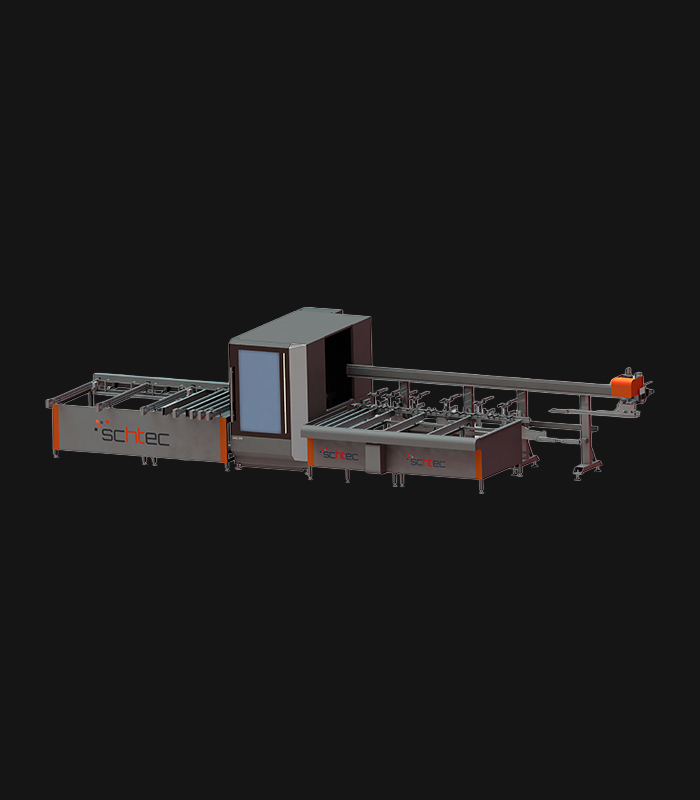

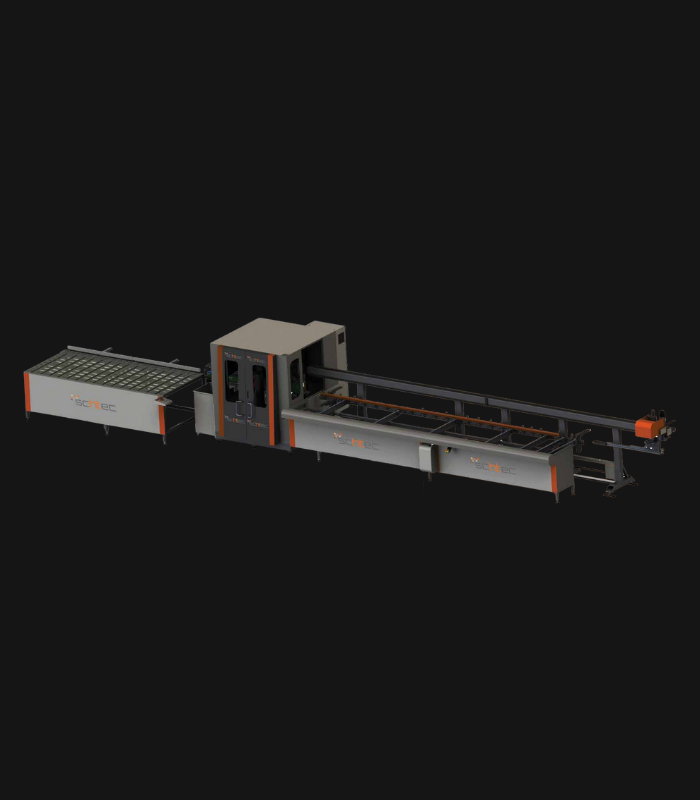

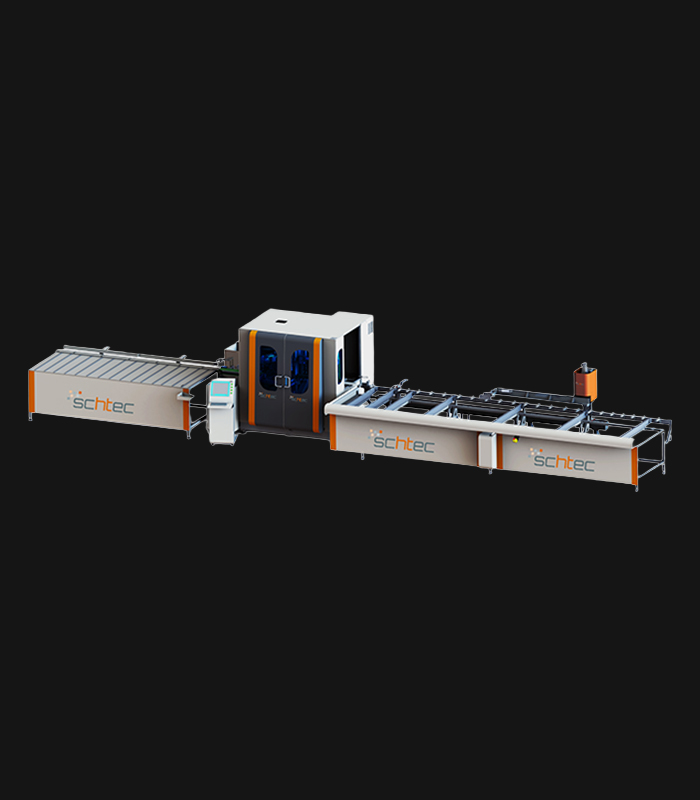

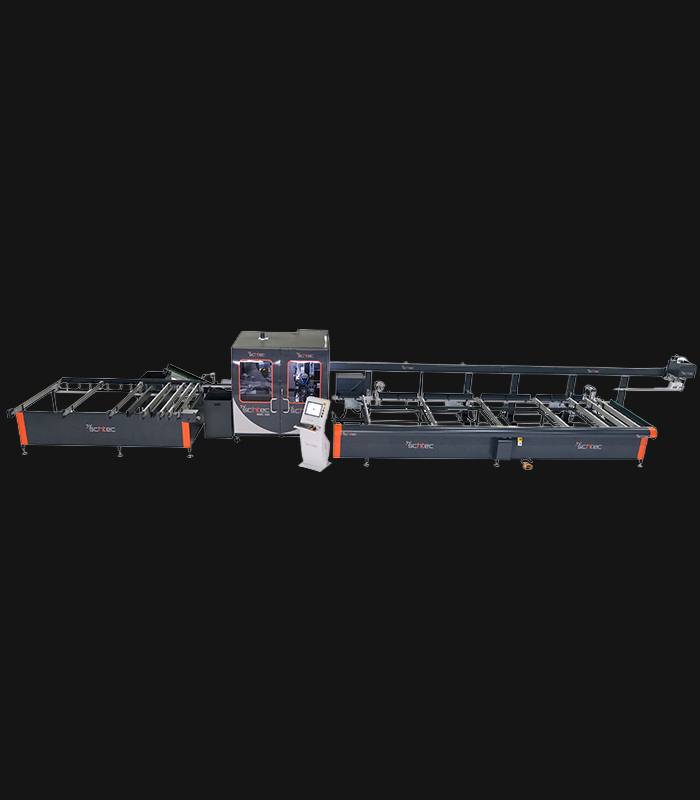

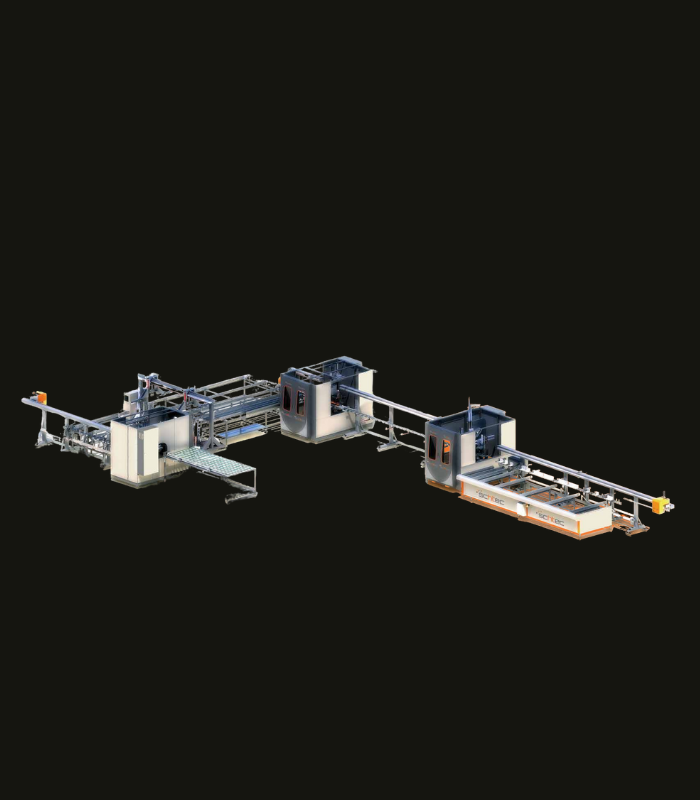

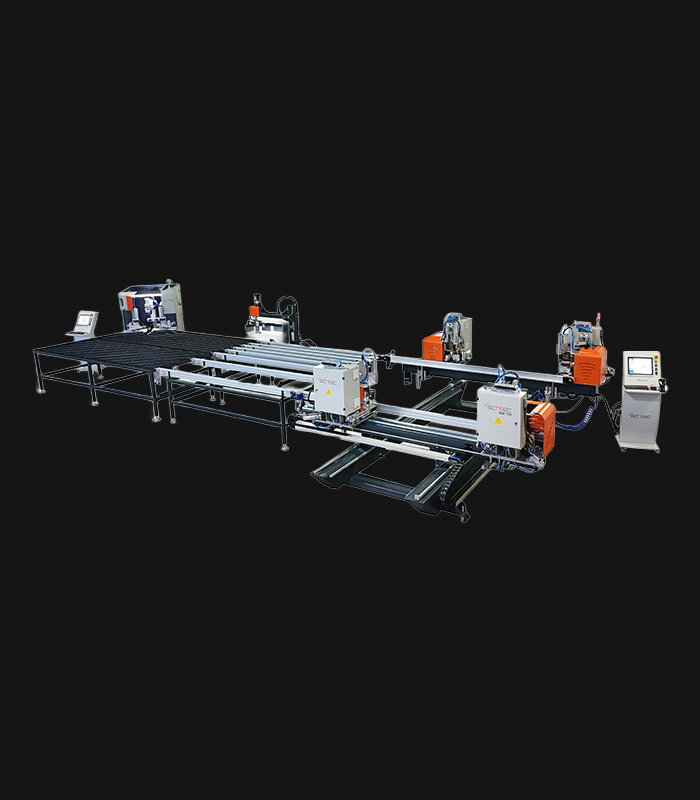

