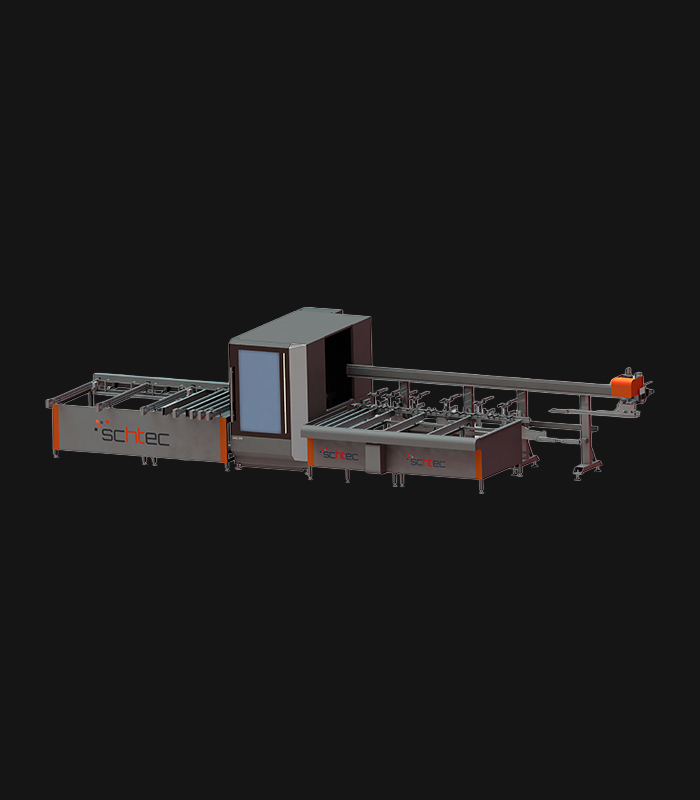

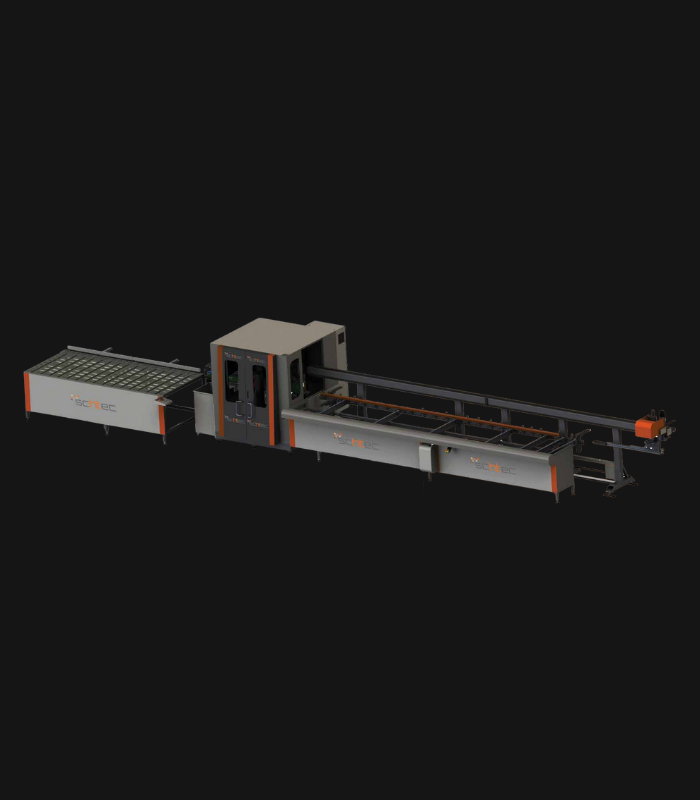

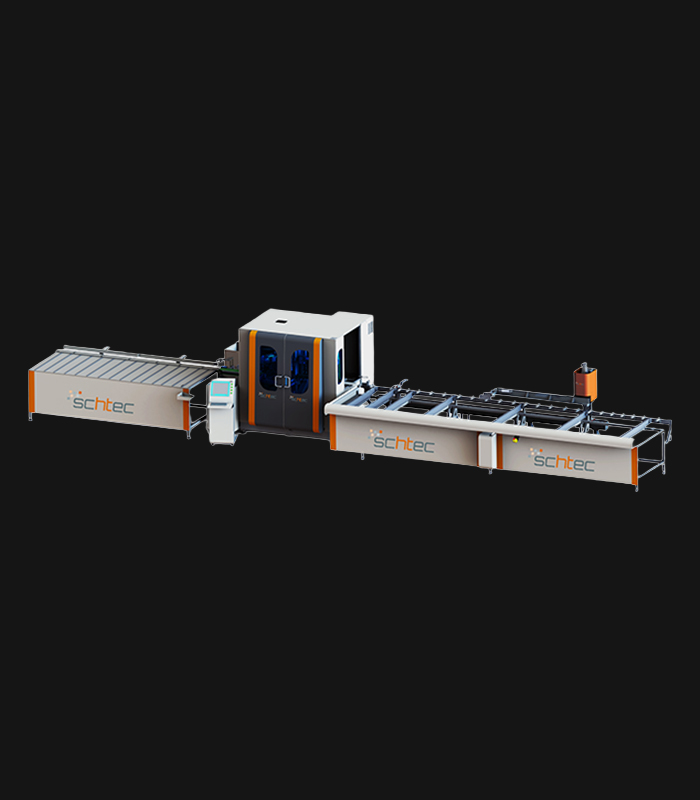

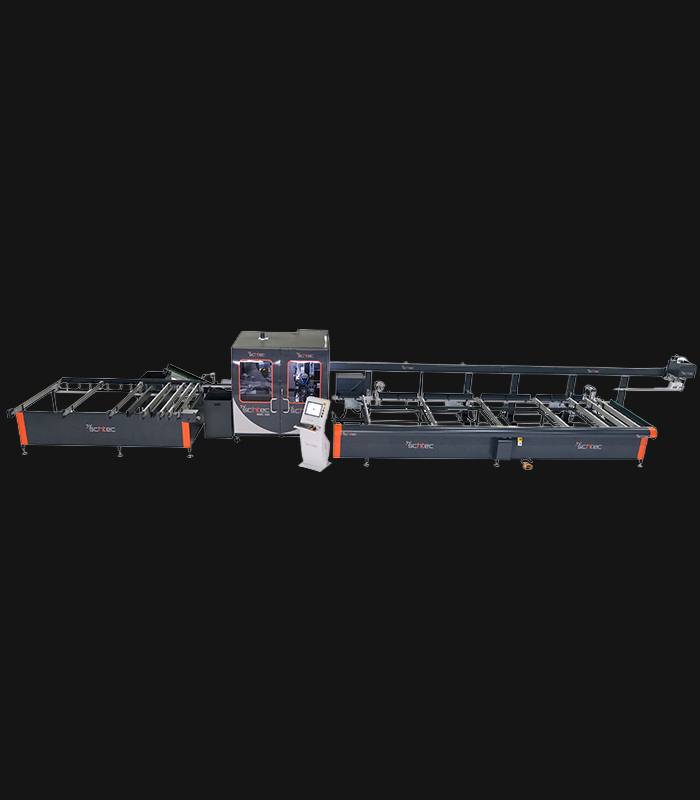

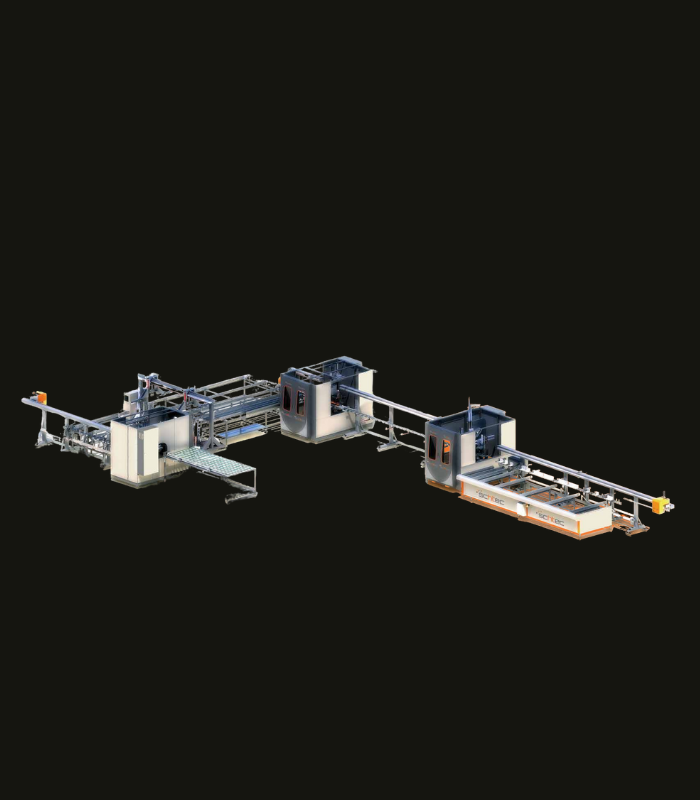

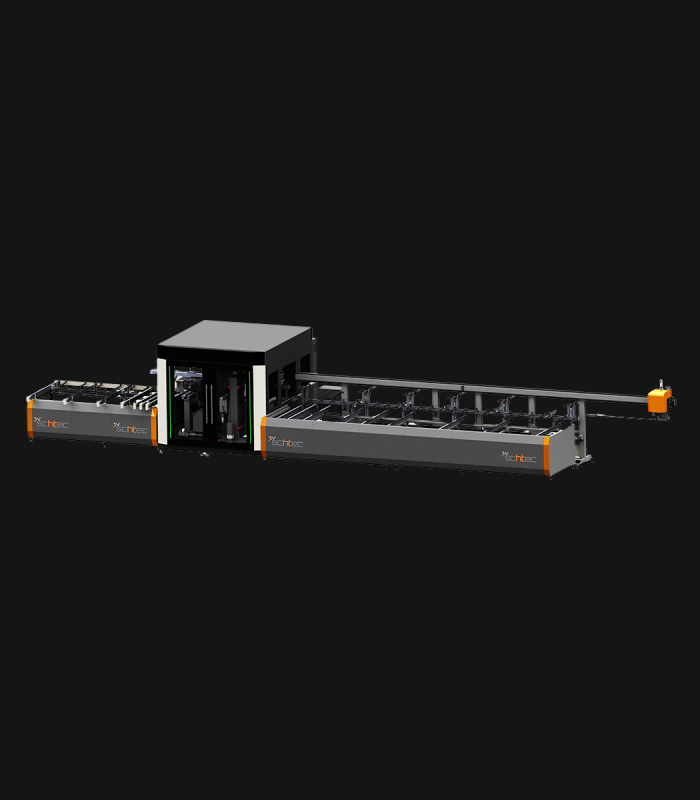

