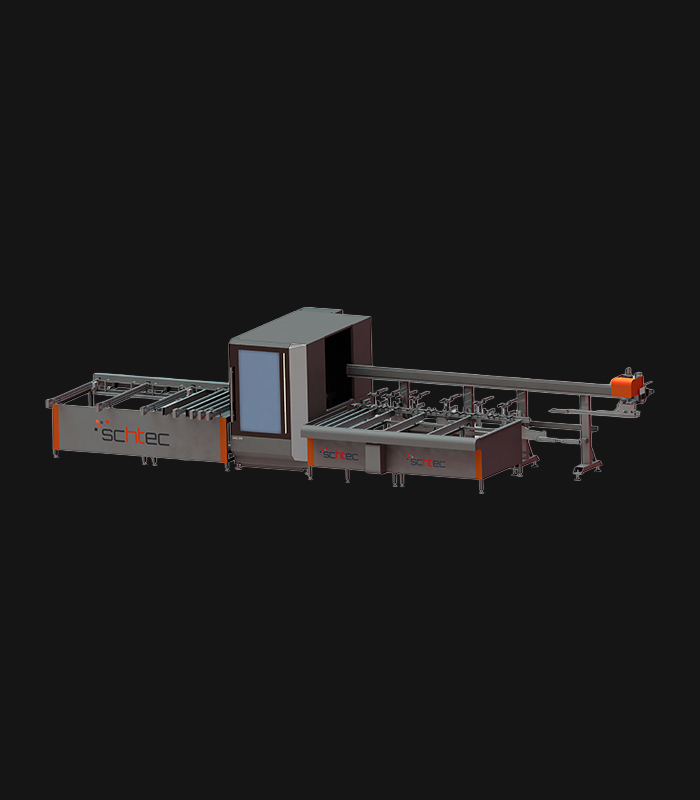

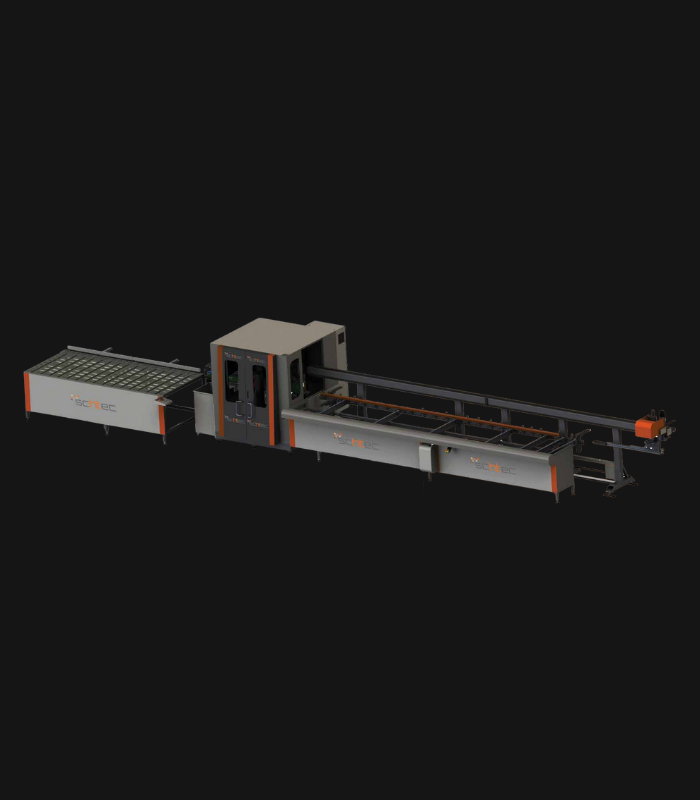

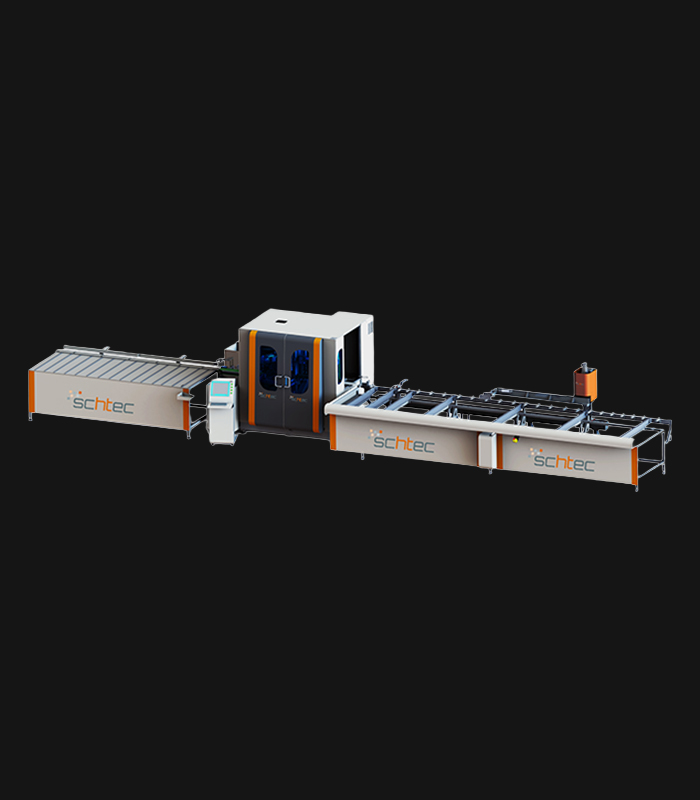

