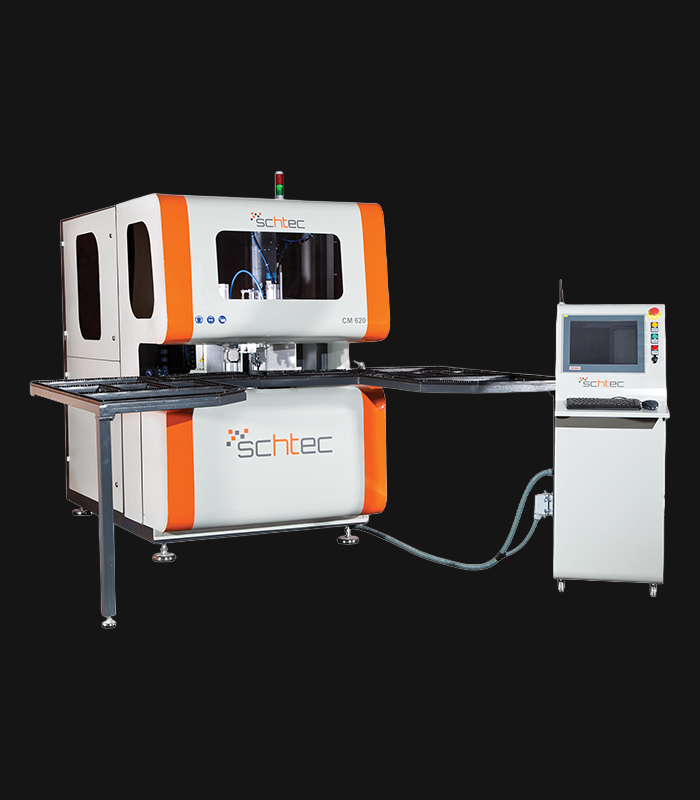

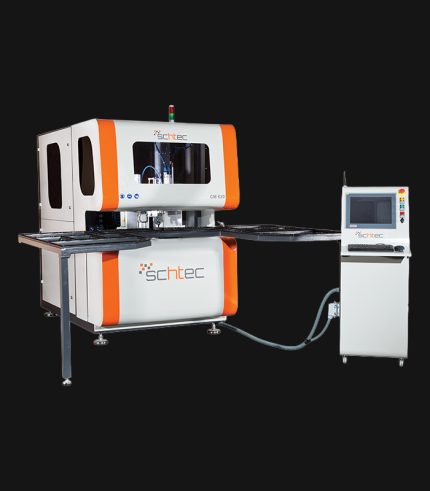

- Stable and accurate data transfer between this machine and the CNC Corner Cleaning Machine via Industrial quality Ethernet connection

- All the error messages and system status can observed on screen by HMI software program developed by the Schtec software department

- Service to the entire automation system,trouble shooting and fault removals can be done by remote connection

Optional Features

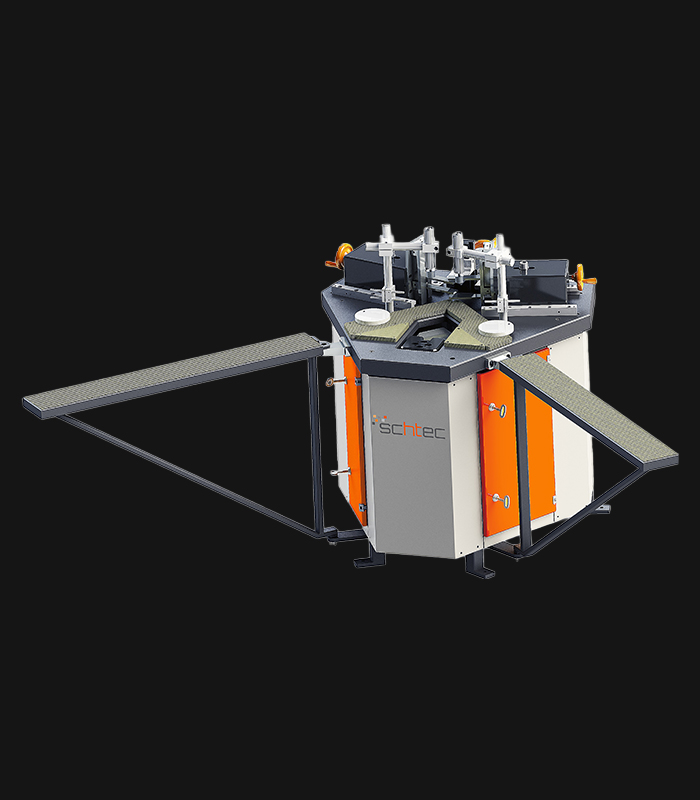

- Gasket pressing system (GR 930)