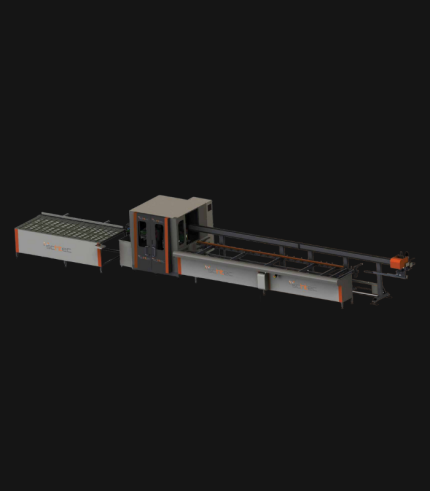

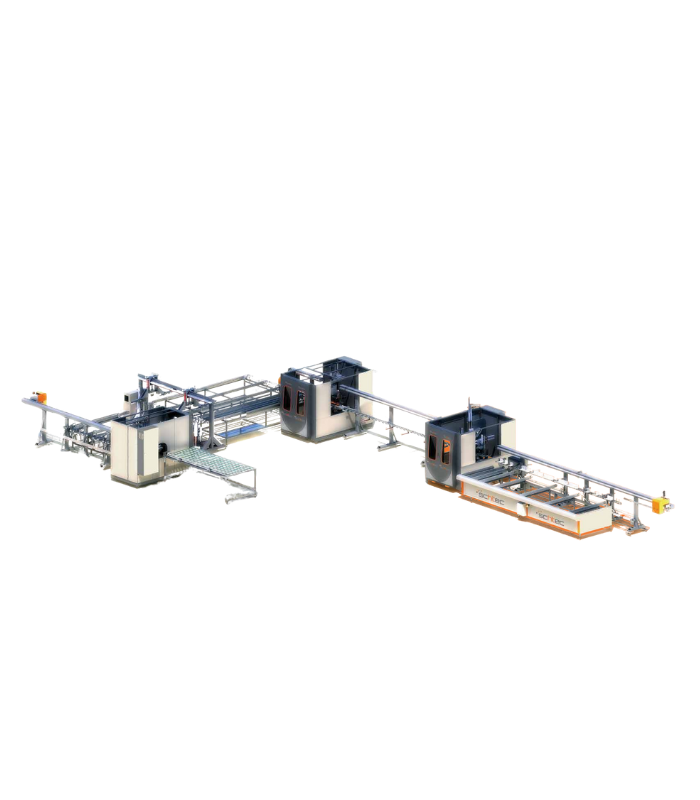

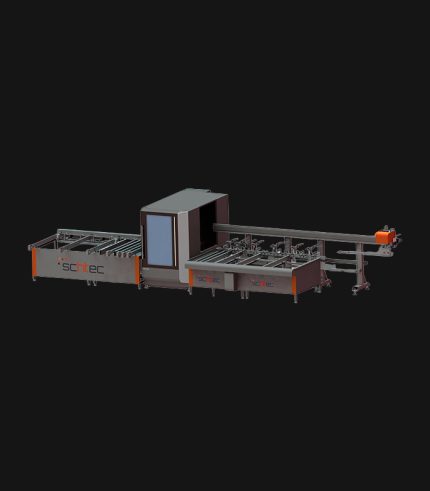

CSML 240 Fully Automated Processing Center

SCHTEC CSML 240: High-tech CNC solution for PVC profiles with 21 tools, dual screwing units, and full automation of cutting, drilling, slotting, and marking processes. Features advanced servo axis control, profile optimization, barcode printing, and Industry 4.0-ready connectivity—ideal for high-volume, precision-driven window and door production.

