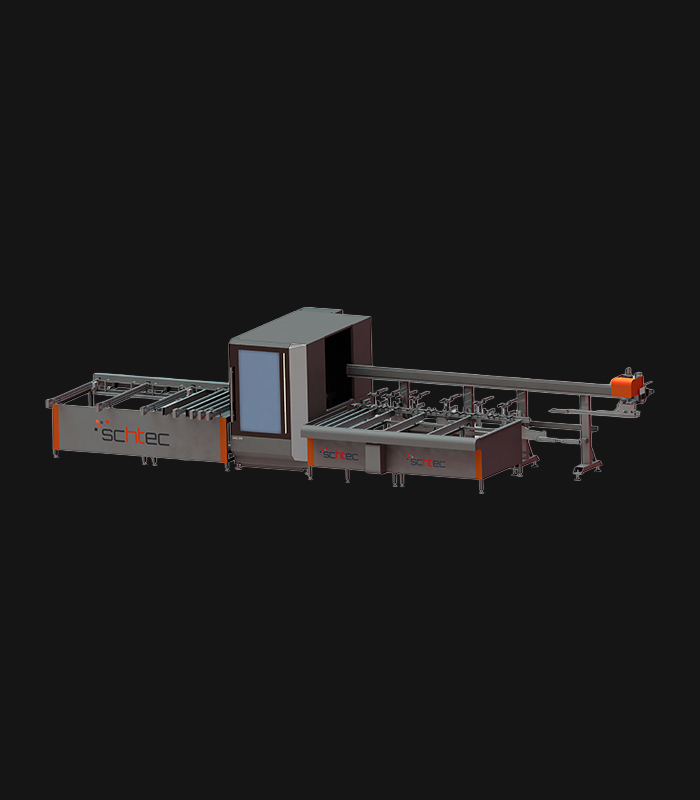

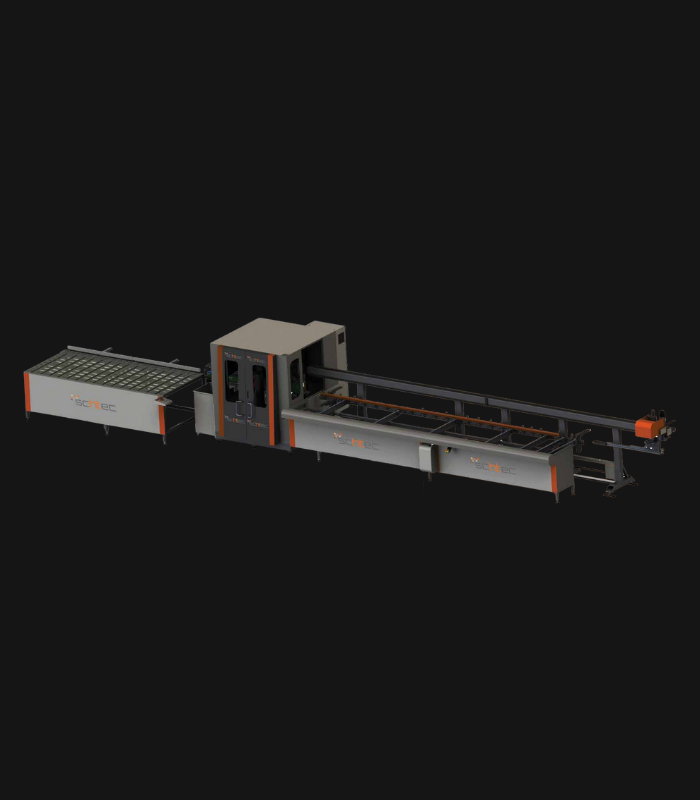

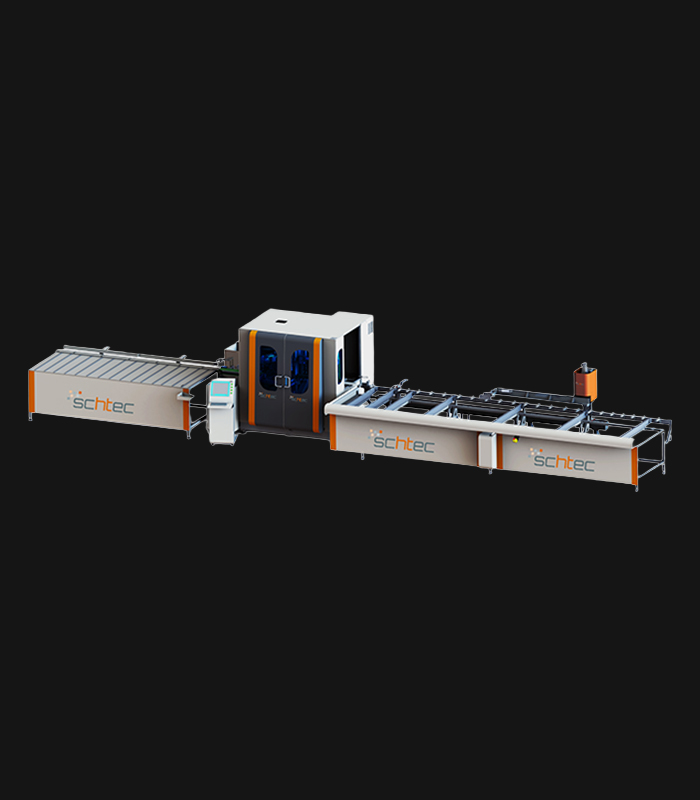

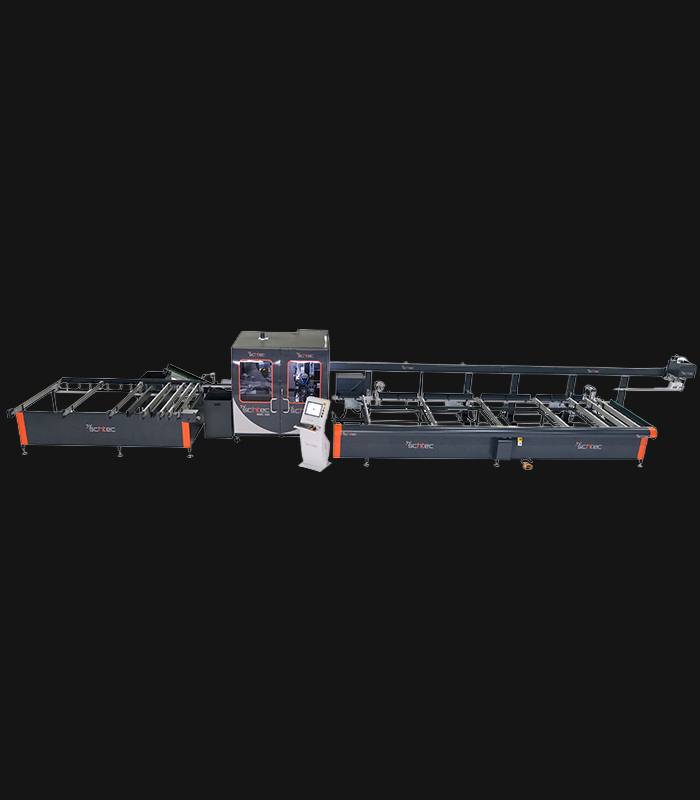

