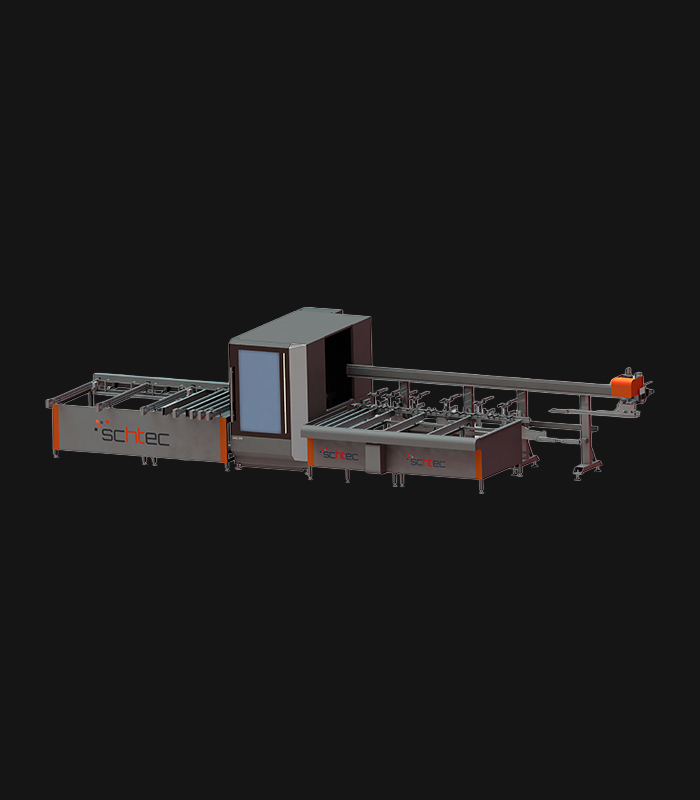

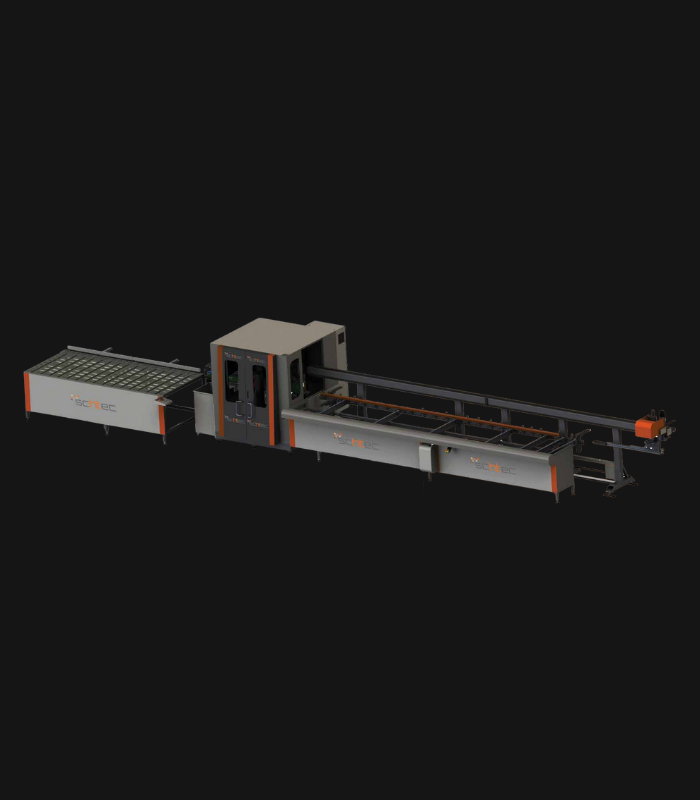

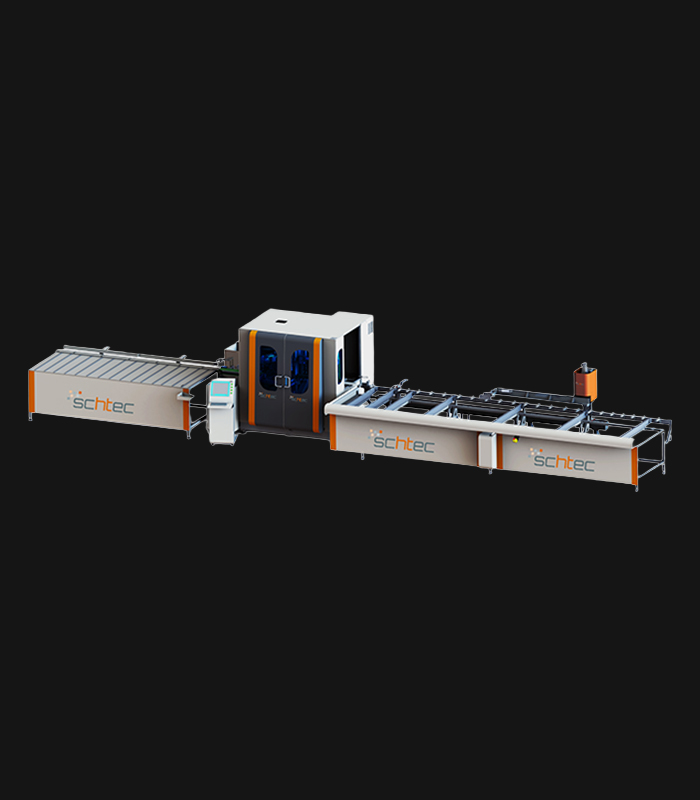

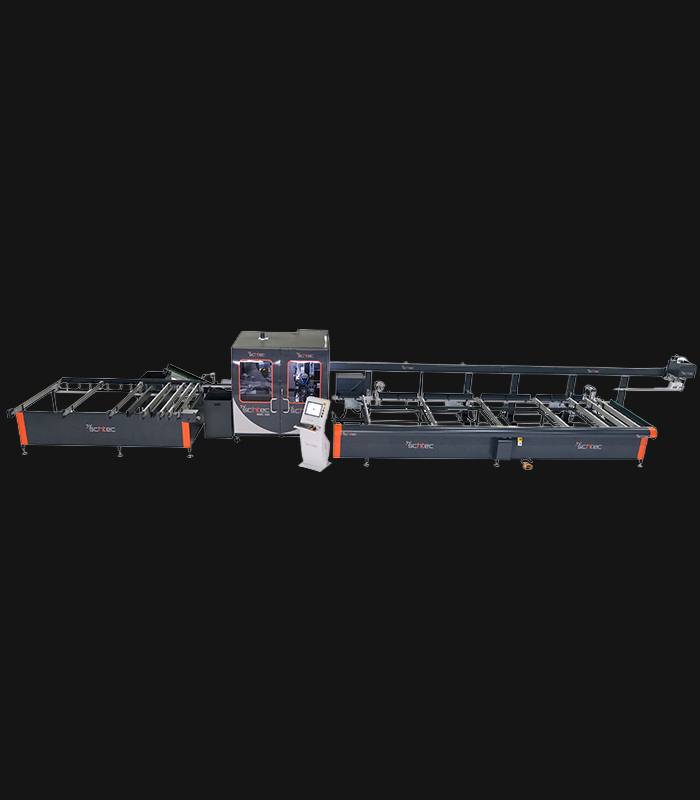

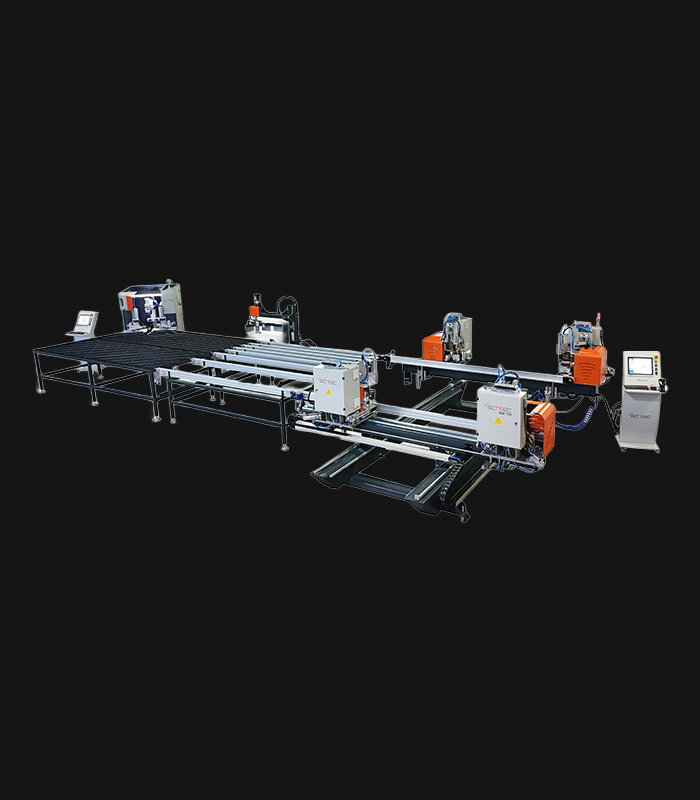

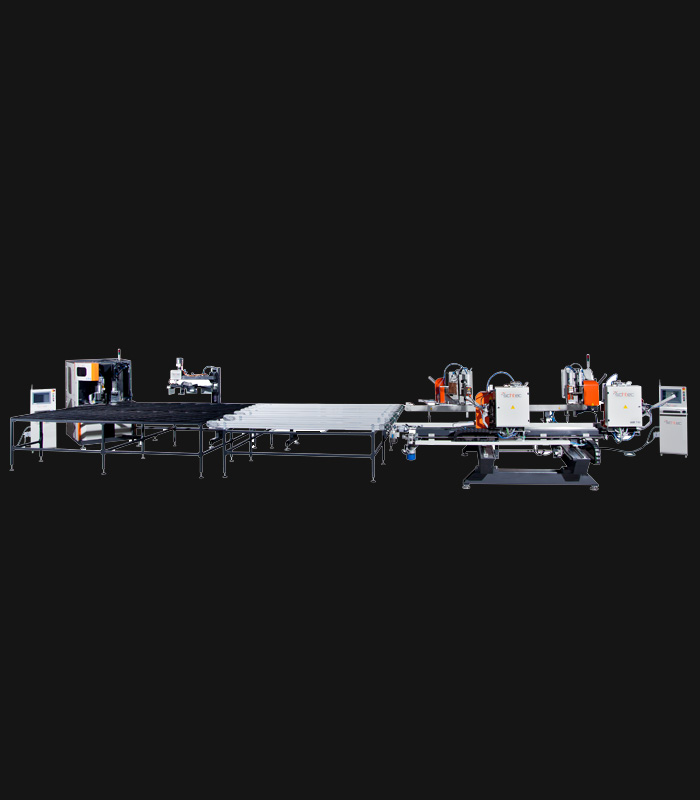

