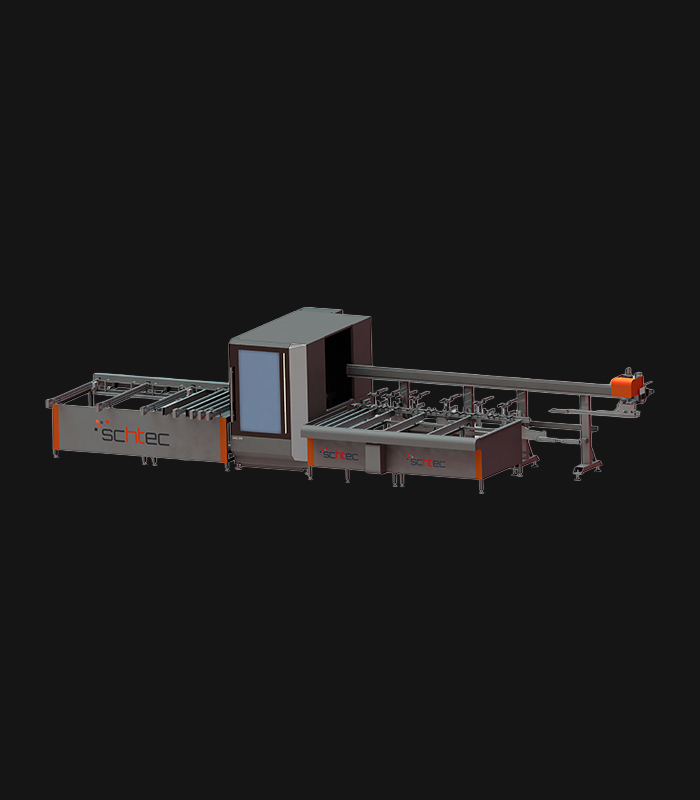

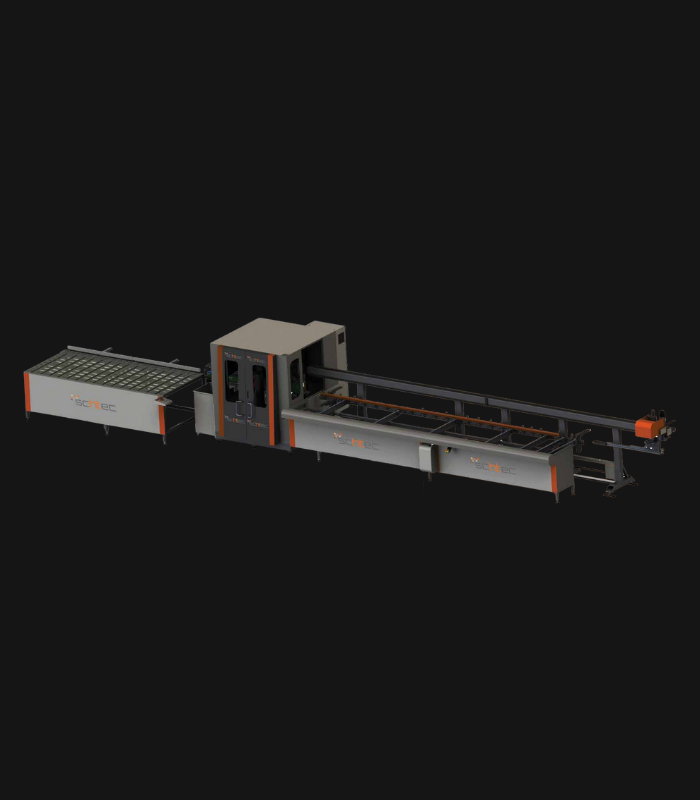

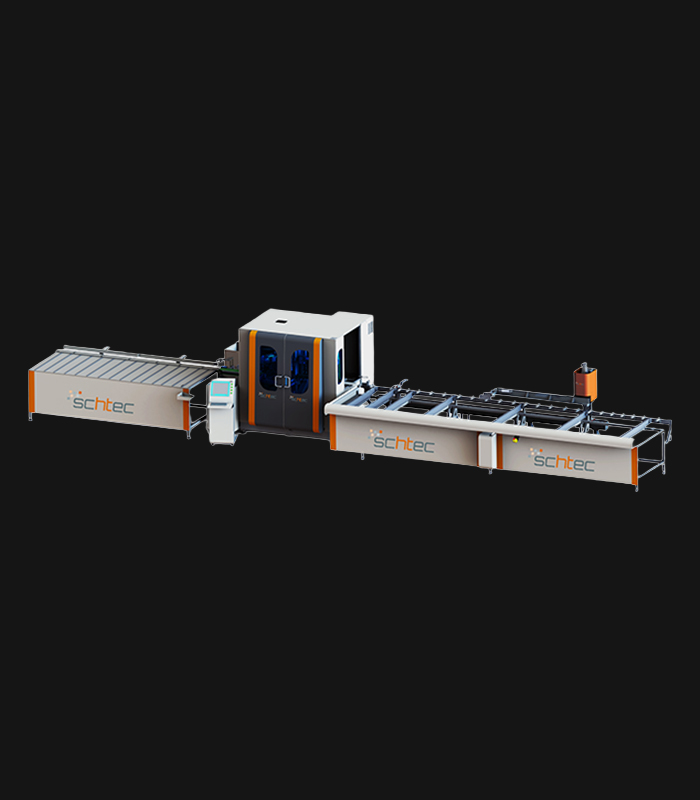