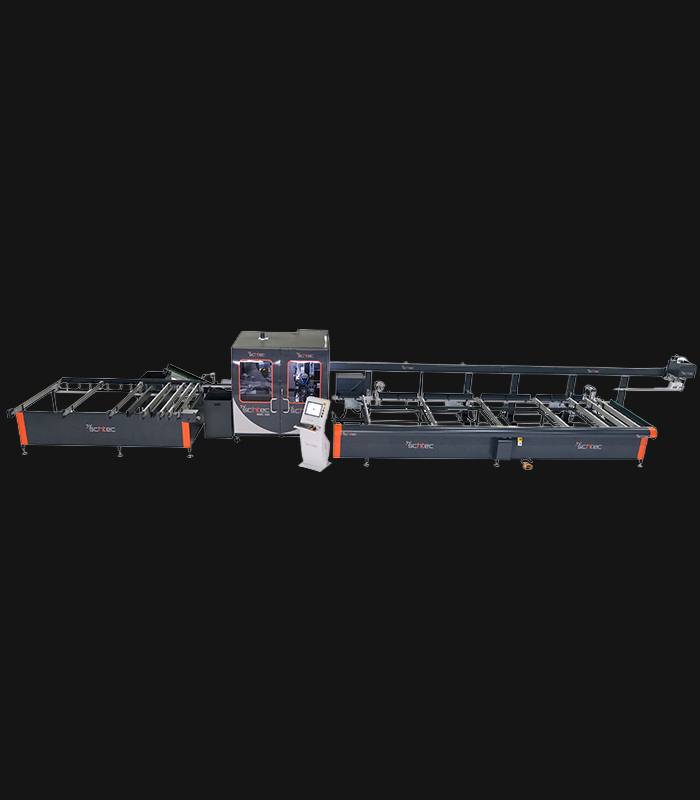

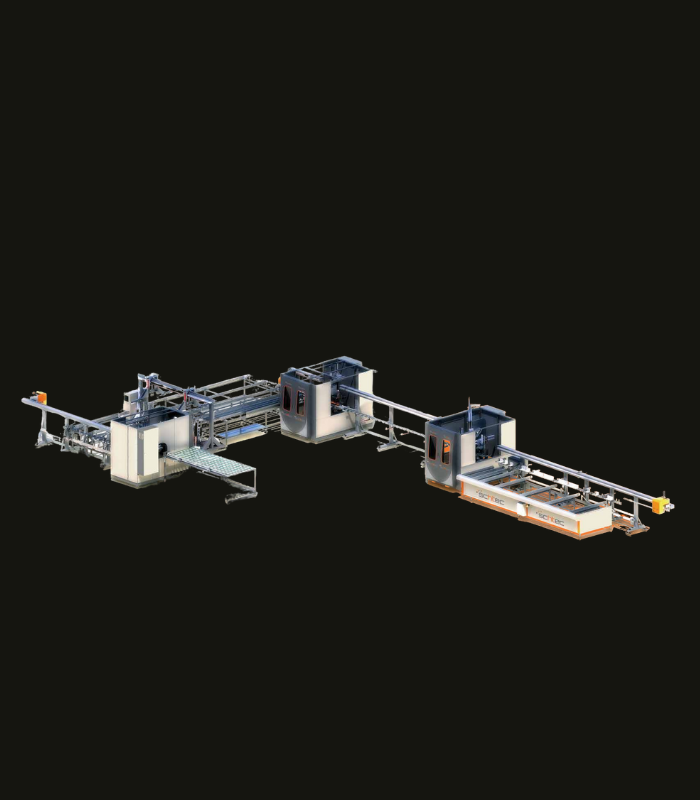

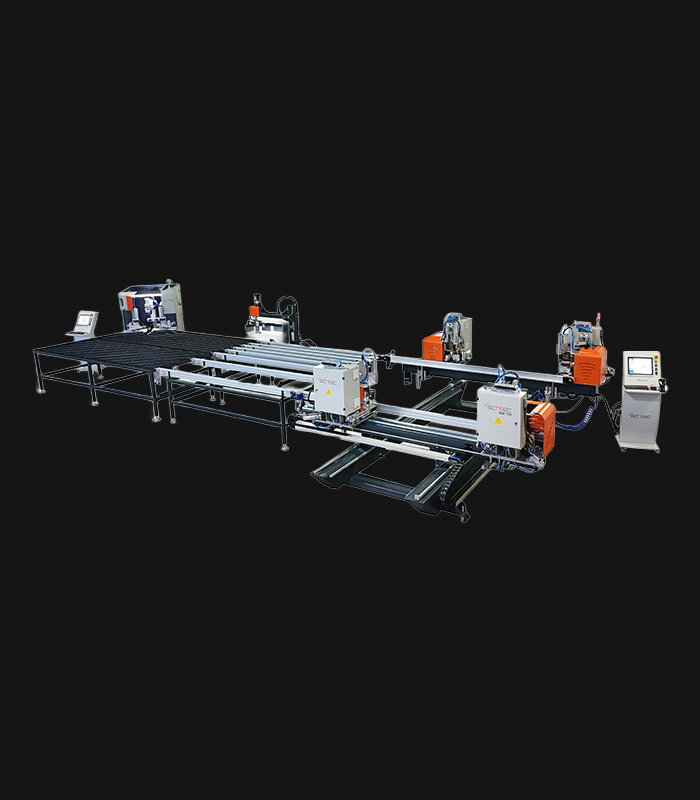

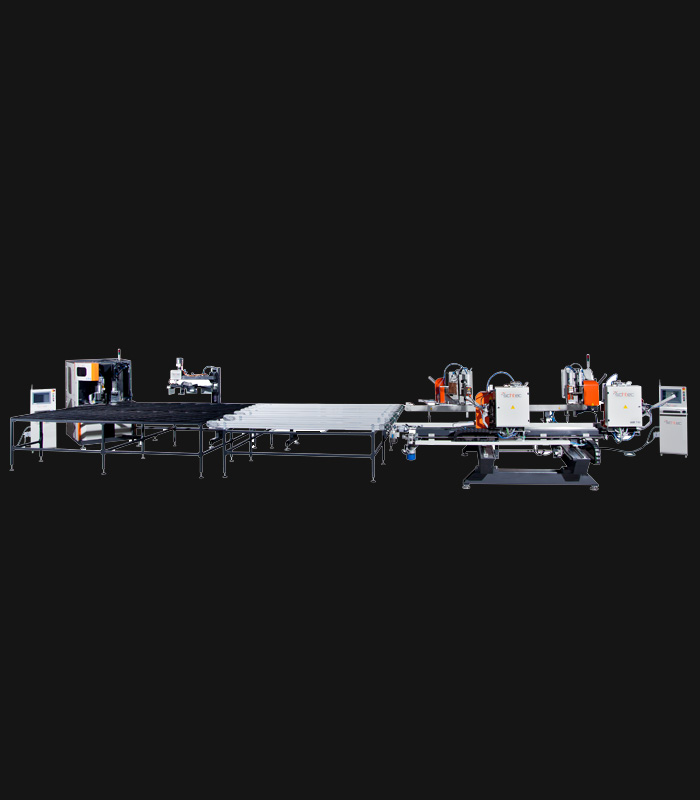