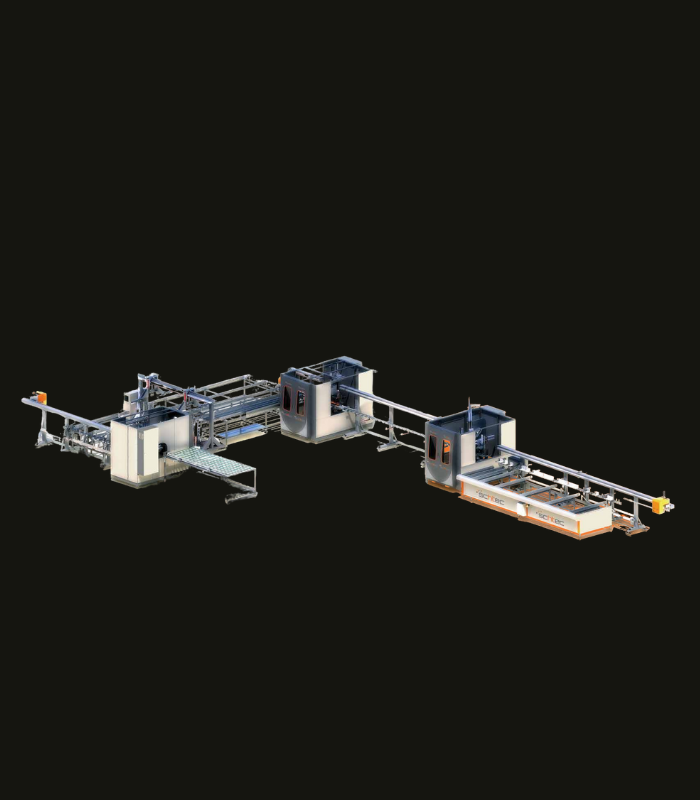

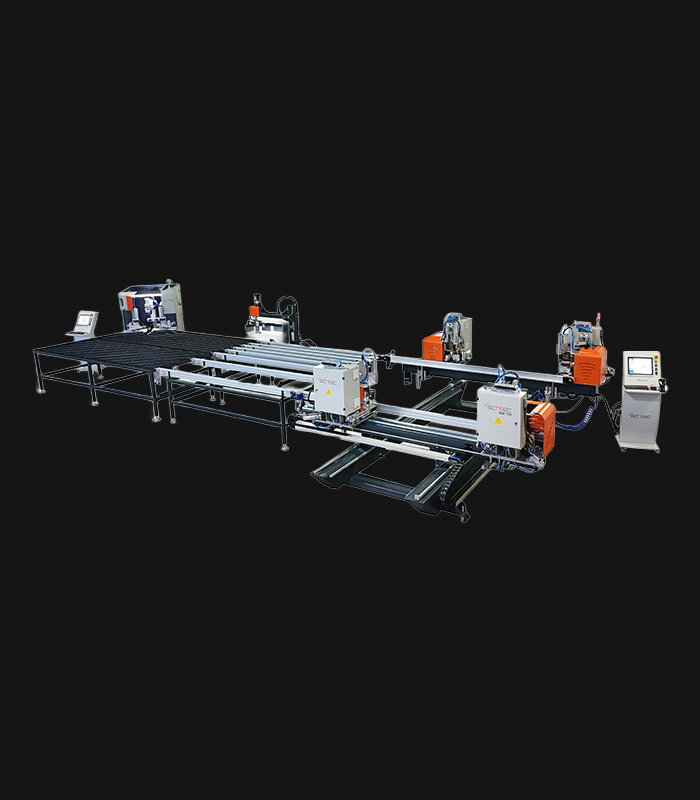

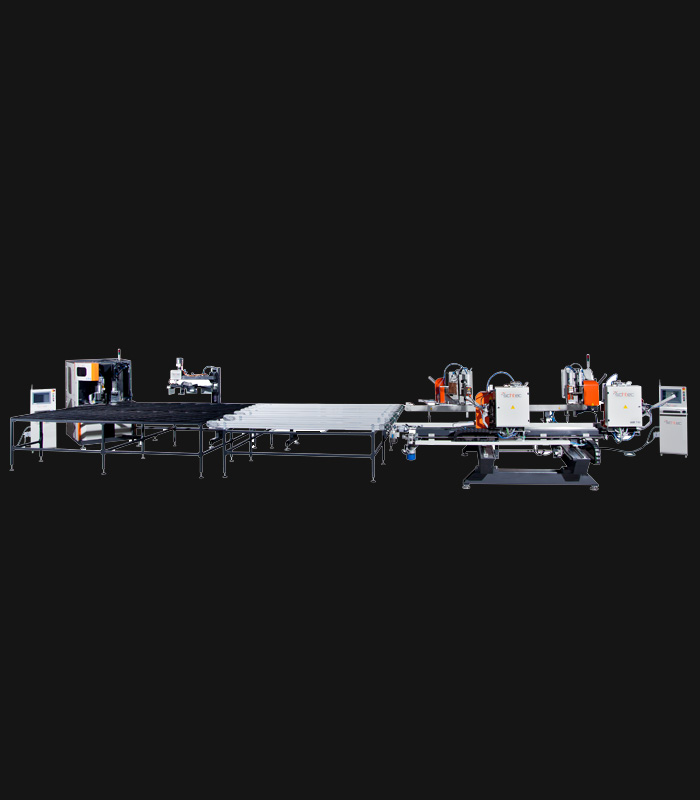