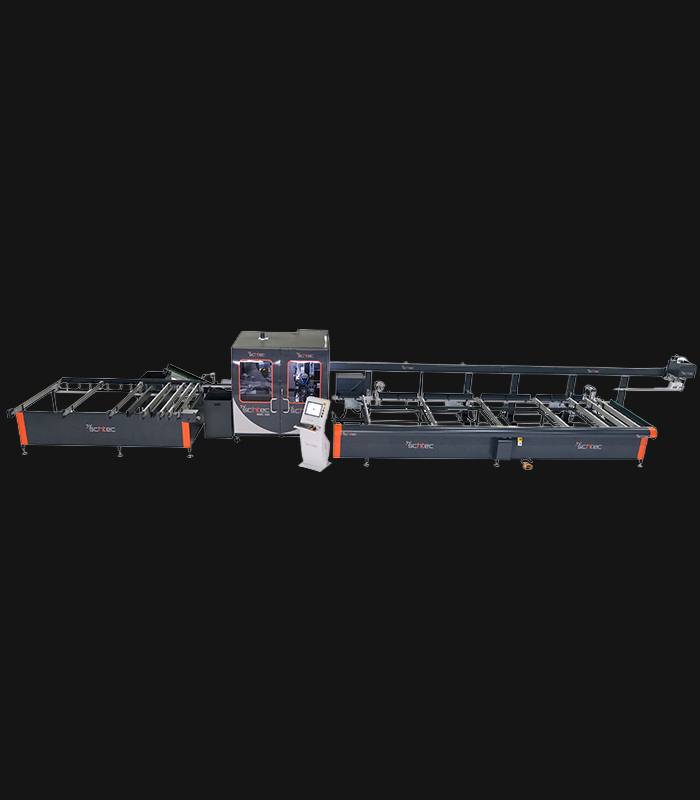

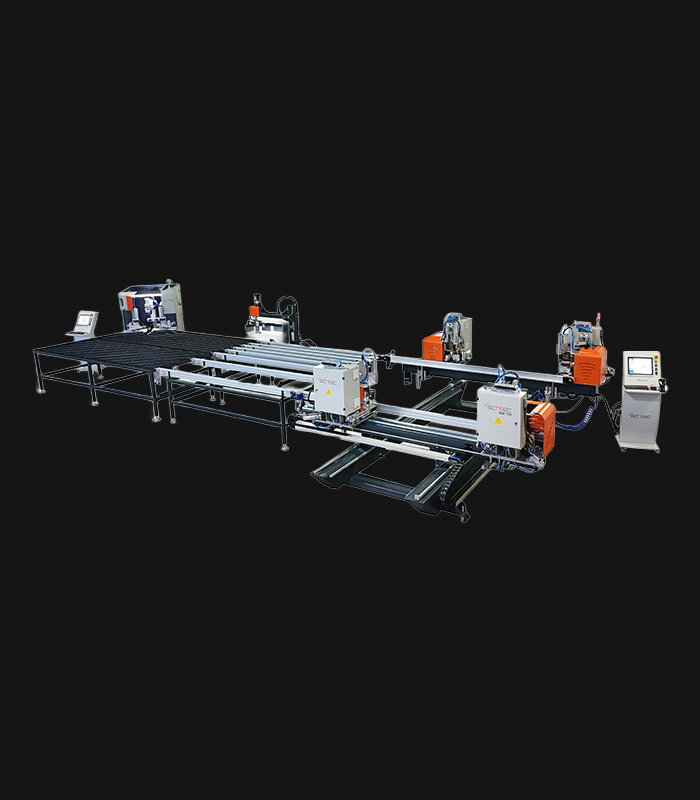

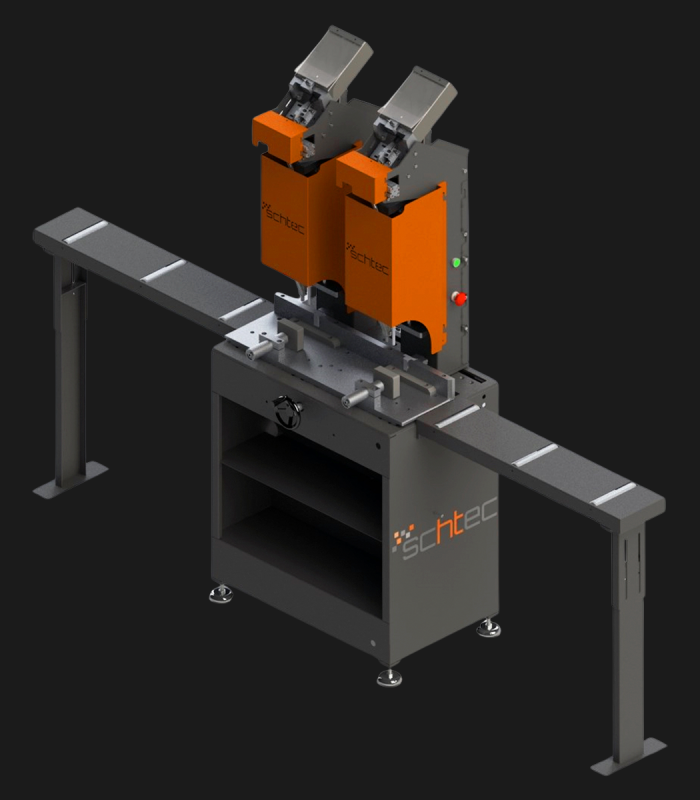