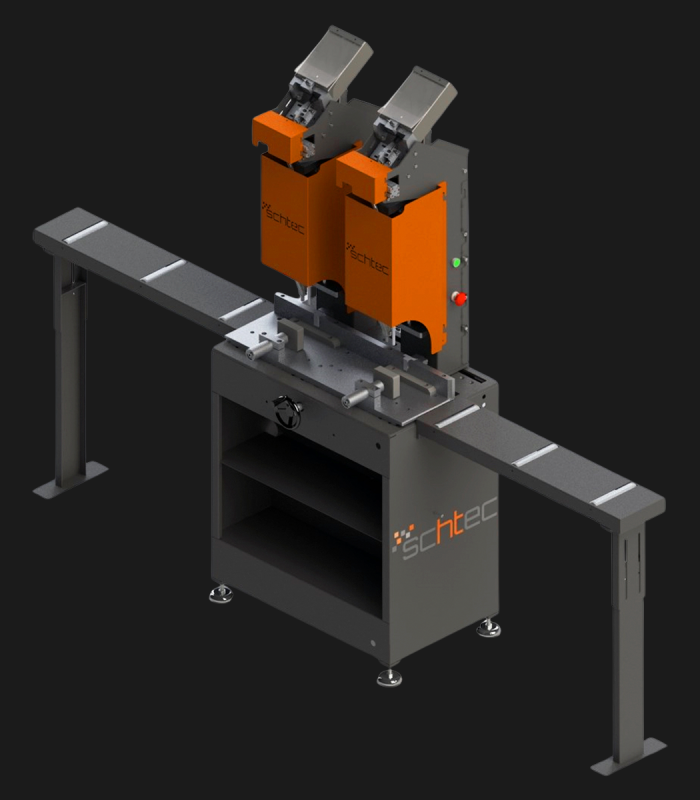

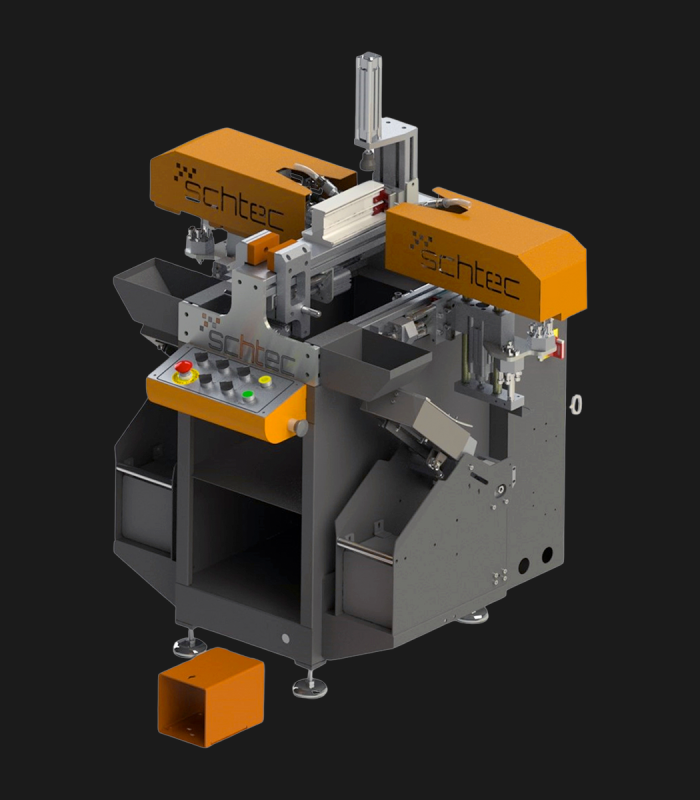

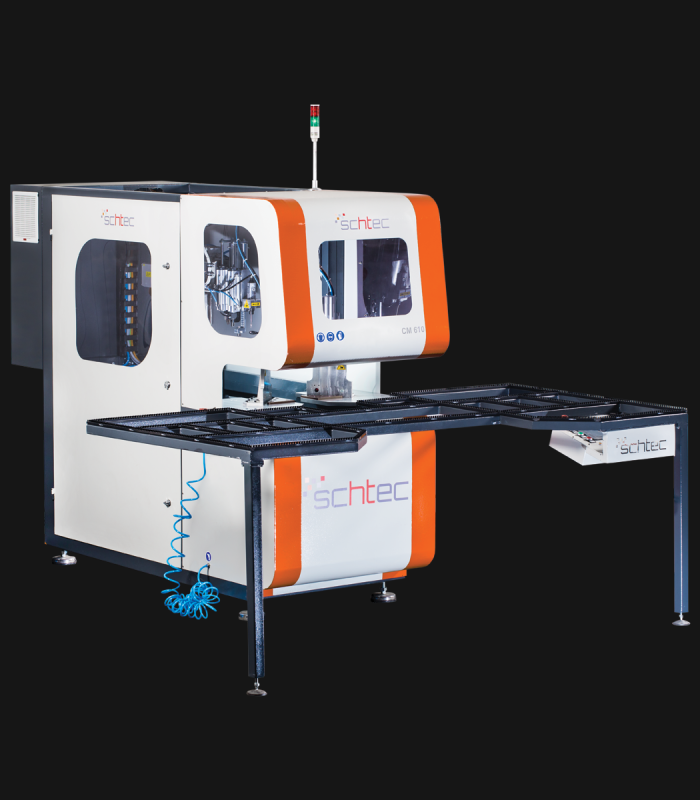

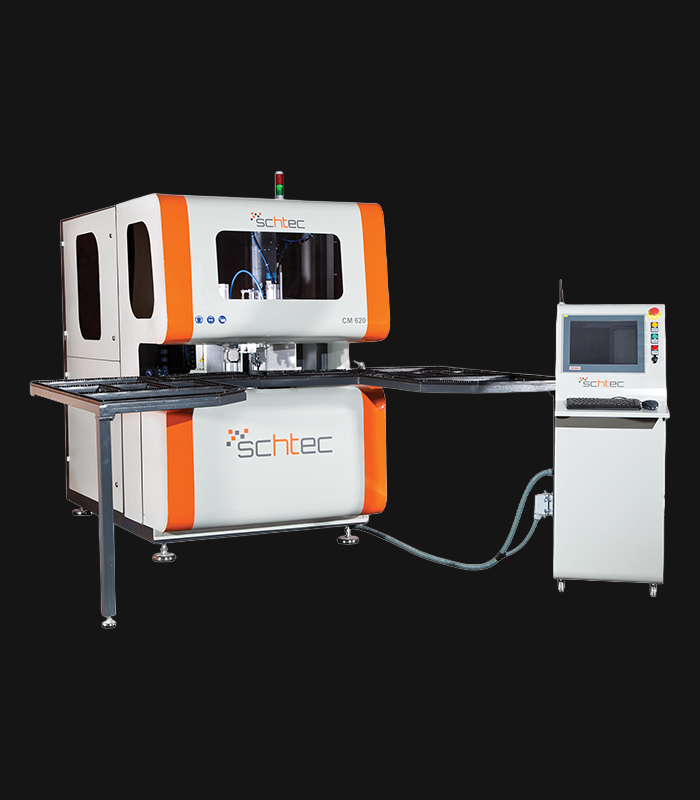

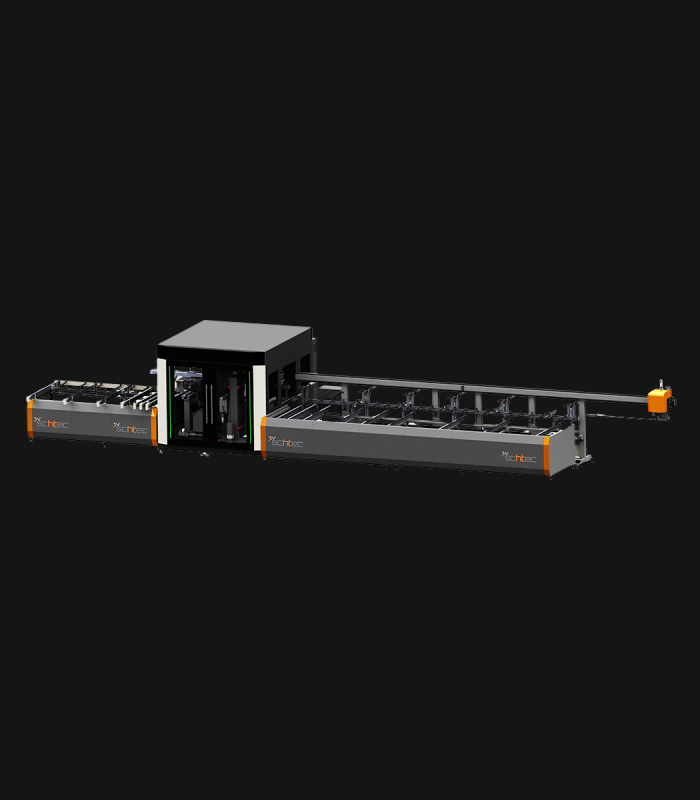