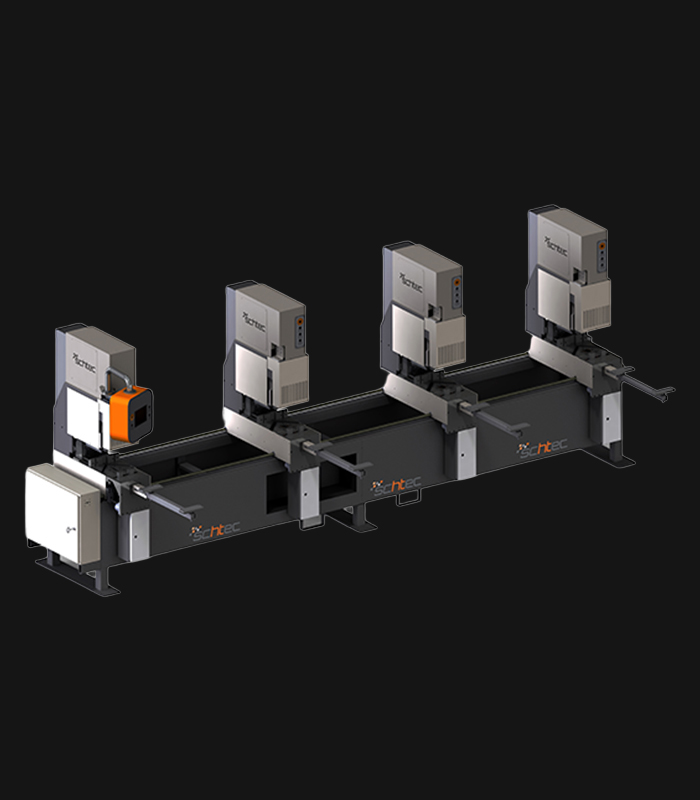

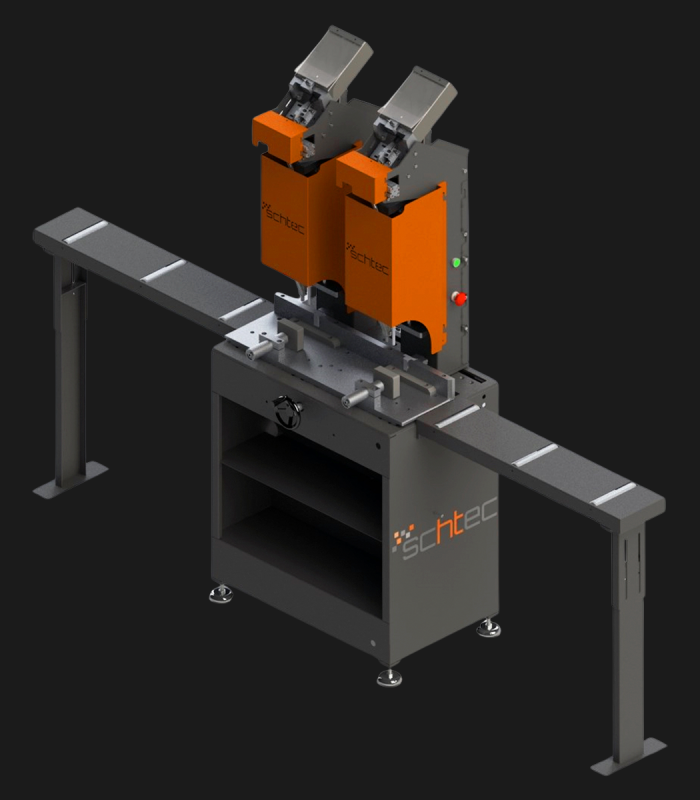

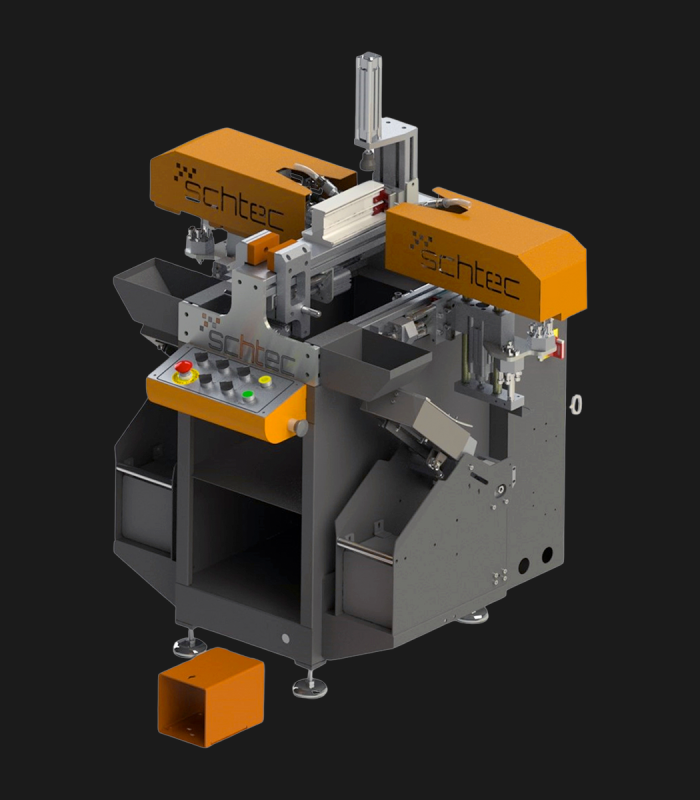

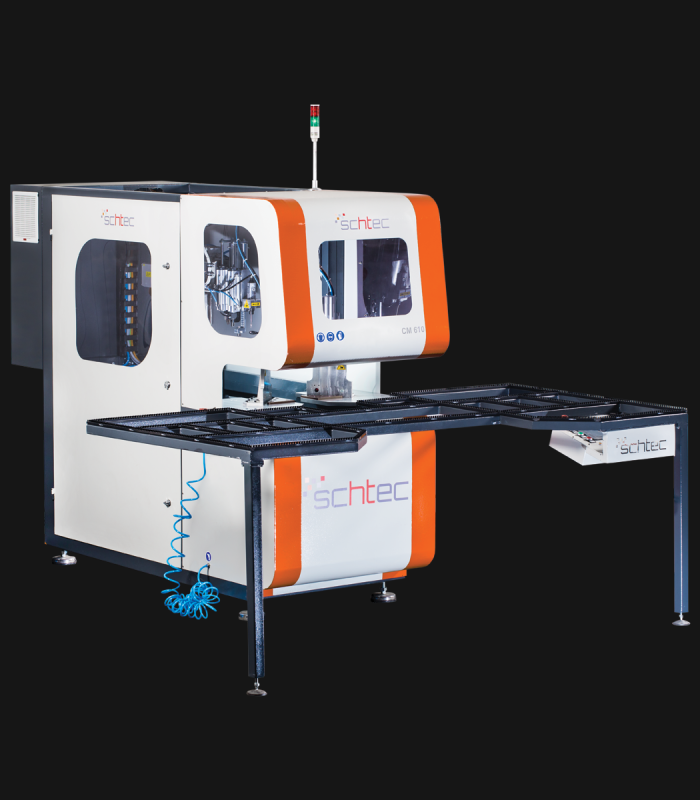