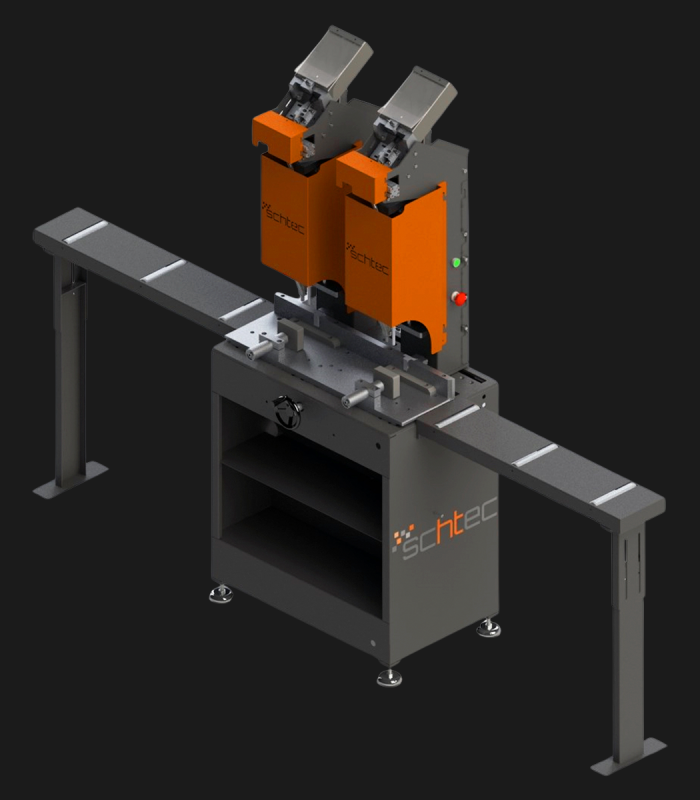

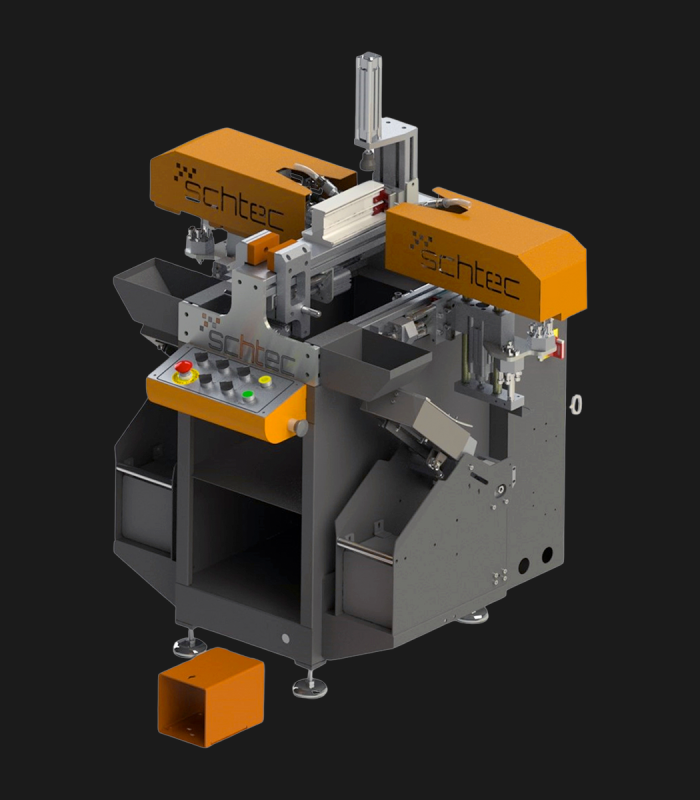

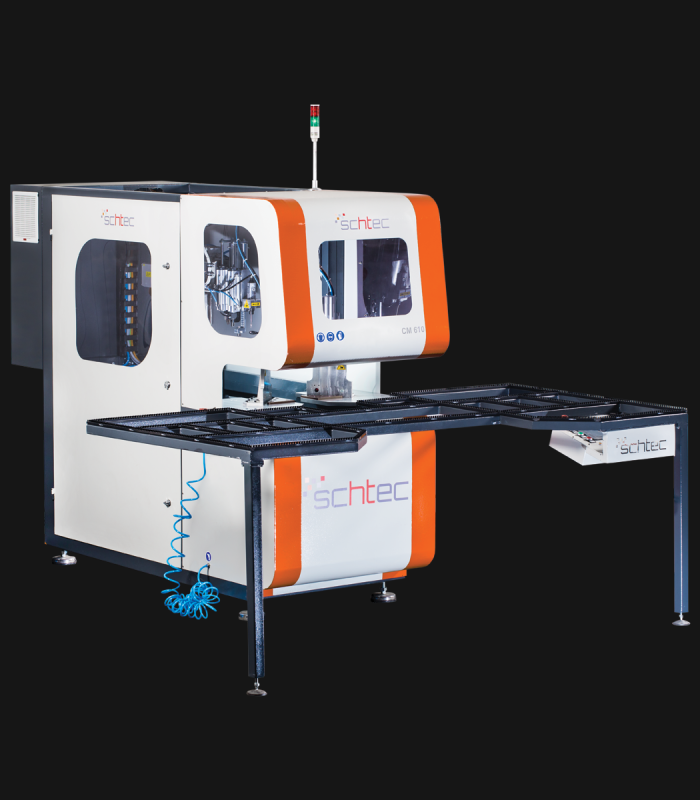