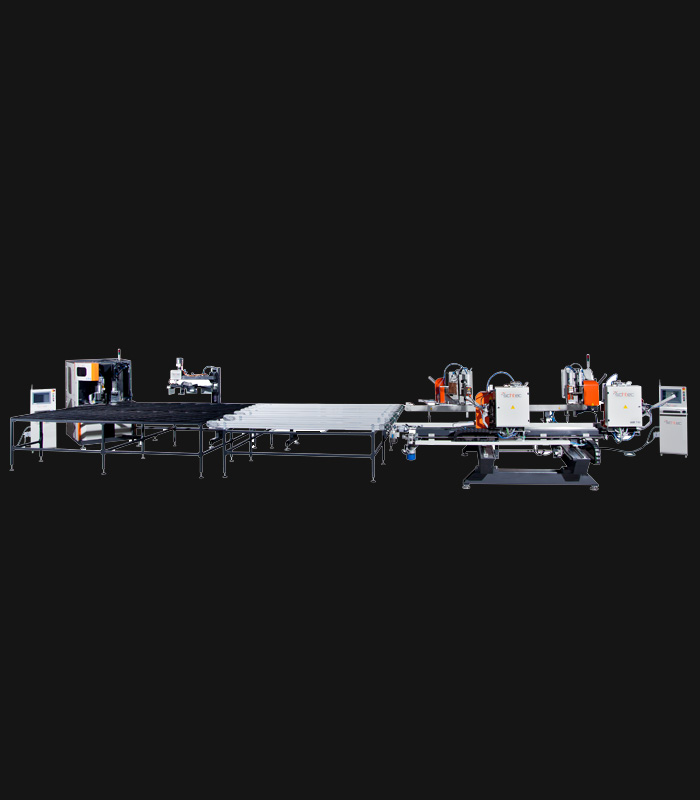

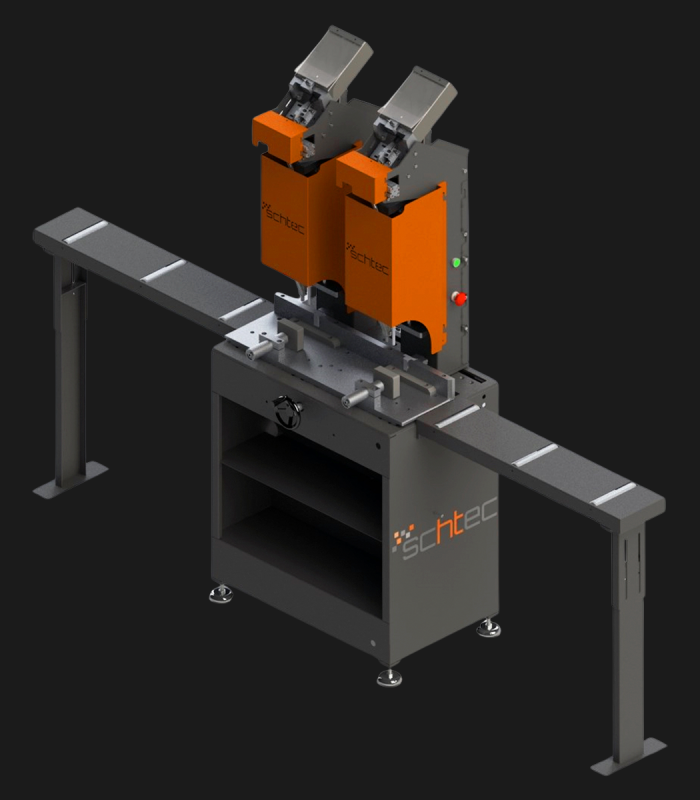

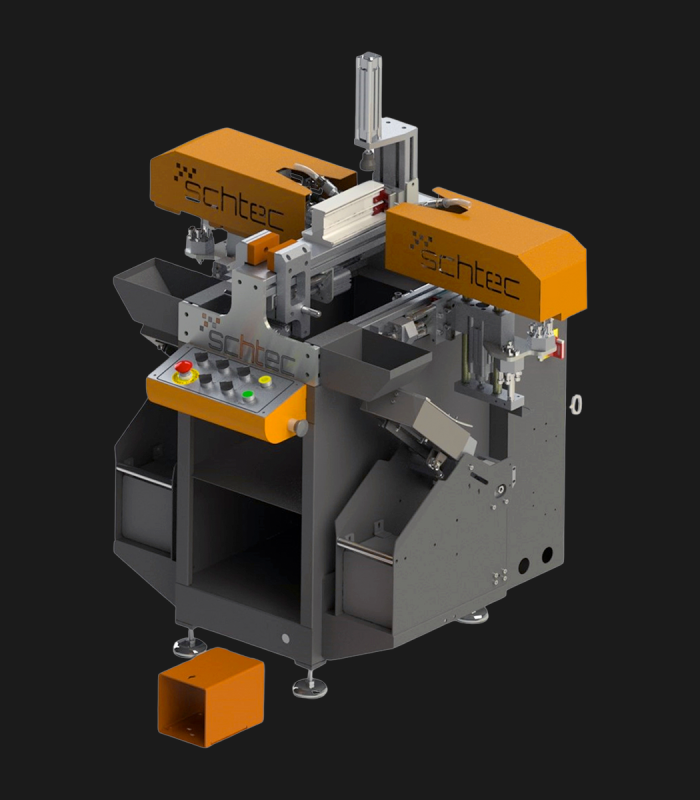

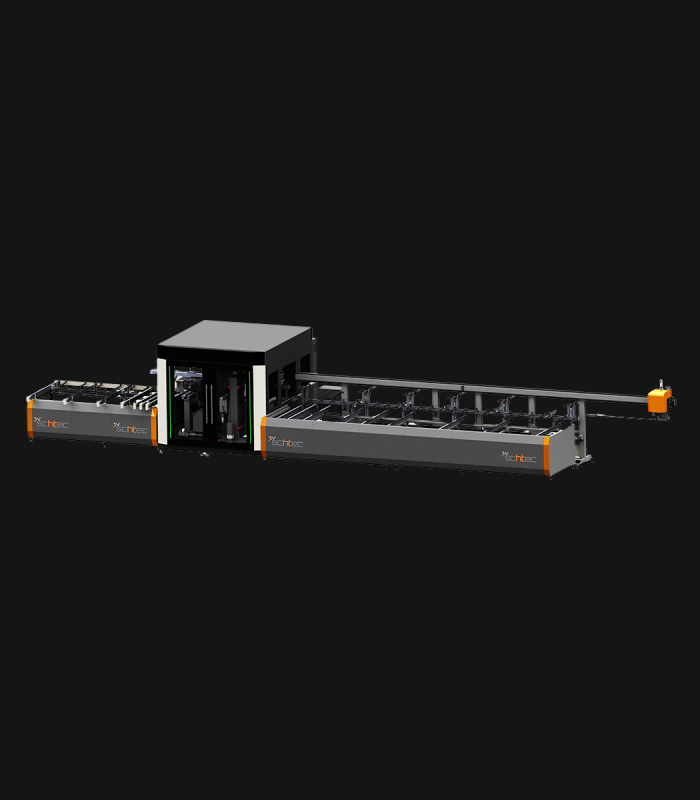

SA 280 Sash Assembly Station

Schtec SA 280 automatically installs tilt-and-turn PVC accessories with