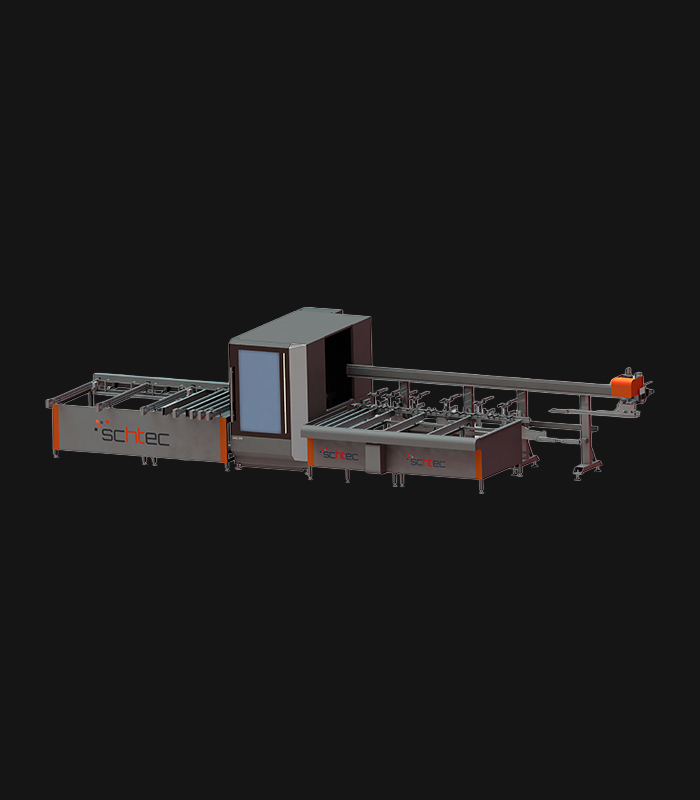

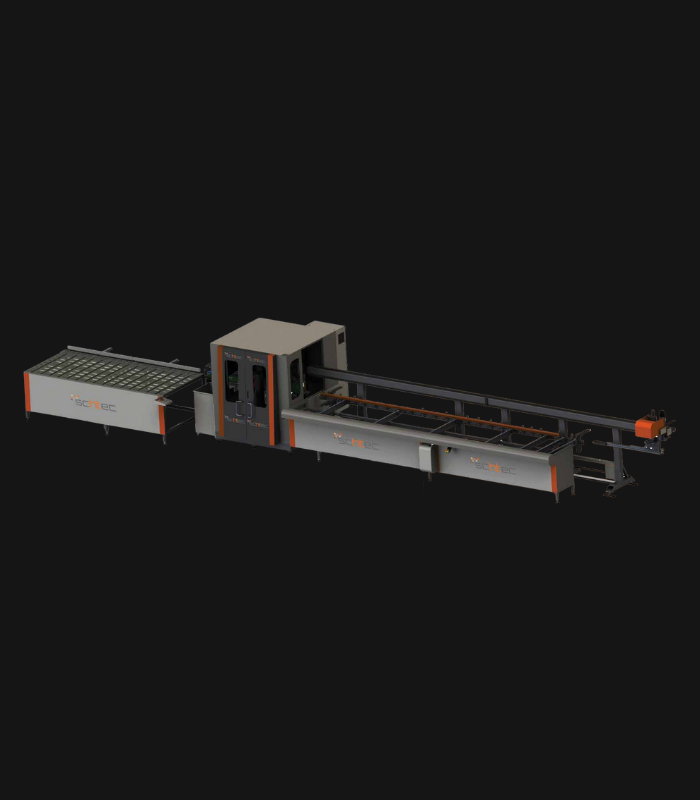

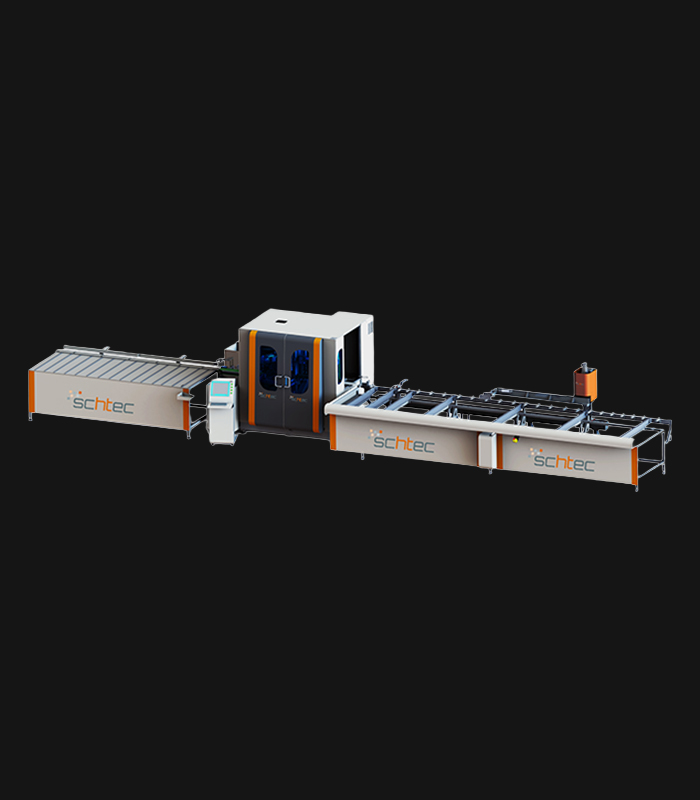

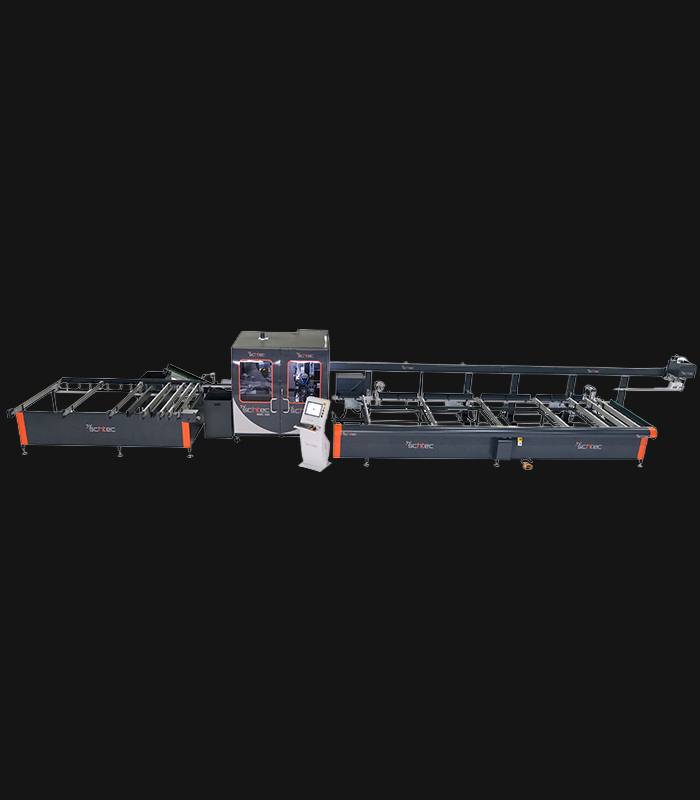

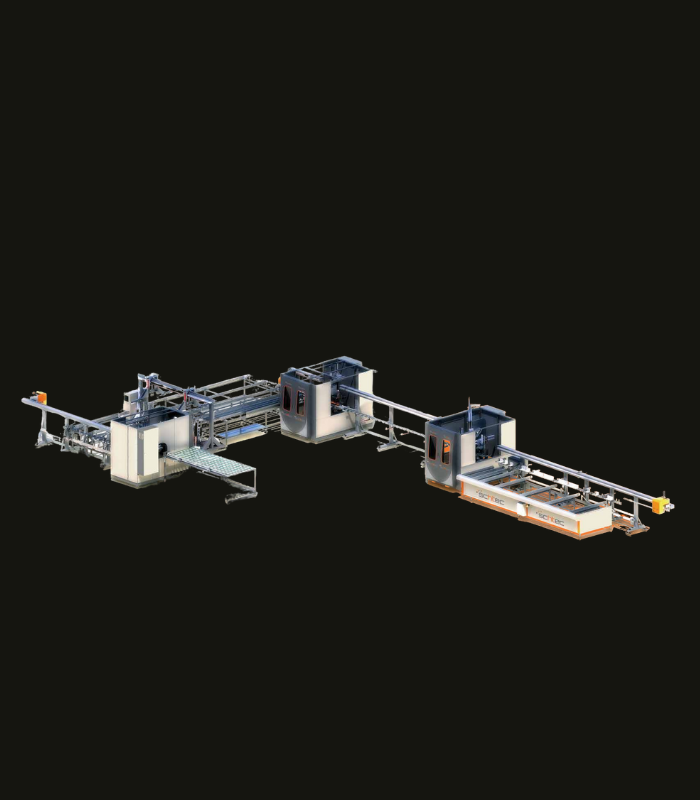

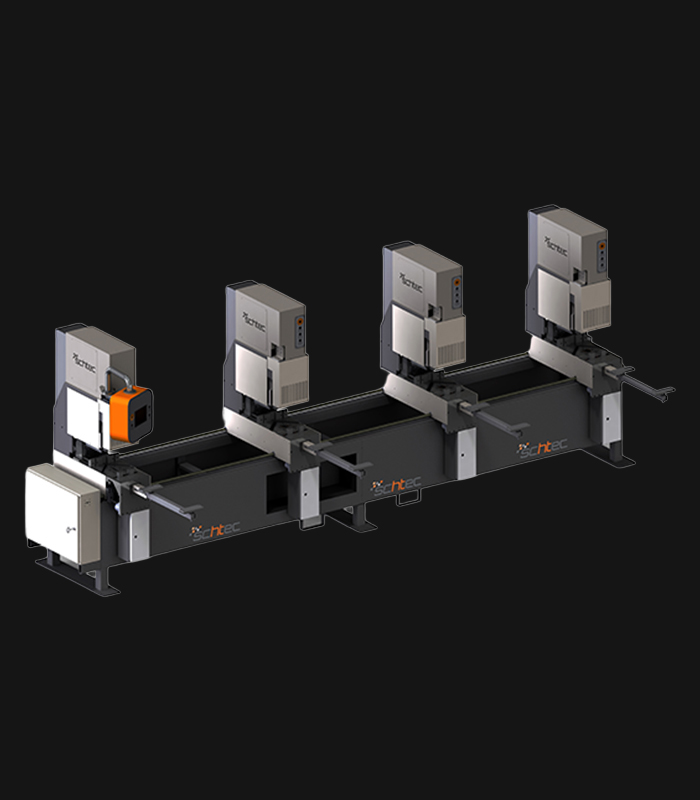

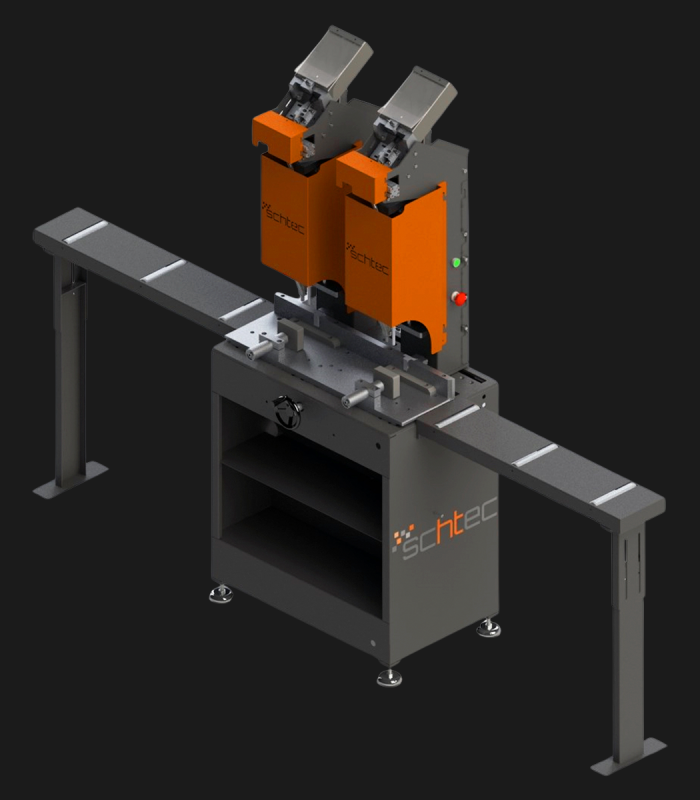