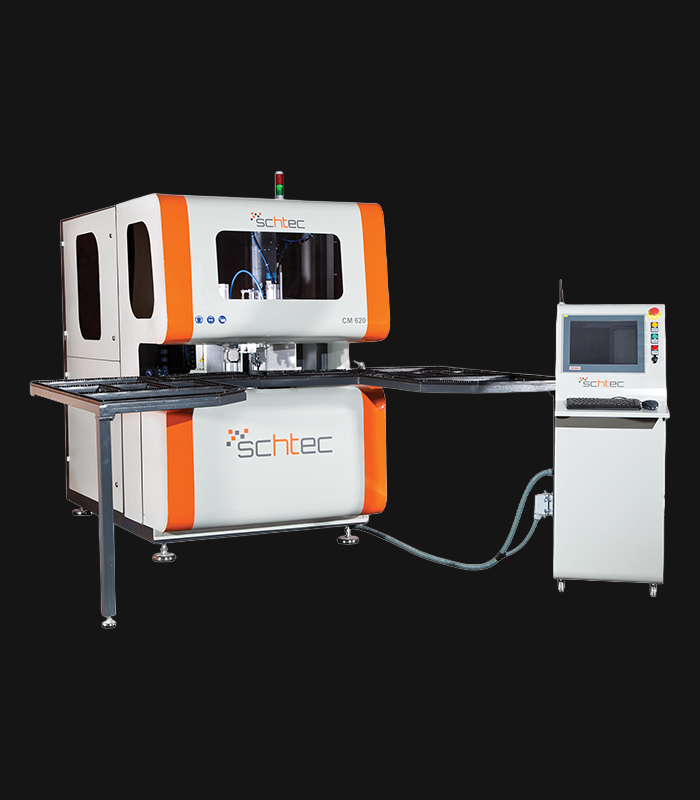

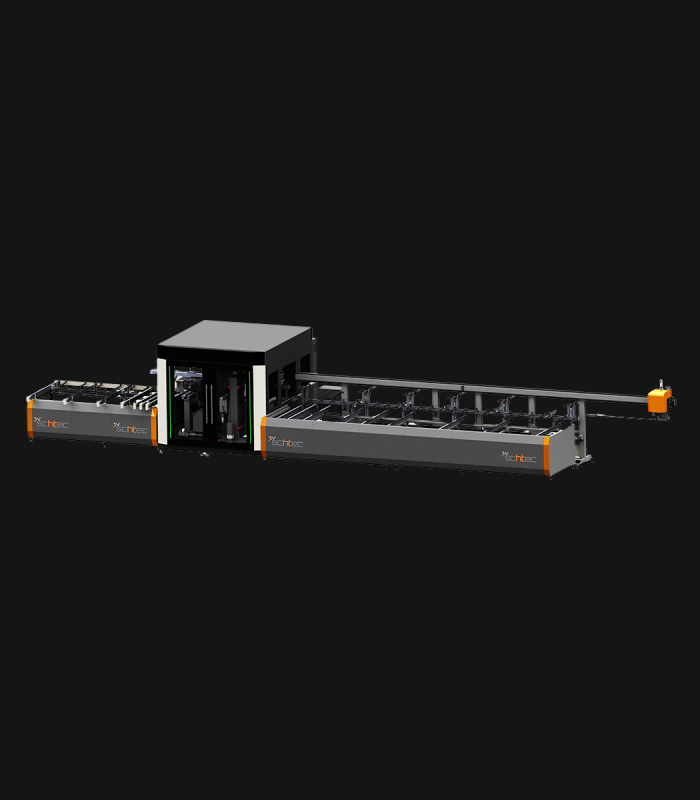

DCA 435 Double Head Aluminium & PVC Cutting Machine

SCHTEC DCA 435: Fully automatic aluminum & PVC cutting, 0.1 mm precision, 45°-135° angles, 6.5m length, 550 mm blades, Beckhoff software for efficient production.