high precision. Mold-less, auto centering, laser screwing. Boosts efficiency.

SA 280 Technical Specifications

| Voltage | 380 V, 3 Ph, 50-60 Hz |

| Total Power | 3 kW |

| Air Pressure | 6–8 bar |

| Air Consumption | 245 lt./min |

| Minimum Window Width | 330 mm |

| Maximum Window Width | 2,500 mm |

| Machine Height | 2,030 mm |

| Machine Length | 3,255 mm |

| Machine Width | 2,010 mm |

| Machine Weight | 615 kg |

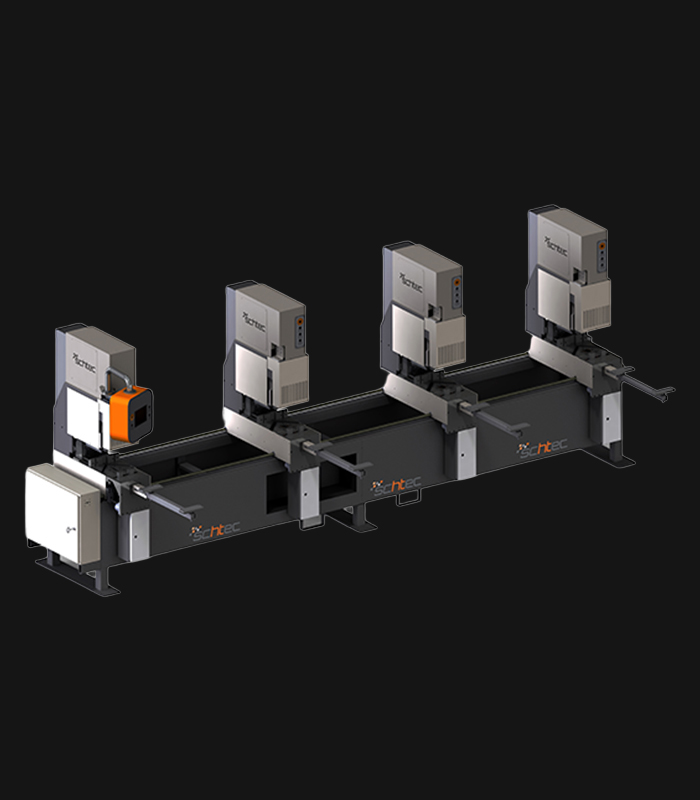

Standard Features

Different series of different sizes of doors / windows, all used tilt and turn accessories on the surface of the frame without using the meter and pen, adjustable to different profiles, without the need to form and pattern, enables serial and high-quality installation in a standard way