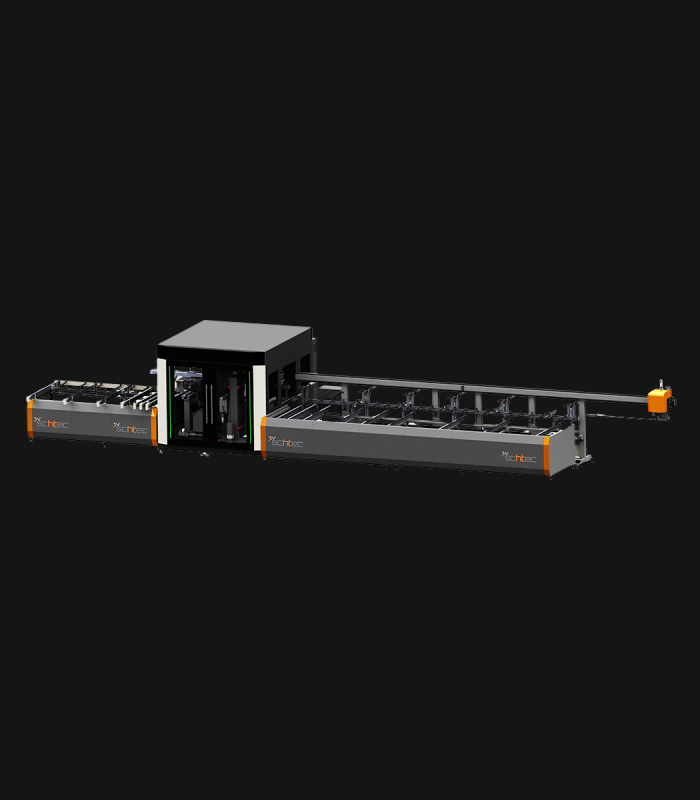

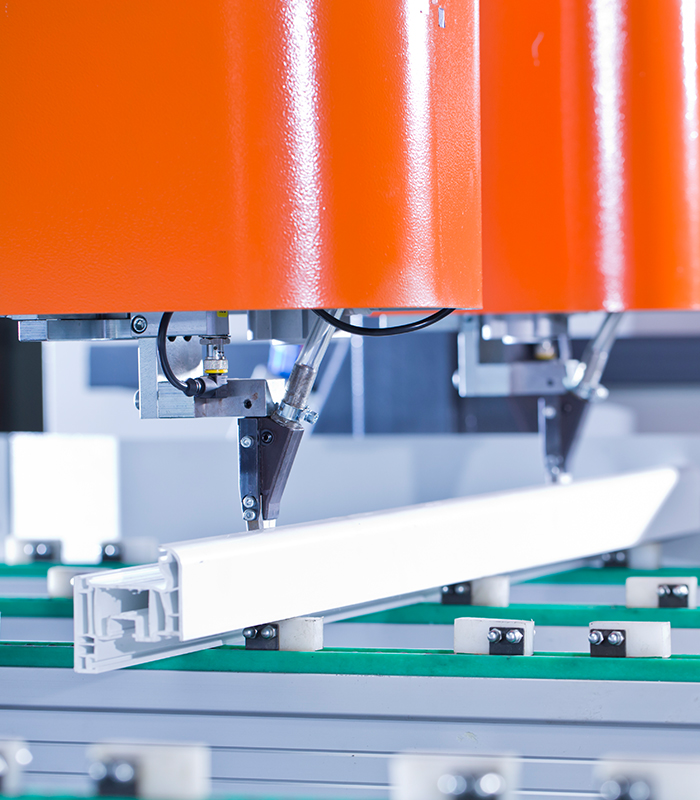

RS 225 Profile Screwing Center

Schtec RS 225: Precise screwing for PVC profiles. Dual servo motors, 8-profile loading, 10,000-position memory for fast, automated production up to 4,500 mm.