CSML 240 Technical Specifications

| Power Supply | 400 V, 3 Ph, 50-60 Hz |

| Power Consumption (Processing Station) | 12 kW / 30 A |

| Power Consumption (Cutting Station) | 14 kW / 35 A |

| Power Consumption (Screwing Station) | 4 kW / 10 A |

| Power Consumption (Machining with Reinforcement) | 12 kW / 30 A |

| Max. Profile Processing Height | 215 mm |

| Min. Profile Processing Height | 40 mm |

| Max. Profile Processing Width | 145 mm |

| Min. Profile Processing Width | 35 mm |

| Max. Profile Bar Length | 6.500 mm |

| Max. Process Length for Profile | 6.000 mm (up to 6.500 mm) |

| Min. Process Length for Profile | 700 mm |

| Maximum Cutting Length | 4.500 mm (can be increased up to full bar length) |

| Minimum Cutting Length | 400 mm |

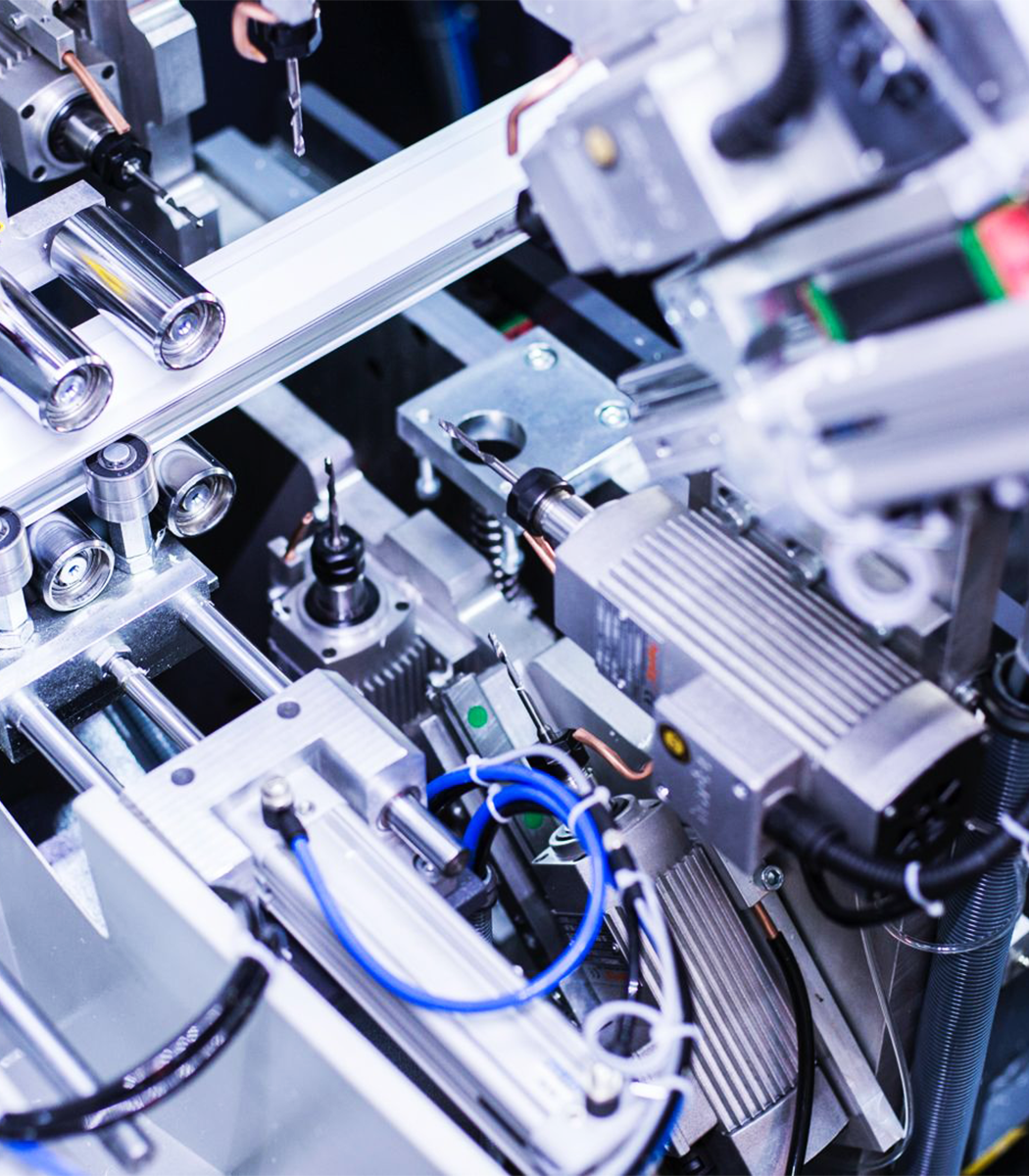

| Tool Diameter | 6 mm / 8 mm / 10 mm / 12 mm Carbide Fast Tool (Two different types selectable per surface) |