- Sash assembly table

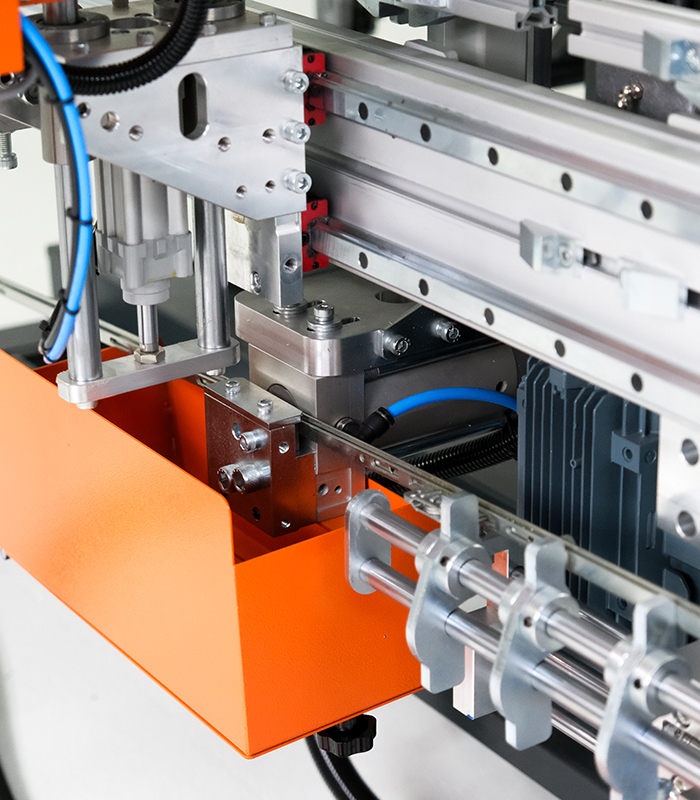

- Automatic centering system of the sash

- Automatic measurement system for espagnolette and scissors

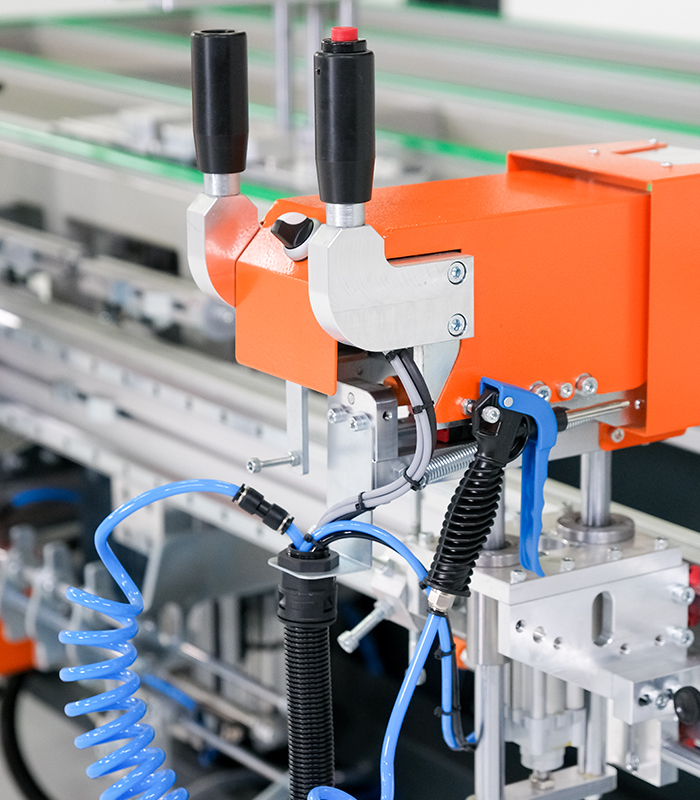

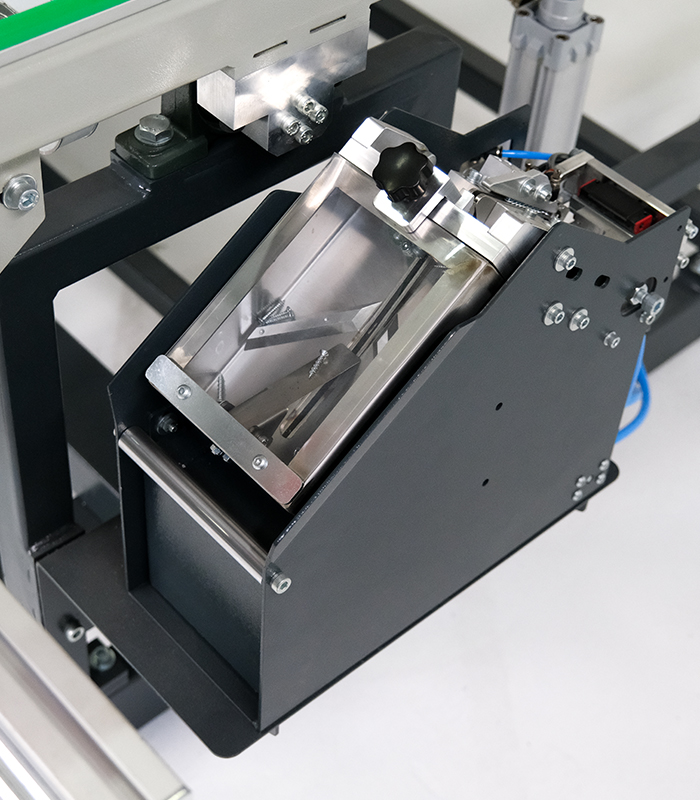

- Cutting punch for espagnolette and scissors

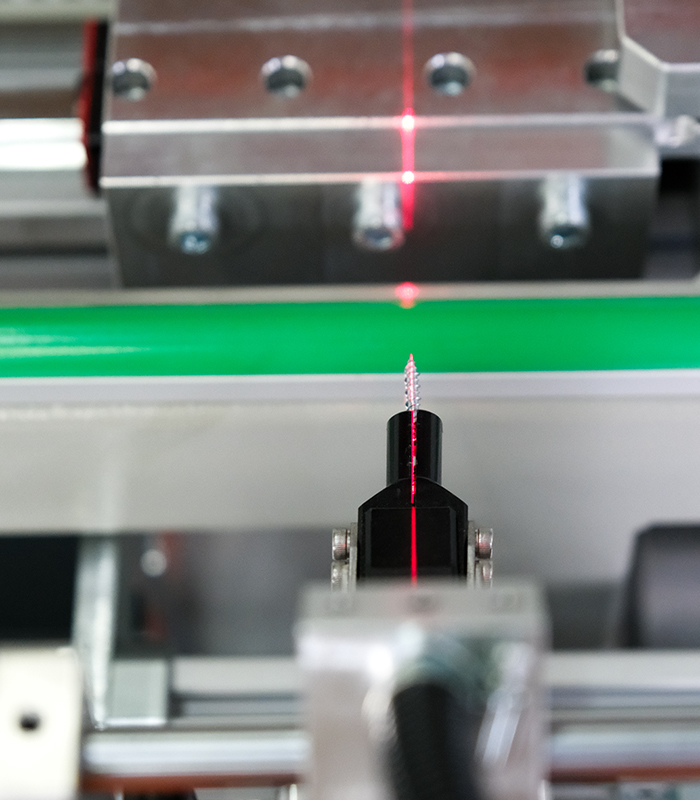

- The automatic screwdriver, automatic screw feeding

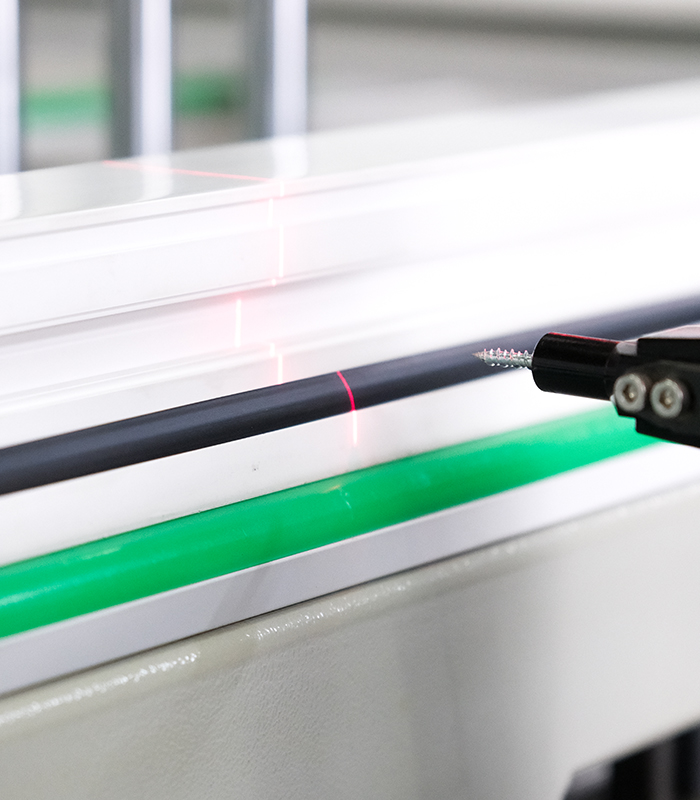

- Laser screw alignment system

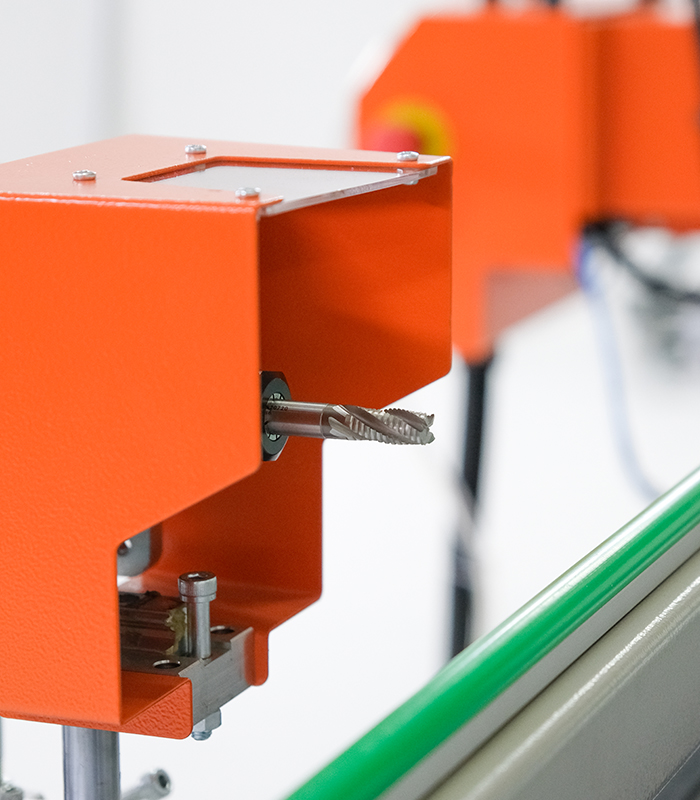

- Triple drilling holes for the handle

- Semi automatic adjustable hinge drilling and manual hinge drilling

- Screwing group

- Milling channel for espagnolette

- Shelf for accessories

Optional Features

- Double Punch System (Stepped)

- Centrifugal system for manual adjustment of handle holes.

Product Description

The SCHTEC SA 280 is a professional machine designed to automatically install tilt-and-turn accessories onto PVC window and door sashes without molds and with high precision. It supports sash sizes from 330 mm to 2.5 m and includes features such as automatic centering, espagnolette and stay measurement, laser-assisted screwing, and triple handle hole drilling. Powered by a 3 kW motor and weighing 615 kg, the SA 280 delivers high performance. Its automatic screw feeding and semi-automatic hinge drilling minimize operator errors and reduce production time. Engineered by SCHTEC, this machine ensures standardized quality and maximum efficiency in sash accessory assembly.

Frequently Asked Questions

Find quick answers to common questions about our Accessory Assembly Machines.