RS 225 Technical Specifications

| Power Supply | 400 V, 3ph, 50-60 Hz |

| Power Consumption | 6.8 kW , 17 A |

| Air Pressure | 6-8 bar |

| Air Consumption | 110 lt./min. |

| Min. Piece Length | 400 mm |

| Max. Piece Length | 4.500 mm |

| Max. Profile Height | 130 mm |

| Min. Profile Height | 30 mm |

| Max. Profile Width | 130 mm |

| Machine Height | 2.850 mm |

| Machine Length | 5.695 mm |

| Machine Width | 4.540 mm |

| Machine Weight | 1.820 kg |

Standard Features

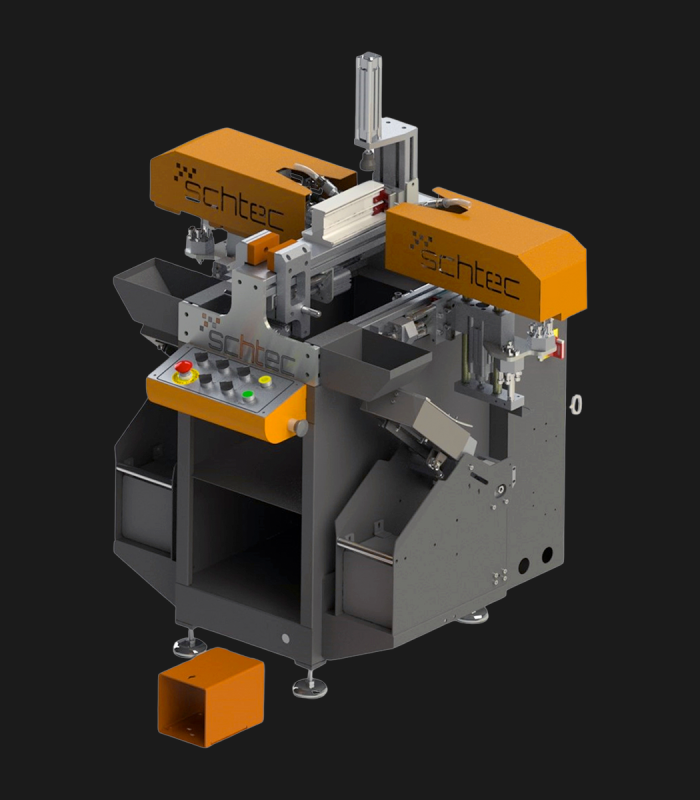

- Screwing operation process done simultaneously by two separate fully automatic screwing axis controlled units

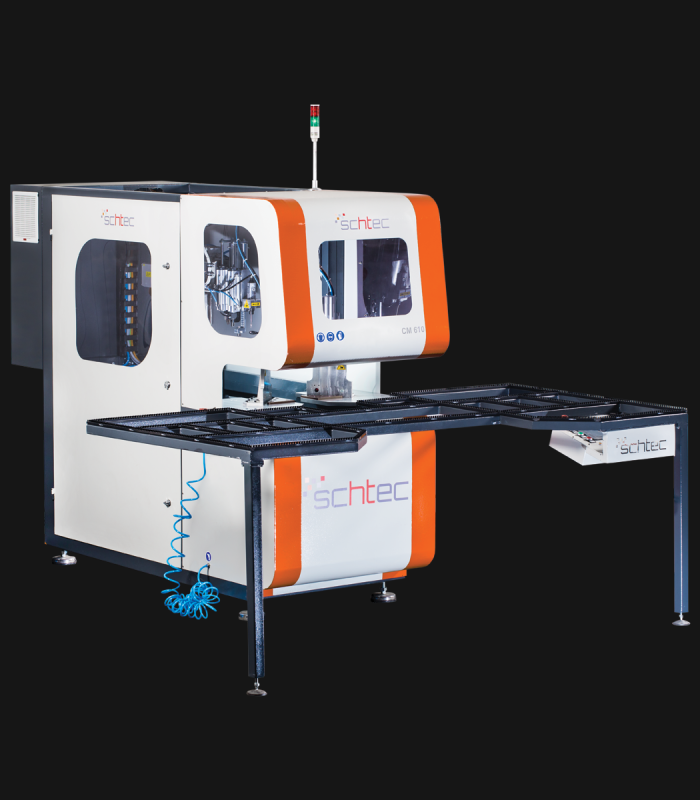

- Machine is fully compatible with Processing center in automatic operation

- Servo controlled automatic positioning with 0.1 mm precision for each screwing position

- Precision positioning at 0.1 mm accuracy by high-speed servo on the holder axis

- Up to 8 pieces can be loaded on to the loading station

- Screwing parameter data bank can be defined by the user for each profile (up to 10,000 profiles)

- All machine axes are moved by hardened steel ball screw and rack-pinion gear system that provides accuracy and durability.