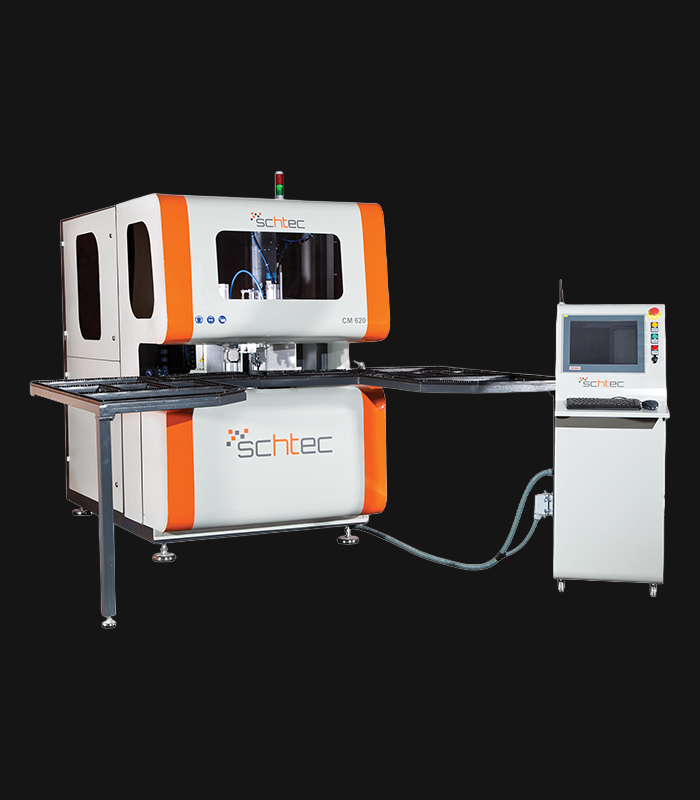

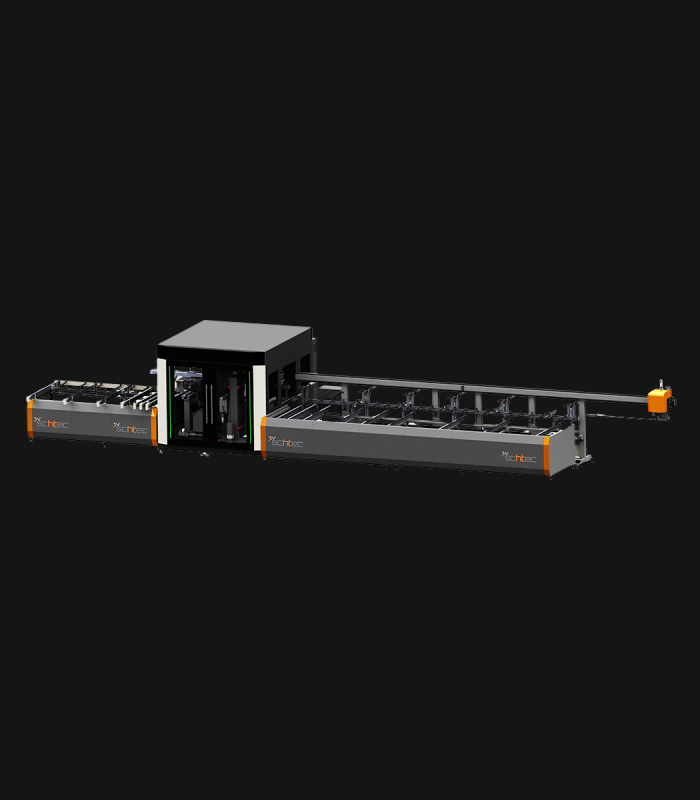

SD 140 Automatic Double Head PVC & Aluminium Cutting Machine

SCHTEC SD 140 Automatic Double Head Cutting Machine: High-precision cutting for PVC and aluminum profiles. Cutting angles 20°–160°, 500 mm blades, 4.5 m cutting capacity, barcode integration, and optional cooling system deliver maximum efficiency and safety in industrial production.