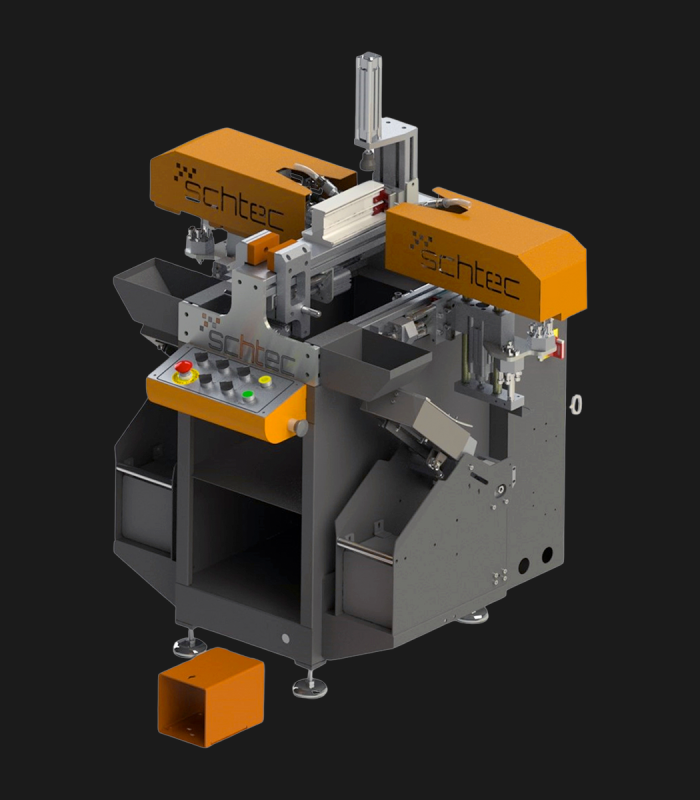

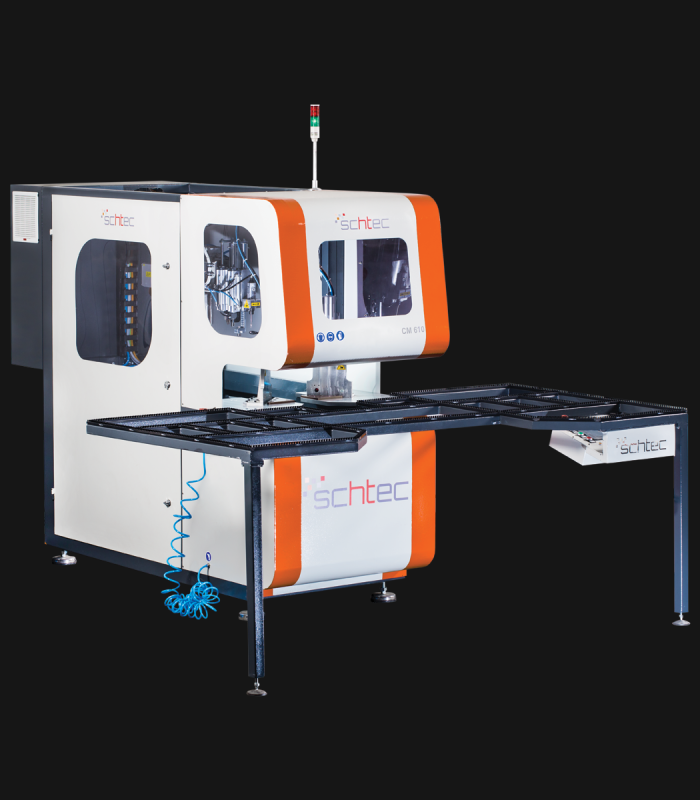

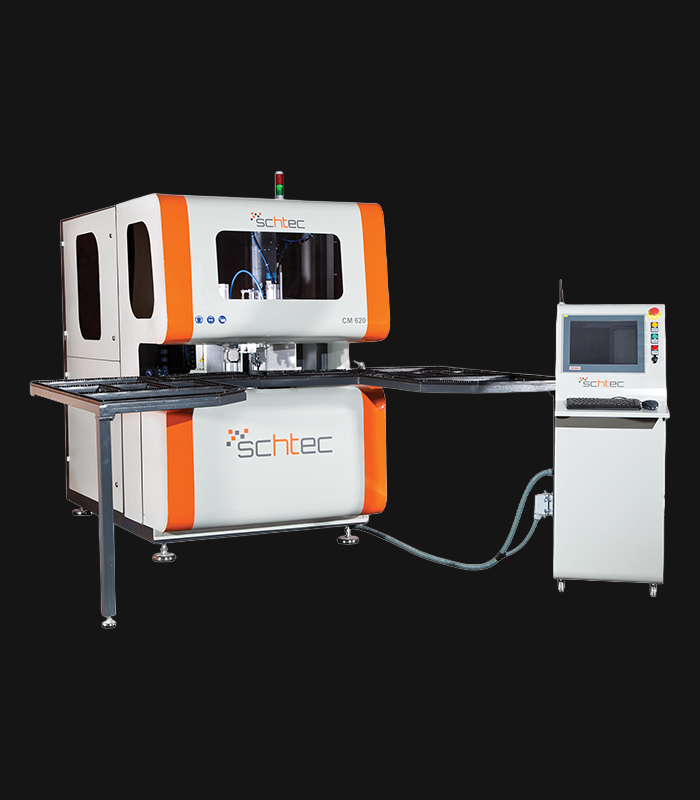

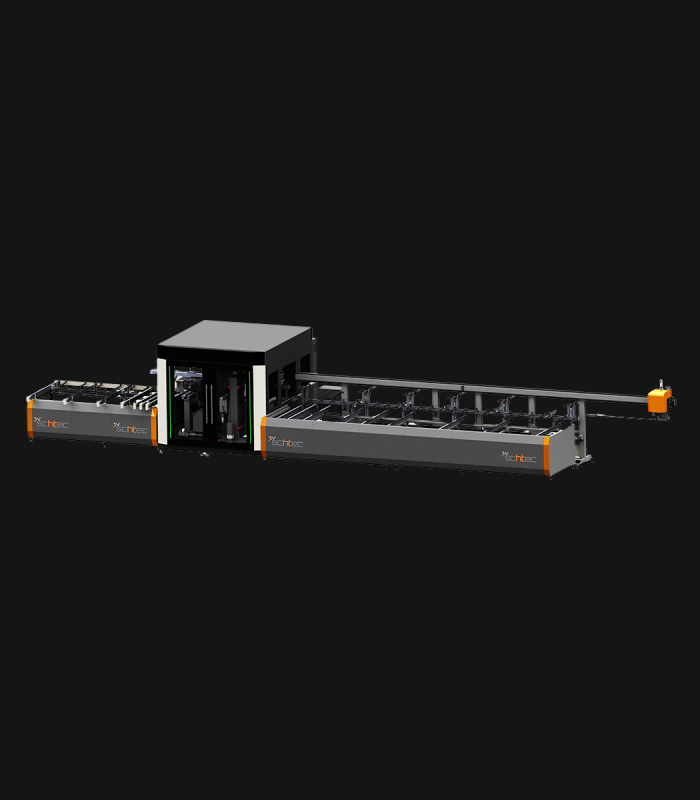

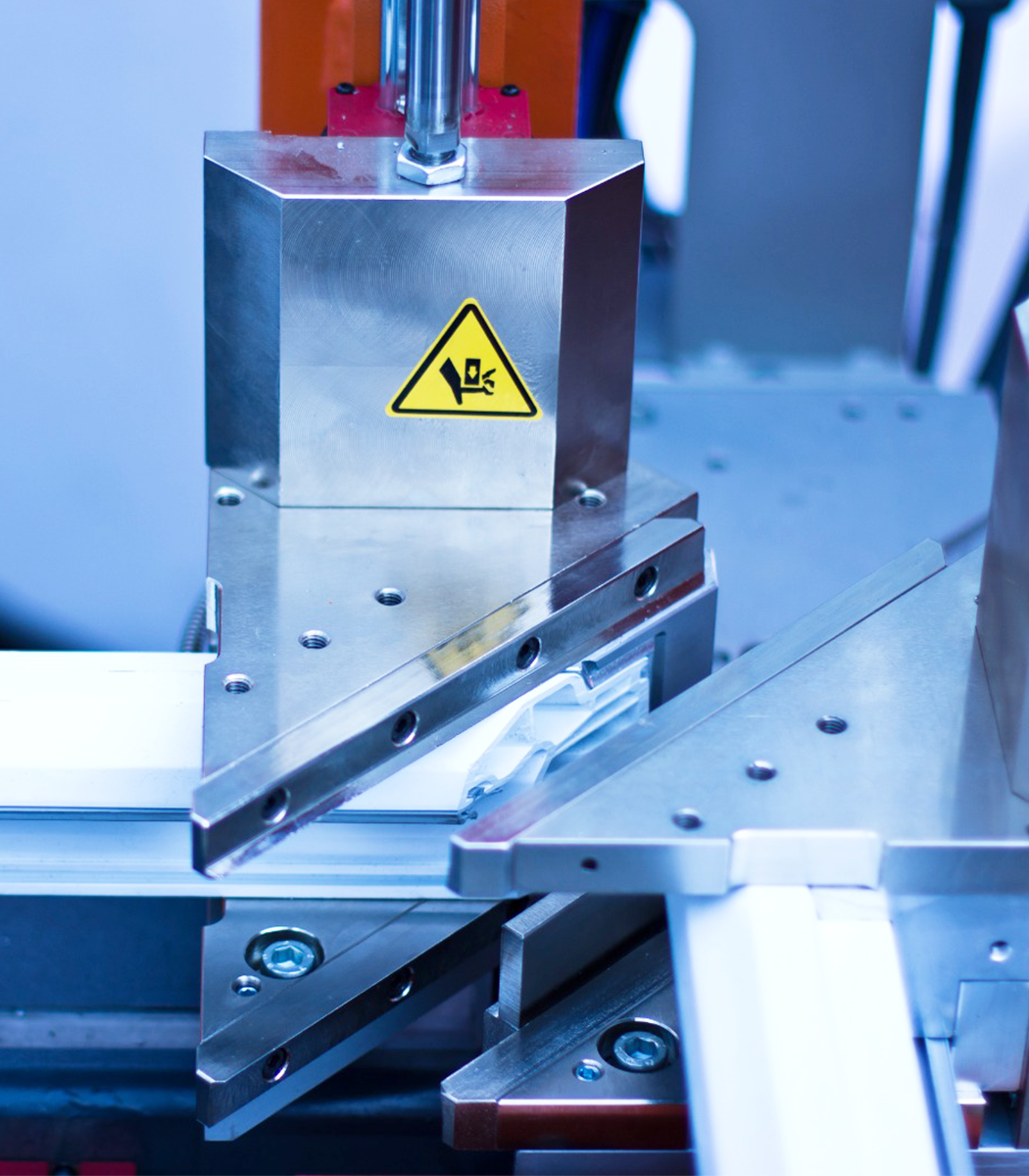

WM 740 Four Head Welding Machine

Schtec WM 740 auto-welds four PVC corners at 90° for high volume production. Features