- Data transfer by via ethernet connection, wireless network connection, USB interface or directly through the barcode reader

- All error messages and system status information can be observed on the screen by using the HMI software program developed by the Schtec software department

- Service, trouble shooting and trouble removal can be done by remote connection for the entire system

- Beckhoff brand, high performance industrial PC operated by Windows XP Embedded system. Works between 0°C and 55°C without a fan. 15” touch screen display. (This feature valid when screwing center operates separately from the machining and cutting center)

Optional Features

- Case Wall Mounting Hole Drill Option (OPT-1)

Product Description

The Schtec RS 225 is a high-precision production center developed for the automatic screwing of PVC profiles. With a servo motor-controlled dual screwing unit, it performs operations simultaneously, minimizing production time. It supports intensive production lines with a loading capacity for 8 profiles and a memory bank of 10,000 positions. Capable of processing profiles up to 4,500 mm, it offers full automation and a user-friendly experience through its HMI interface.

Frequently Asked Questions

Find quick answers to common questions about our Fully Automatic Profile Screwing Centers.

1. What is the core function of a profile screwing center in PVC production?

A profile screwing center automatically inserts and tightens screws into PVC profiles at predefined positions, reducing manual effort and errors. It ensures high consistency in hardware mounting across large volumes. These machines are often integrated with profile machining and cutting centers to form a continuous production line. With precise positioning and programmable parameters, they help maintain tight tolerances and uniform assembly quality.

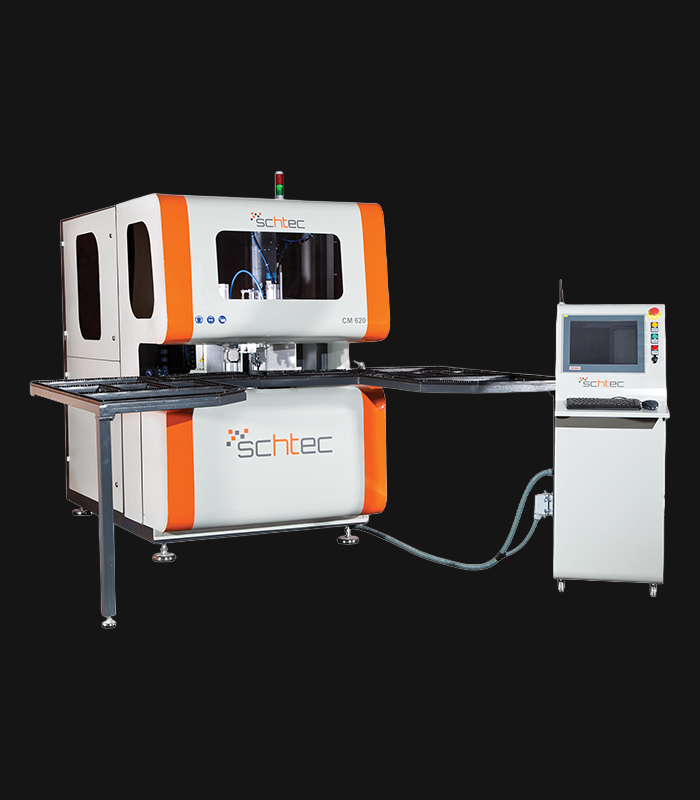

2. What distinguishes RS 225 from other screwing machines in this category?

The RS 225 Profile Screwing Center features dual fully automatic screwing axes that work simultaneously, enhancing throughput and reliability. Servo‑controlled positioning ensures 0.1 mm precision per screwing position. The machine supports loading up to 8 profiles and maintains a database of screwing parameters (up to 10,000 profiles). It also allows for remote diagnostics and is compatible with machining centers in an automated workflow.

3. What advantages does the RS 235 Fully Automatic Screwing Profile Centeroffer?

4. Can these screwing centers adapt to different PVC profile designs and hardware configurations?

5. What maintenance practices help ensure reliability and longevity in screwing centers?

Regular cleaning of screw feeding systems, sensor windows, and guide rails prevents dust or debris from influencing accuracy. Lubrication of moving parts, ball screws, and rack‑pinion mechanisms is essential to reduce wear. Periodic calibration of servo axes and position detection systems keeps tolerances tight. Checking pneumatic lines, seals, and air pressure ensures consistent screw insertion force. Finally, monitoring error logs and remote diagnostics helps preemptively resolve issues before breakdowns occur.