DCA 435 Technical Specifications

| Power Supply | 400 V, 3 Ph, 50-60 Hz |

| Total Power | 7.2 kW |

| Power Output of Each Motor | 3 kW |

| Diameter of Saw Blade | 550 mm |

| Saw Blade Speed | 2,800 rpm |

| Cutting Length | 250 mm - 6,500 mm |

| Air Pressure | 6-8 bar |

| Air Consumption | 60 l/min |

| Machine Height | 1,935 mm |

| Machine Length | 8,100 mm |

| Machine Width | 1,950 mm |

| Machine Weight | 2,650 kg |

Standard Features

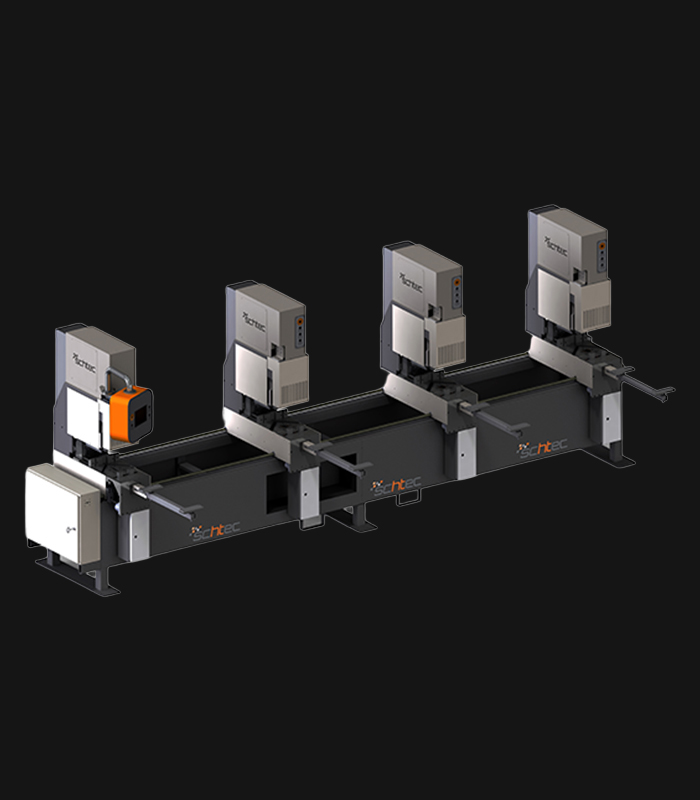

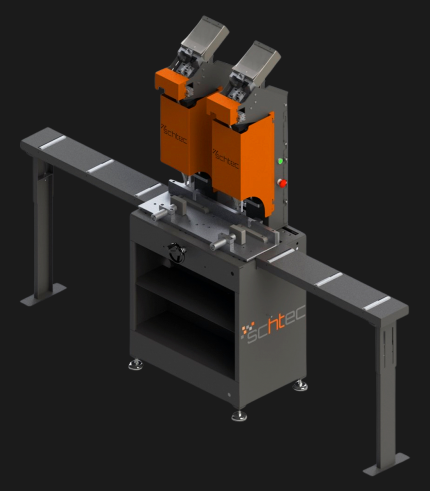

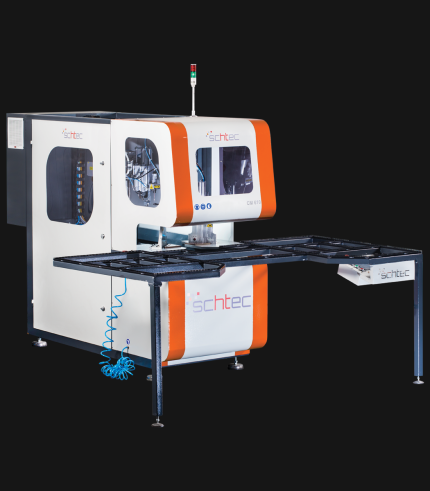

- Cutting of Aluminum & PVC profiles with high speed and precision thanks to 3-axis servo system

- Strong construction, lineer rail and sliding-bearing system for precise length and angle

- Industrial PC Based Servo Control System, 10 touch screen (Beckhoff)

- Ethercat based controlled drivers and high-torque servo motors

- Remote desktop connection by way of Wifi or Network connection

- File transfer via USB or Network

- Central lubrication system

- All error messages can be seen on the machine screen with the interface program which developed by SCHTEC Software R&D Department.