Beckhoff PC, 15” touchscreen, PID heat control, and roll type Teflon system.

WM 740 Technical Specifications

| Power Supply | 400 V, 3ph, 50-60 Hz |

| Power Consumption | 11.5 kW, 28.75 A |

| Max. Welding Length | 4.000 mm x 2.600 mm |

| Min. Welding Length | 450 mm x 450 mm |

| Min. Welding Length (with gasket pressing) | 520 mm x 570 mm |

| Max. Profile Height | 180 mm |

| Min. Profile Height | 27 mm |

| Max. Profile Width | 120 mm |

| Air Pressure | 6-8 bar |

| Air Consumption | 70 lt./min. |

| Machine Height | 1.880 mm |

| Machine Length | 5.700 mm |

| Machine Width | 4.200 mm |

| Machine Weight | 1.920 kg |

Standard Features

- Welds four corners of PVC profiles simultaneously at 90 °with high sensitivity and strength

- Beckhoff brand, high performance industrial PC operated by Windows XP Embedded. Fanless motherboard system works between 0°C – 55°C, and it comes with a 15” touch screen display

- Data transfer via ethernet network connection, wireless network connection or USB interface

- Welding parameters are defined by the user for every individual profile(up to 10,000 profiles)

- Welding temperature, melting and welding times can be adjusted individually for each profile type.

- All machine axes are moved by hardened steel ball screw which provides accuracy and durability.

- PC controlled (PID) heat control system to obtain strong welding results in compliance with standards.

- Summer / winter working mode is automatically selected,so the temperature adjustment is done easily