| Tool RPM | 900 / 6000 / 12000 / 18000 rpm |

| Max. Axis Speed (Processing) | 50 m/min |

| Max. Axis Speed (Saw) | 100 °/sec |

| Max. Axis Speed (Carrier) | 40 m/min |

| Air Pressure | 6-8 bar |

| Air Consumption | 1075 lt./min |

| Machine Height | 2.300 mm |

| Machine Length | 25.930 mm |

| Machine Width | 10.800 mm |

| Machine Weight | 11.000 kg |

| Standard Tool Count | 21 pcs high-speed, air-cooled spindles (4 different RPM settings per process) |

Standard Features

- All gripper stations on the machine are with high-speed Linear Axis control.

- Gripper axis is equipped with 90 degrees rotating axis in order to minimize the issues in gripping of different types of profiles.

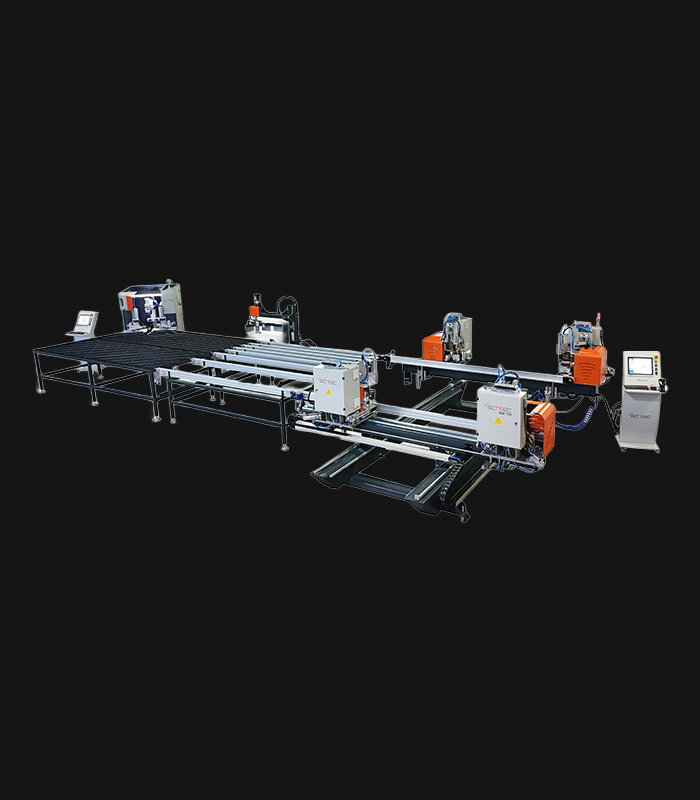

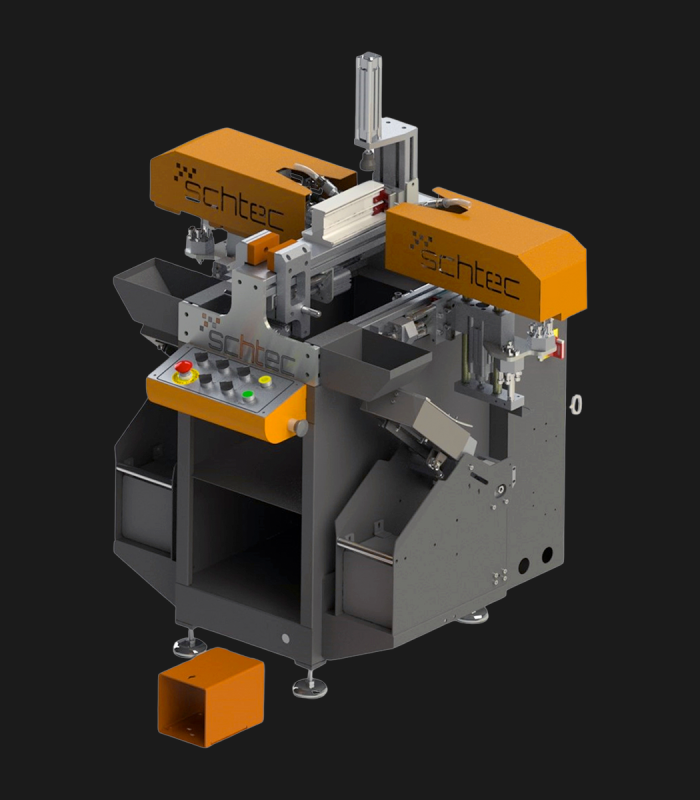

- All channel, drilling, marking, barrel and door handle hole processes on PVC profiles are done without reinforcement metal by CNC controlled 11 tools on high precision L designed 2 separate tool rings.