- Remote connection method and problem detection and solution by connecting to all automation system

- High angle accuracy thanks to cycloid gap free gearbox

- Profile height automatically transferred from profile data

- Automatic aluminum corner block cutting

- Cooling system to cut Aluminium profiles

- Hydro-pneumatic system to cut Aluminium profiles

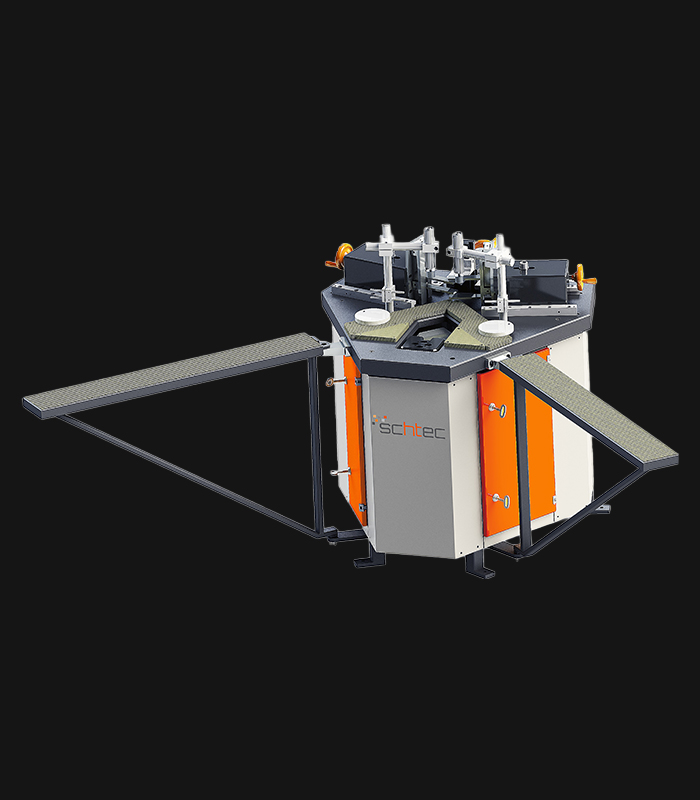

- The saw heads tilt automatically between 45° and 135° by servo motors

- Machine can make single cuts

- Adjustable saw cutting speed

- Profile support conveyor is available on the machine as standard

Product Description

The SCHTEC DCA 435 is a fully automatic double-head aluminum & PVC processing machine designed for precise angular operations between 45° and 135°. Equipped with a 550 mm saw blade and a servo-assisted 3-axis system, it operates with high speed and stability, even on large profiles. Its hydro-pneumatic drive enhances processing quality while minimizing maintenance needs. With a capacity of up to 6.5 meters, a user-friendly interface based on Beckhoff, and Schtec software, it offers efficiency and precision in production.

Frequently Asked Questions

Find quick answers to common questions about our PVC Cutting Machines.