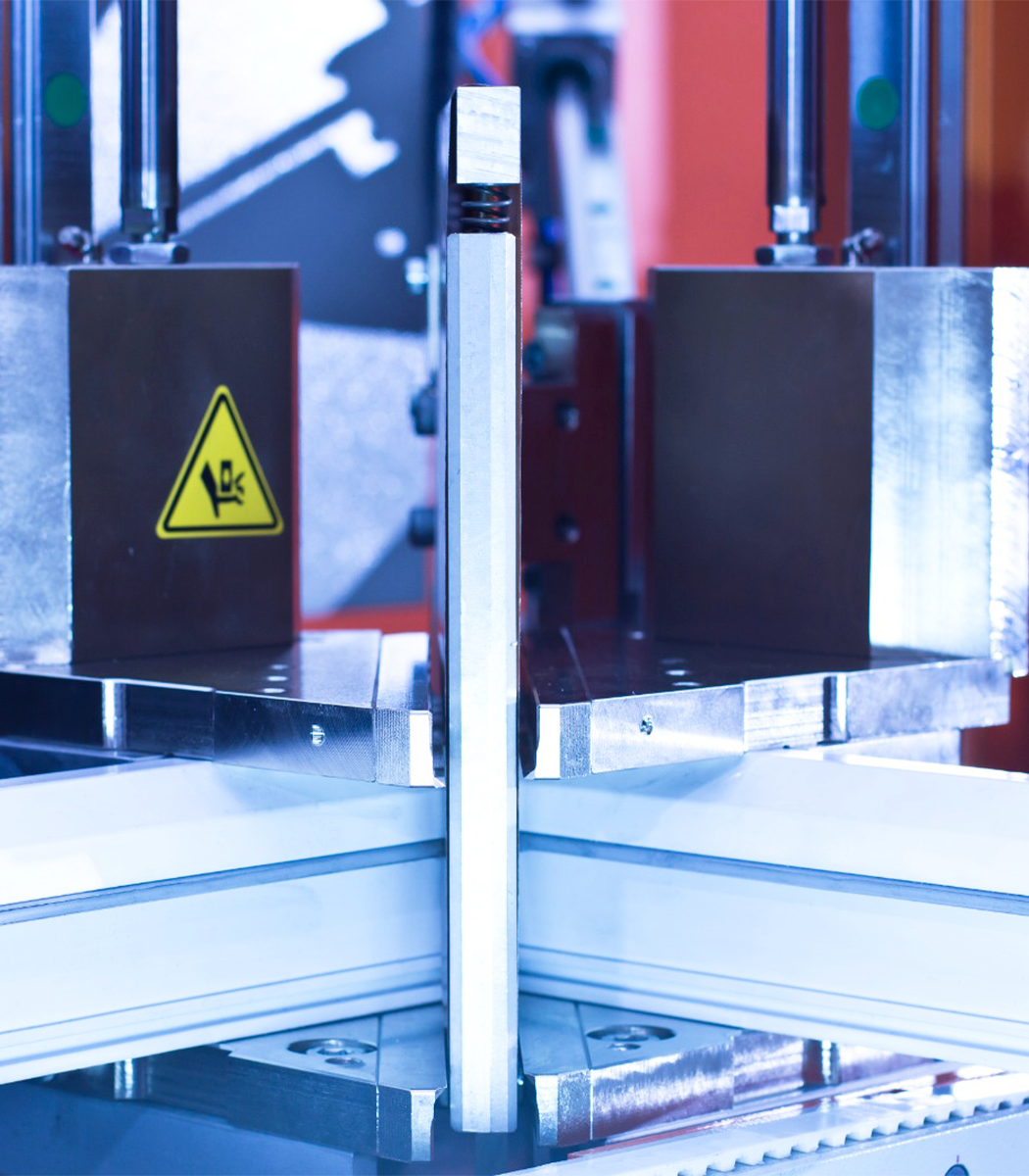

- Horizontally placed strong mechanical heating plates distribute heat homogeneously without being affected from difficult working conditions.

- Easy and fast change for teflons by specially designed roll up teflon system.

- Easy and fast change for welding moulds

- Works effectively by compressed air supplied to the system

- White or colour profiles can be weld with the same sensitivity

- Central lubrication system minimizes maintenance time

- Reports can be created for daily, weekly, monthly and annual production

- Light barriers and safety equipment confors to CE machine design with full security

- Stable and accurate data transfer between this machine and the CNC corner cleaning machine via Industrial quality Ethernet connection

- All the error messages and system status can observed on screen by HMI software program developed by the Schtec software department

- Service to the entire automation system,trouble shooting and fault removals can be done by remote connection

Optional Features

- Gasket pressing system (GR 930)

- Barcode reader (BR 920)

Product Description

The Schtec WM 740 automatically welds all four corners of PVC window and door profiles at 90° angles. Fully automated, it delivers high efficiency for large-scale production. It includes a Beckhoff industrial PC with a 15” touchscreen, PID heat control for stable seasonal performance, a 10,000-profile memory bank, and wireless/Ethernet data integration. The roll-type Teflon change system and centralized lubrication reduce maintenance time. WM 740 is designed for speed, precision, and safety in high-volume manufacturing.

Frequently Asked Questions

Find quick answers to common questions about our Welding Machines.