- Barcode reader (BR 920)

Product Description

The Schtec WM 750 uses servo motor technology to simultaneously weld all four corners with high strength. It features a 3-axis servo system and parallel welding technology for precise welding between 0.2 mm and 2 mm. PID-controlled heat management, automatic summer/winter mode, remote service, and integrated production reporting increase efficiency. Roll-type Teflon and a fast mold change system streamline operations. WM 750 is an ideal high-performance welding solution for large-scale production facilities.

FAQ

Welding Machines

Frequently Asked Questions

Find quick answers to common questions about our Welding Machines.

1. What is the main purpose of a welding machine in PVC manufacturing?

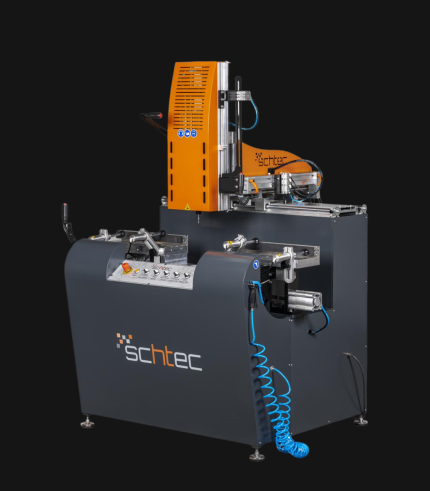

Welding machines like WM 750 Four Head Welding Machine and WD 710 Single Head Welding Machine are used to fuse PVC profile corners by melting material, creating seamless and durable frames. They eliminate the need for mechanical fasteners and ensure air‑ and water‑tight joints. Consistent heat control and pressure maintain structural integrity and appearance over many cycles. In automated lines, welding machines coordinate with cleaning and cutting stations for full process flow.

2. What features should you expect in a high‑performance PVC welding machine?

High‑performance welding machines typically feature servo‑driven axes, parallel welding systems for balanced pressure, PID temperature controllers, and mold parameter storage for multiple profile types. Rapid mold changeover, central lubrication, and Teflon handling systems reduce maintenance downtime. Safety enclosures, light barriers, and efficient air management are also essential. Robust user interfaces and remote diagnostics enhance usability and monitoring.

3. How does the WM 750 Four Head Welding Machine boost productivity?

The WDV 724 is ideal for continuous inline production environments where profiles move through the machine, welding in a flow setup. The WD 720 Double Head Welding Machine is suitable when moderate capacity and flexibility are needed, allowing two corners to be welded simultaneously. Single head machines like WD 710 are good for smaller runs or limited footprint setups. Four‑head machines like WM 740 are preferred for highest throughput in batch production.

4. When would you choose WDV 724 Four Head Inline Welding Machine or WD 720 Double Head Welding Machine?

The WDV 724 is ideal for continuous inline production environments where profiles move through the machine, welding in a flow setup. The WD 720 Double Head Welding Machine is suitable when moderate capacity and flexibility are needed, allowing two corners to be welded simultaneously. Single head machines like WD 710 are good for smaller runs or limited footprint setups. Four‑head machines like WM 740 are preferred for highest throughput in batch production.

5. What maintenance practices ensure durable performance in welding machines?

Clean welding platens, remove residue, and inspect Teflon surfaces regularly to prevent imperfections. Calibrate temperature sensors, PID controls, and servo axes periodically to preserve accuracy. Check pneumatic lines, seals, and air pressure to maintain consistent force during welding. Lubricate motion components and adhere to central lubrication schedules. Monitor error logs, evaluate weld quality, and schedule preventive services to avoid unplanned downtime.