- In processing station without reinforcement steel two separate L groups are controlled totally by 6 CNC axes.

- While reaching each and every spot on profile, pressing groups are also controlled by 2 different axes for profile fixing.

- 10 tools are used in processes with reinforcement steel. All processes on PVC profiles are done by totally 21 tools with high precision.

- All tools on processing stations can be set at 4 different speeds according to the type of process.

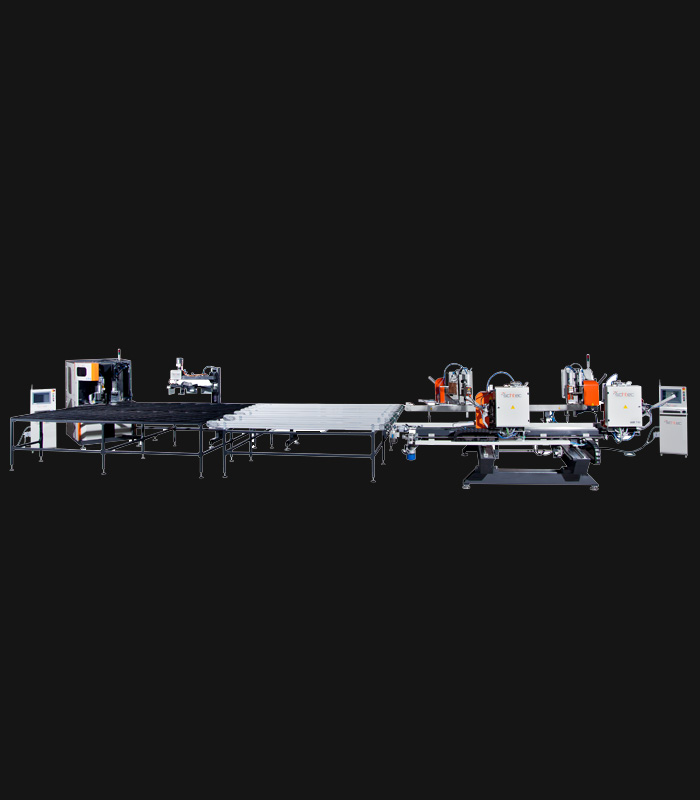

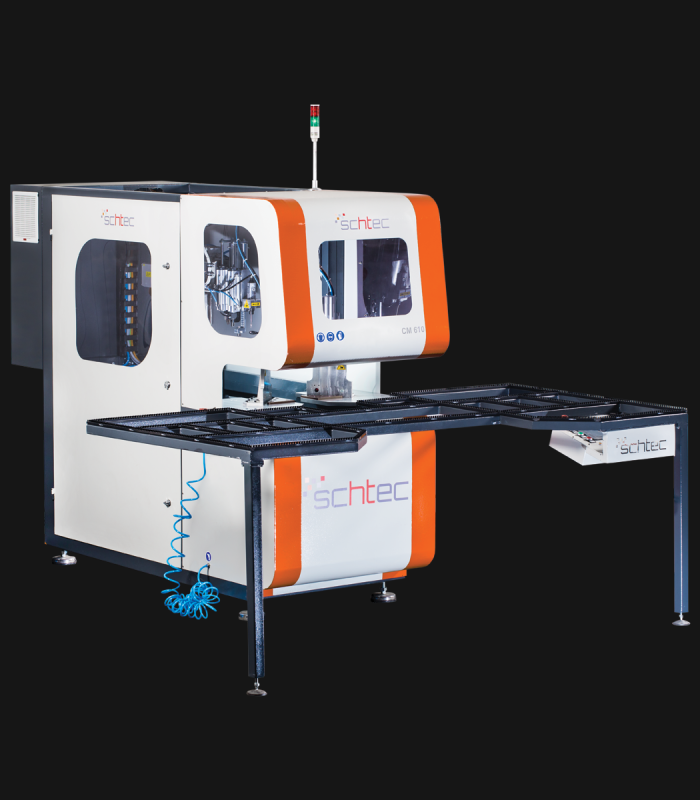

- Cutting of all angles between 45 – 135 degrees with 0.1 degree precision with servo axis controlled 2 pcs. 550 mm and 1 pc. 600 mm diameter blades.

- Fast and rigid cutting with servo axis controlled blade axis that is capable of automatic positioning according to profile height.

- Minimum processing time on door profiles with Milling Unit with reinforcement steel.