SD 140 Technical Specifications

| Power Supply | 400 V, 3 Ph, 50-60 Hz |

| Total Power | 8.5 kW / 21.25 A |

| Power Output of Each Motor | 2.2 kW |

| Spindle Speed | 3,000 rpm |

| Max. Cutting Length | 4,500 mm (Up to 6,500 mm with software support) |

| Min. Cutting Length | 500 mm (Up to 450 mm with software support) |

| Air Pressure | 6-8 bar |

| Air Consumption | 50 l/min |

| Machine Height | 1,800 mm |

| Machine Length | 5,850 mm |

| Machine Width | 1,595 mm |

| Machine Weight | 1,000 kg |

Standard Features

- High precision cutting of PVC and Aluminium profiles

- Strong construction, lineer rail and sliding-bearing system for precise length and angle.

- The saw heads tilt automatically for 45° and 90° cutting and easy manual fixation for Intermediate angles

- Two pieces of 80mm. dropper sash profiles can be cut by means of 500 mm saw blade in the same time

- Easily adjustable blade cutting speed

- Data transfer via local network connection or USB port

- Profile support system to balance of the work piece

- Ergonomic design for ease of use

- Self-closing protective hoods for work safety

- Vertical and horizontal pneumatic profile clamping system for the best fixation

- The left head of the machine is fixed and the right head moves on the chassis

Optional Features

- Barcode printer system (LS 930)

- Cooling system to cut Aluminium profiles (GC 265) and hydro-pneumatic system

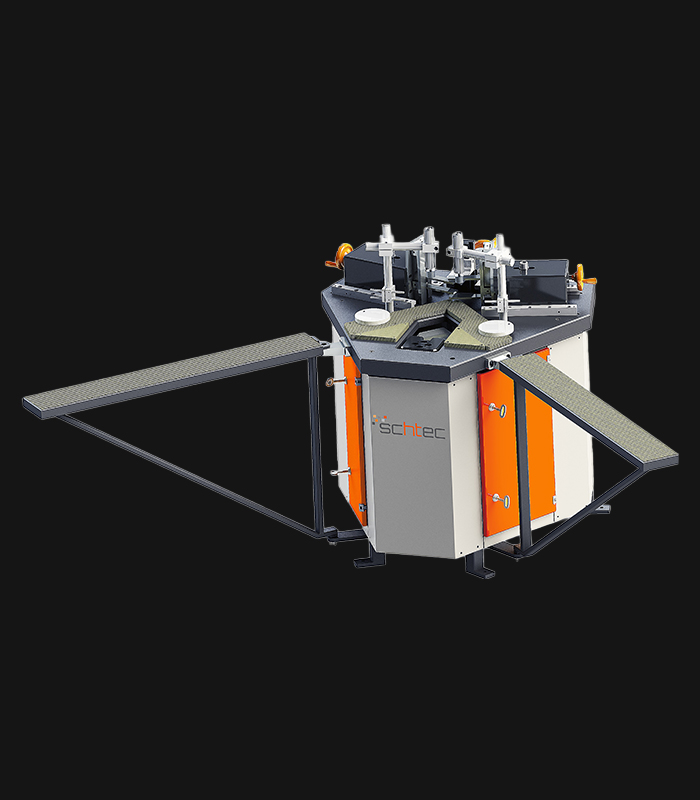

- Automatic Aluminium wedge cutting system (MA270)

Product Description

The SCHTEC SD 140 is a versatile automatic double-head machine developed for the precise cutting of PVC and aluminum profiles. Its 500 mm saw blade enables simultaneous cutting of double-wing profiles with 80 mm drip edges. Featuring a linear rail system, a rigid frame, and horizontal-vertical pressure pistons, it delivers smooth and long-lasting operations. It supports fixed angles between 45° and 90° as well as manual intermediate angles. With a secure structure and 8.5 kW motor power, the SD 140 ensures maximum control and efficiency in production processes.

Frequently Asked Questions

Find quick answers to common questions about our PVC Cutting Machines.