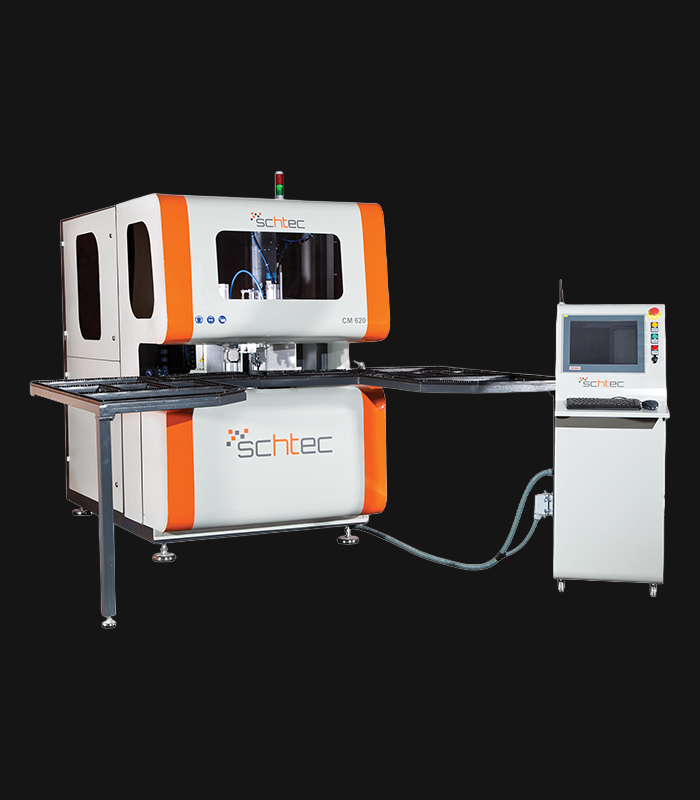

- Total profile loading capacity 10 + 2 bars with profile elevator system on loading station: (10 pcs. on the loading table, 1 pc. on the elevator and 1 pc. in running process) (max. 6.5 meters Length)

- Incorrect profile loading is prevented by controlling of profile width and length values with precise magnetic encoders that is used to minimize user errors.

- All time losses arising from loading time are minimized with elevator systems on loading stations and with independent movement of profile loading stations.

- Cutting and processing of special type of profiles belonging to French, Dutch and English window systems.

- V, Arrow Head and Reverse Butt cutting.

- Cut pieces are swiftly transferred to next station with linear axis movement unloading station.

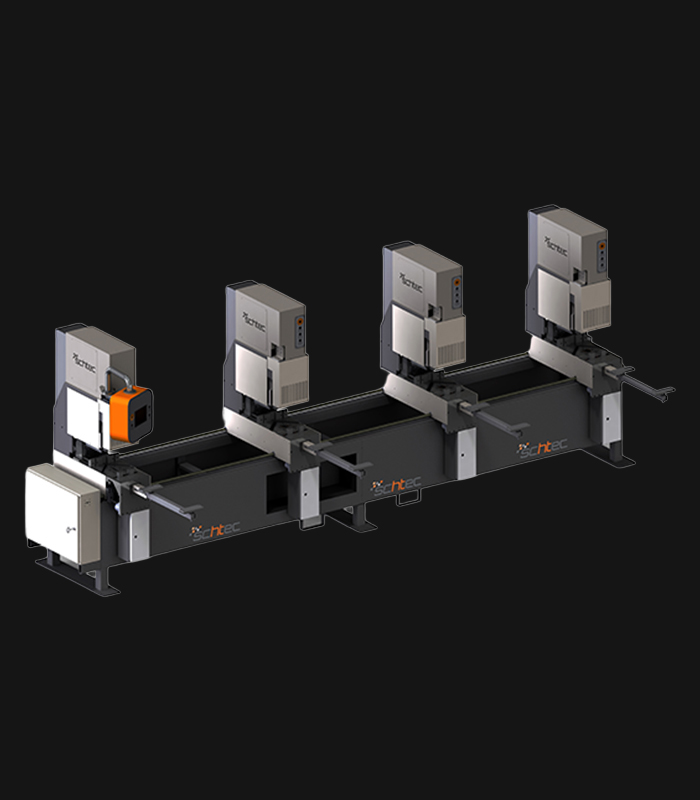

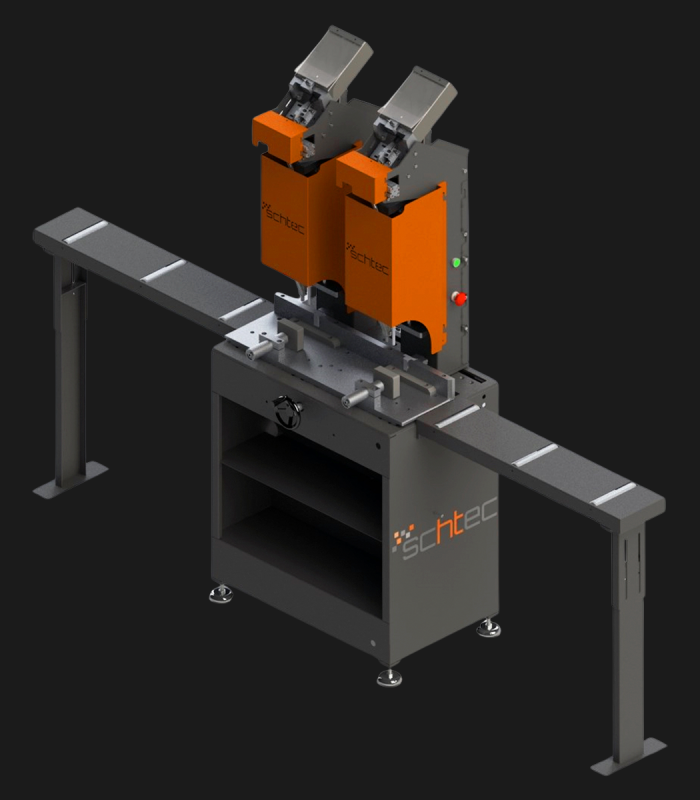

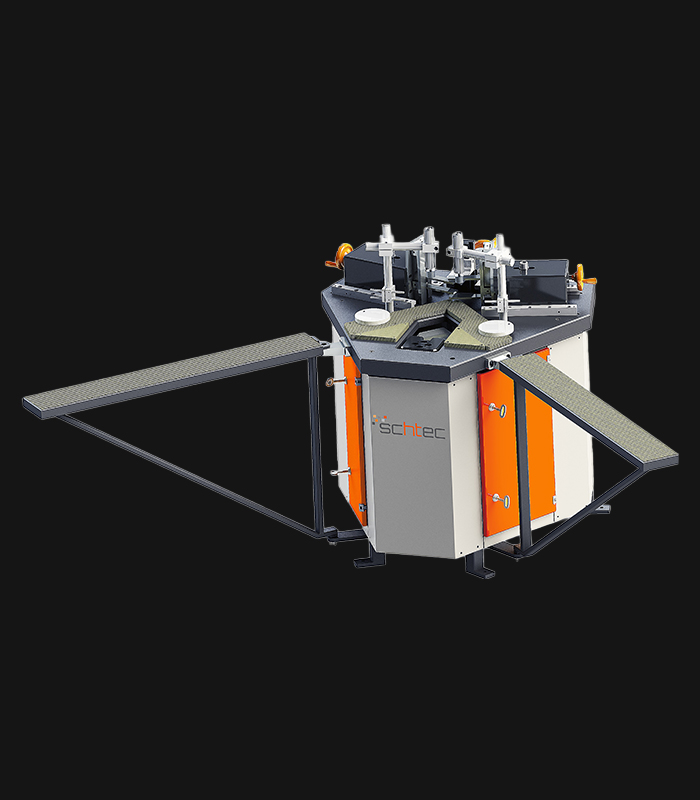

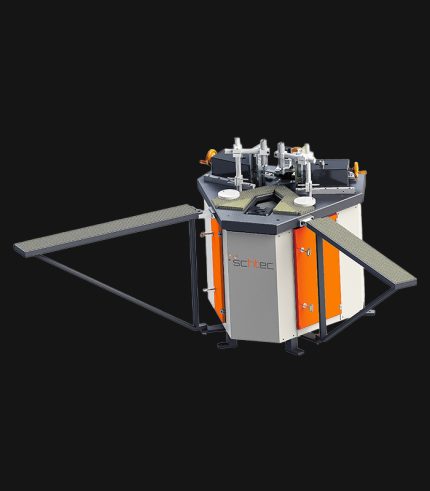

- Simultaneous screwing process is done with 2 full automatic 5 servo axis controlled separate screwing units that are capable of duplex screwing.

- Servo controlled tables and screwing unit provide time saving from screwing of profiles with different heights.

- Seamless and full compatible working with all window drawing programs thanks to the special interface developed by Schtec software department.

- Machine can optimize on waste profiles by itself thanks to simultaneous optimization on machine.

- High performance industrial PC with 15” touch screen and Windows 10 Embedded operating system working between 0°C – 55°C without a fan.

- Industrial PC based control system. (Beckhoff)

- User friendly interface and IQ, online diagnostic and troubleshooting through pneumatic systems BUS control.

- Loading of work files through USB and network and remote connection to the machine.

- Central lubrication system that facilitates machine maintenance.

- Barcode printer

Optional Features

- Linear Servo System

Product Description

The SCHTEC CSML 240 is a high-tech, fully automated processing center designed for cutting, drilling, slotting, and screwing operations on PVC profiles. With 21 specially designed high-speed air-cooled spindles and a 3-axis servo-controlled system, it delivers maximum precision and minimal cycle time. Supporting special cuts for French, Dutch, and English window systems, and equipped with integrated optimization software, it maximizes production efficiency. Its Windows-based industrial PC, user-friendly interface, and remote connectivity offer seamless full automation. Energy-efficient and Industry 4.0 compatible, it’s the ideal solution for next-generation production lines.

Frequently Asked Questions

Find quick answers to common questions about our Profile Processing & Cutting Centers for PVC Profiles