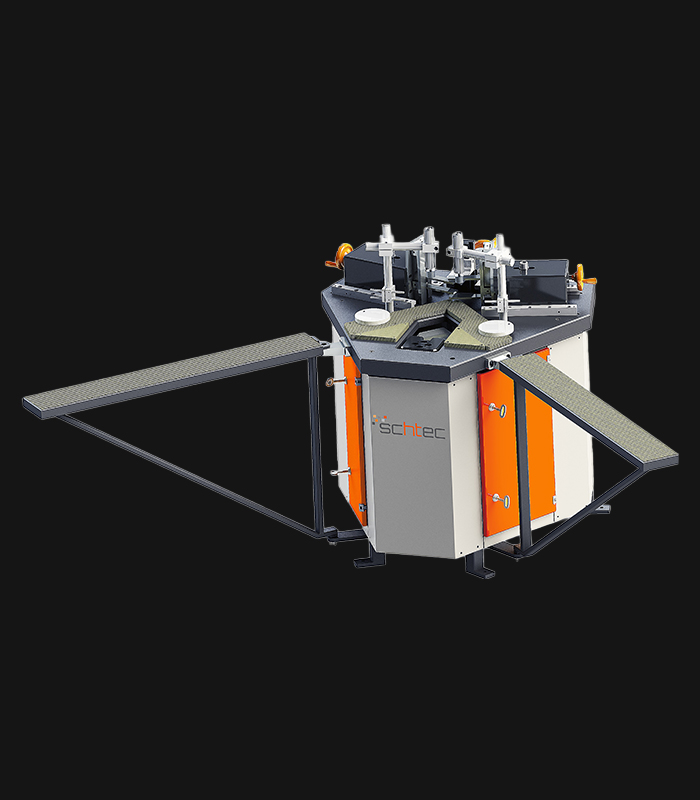

ACR 215 One-Spindle Copy Router Machine

SCHTEC ACR 215: Aluminum profile drilling & milling, -90°/+90° positioning, 1.25 kW motor, 6,000 rpm, compact design for workshops, exported to 65+ countries.

ACR 215 Technical Specifications

| Power Supply | 230 V, 1 Ph, 50-60 Hz |

| Total Power | 1.25 kW, 5.5 A |

| Air Pressure | 6-8 bar |

| Air Consumption | 20 l/min |

| Router Spindle Speed | 6,000 rpm |

| Max. Profile Dimensions | 175 × 135 mm |

| Machine Width | 1,550 mm |

| Machine Height | 2,100 mm |

| Machine Length | 1,750 mm |

| Machine Weight | 400 kg |

Standard Features

- Opens tilt system channel, drain slot, lock cylinders and handle holes on Aluminium profiles

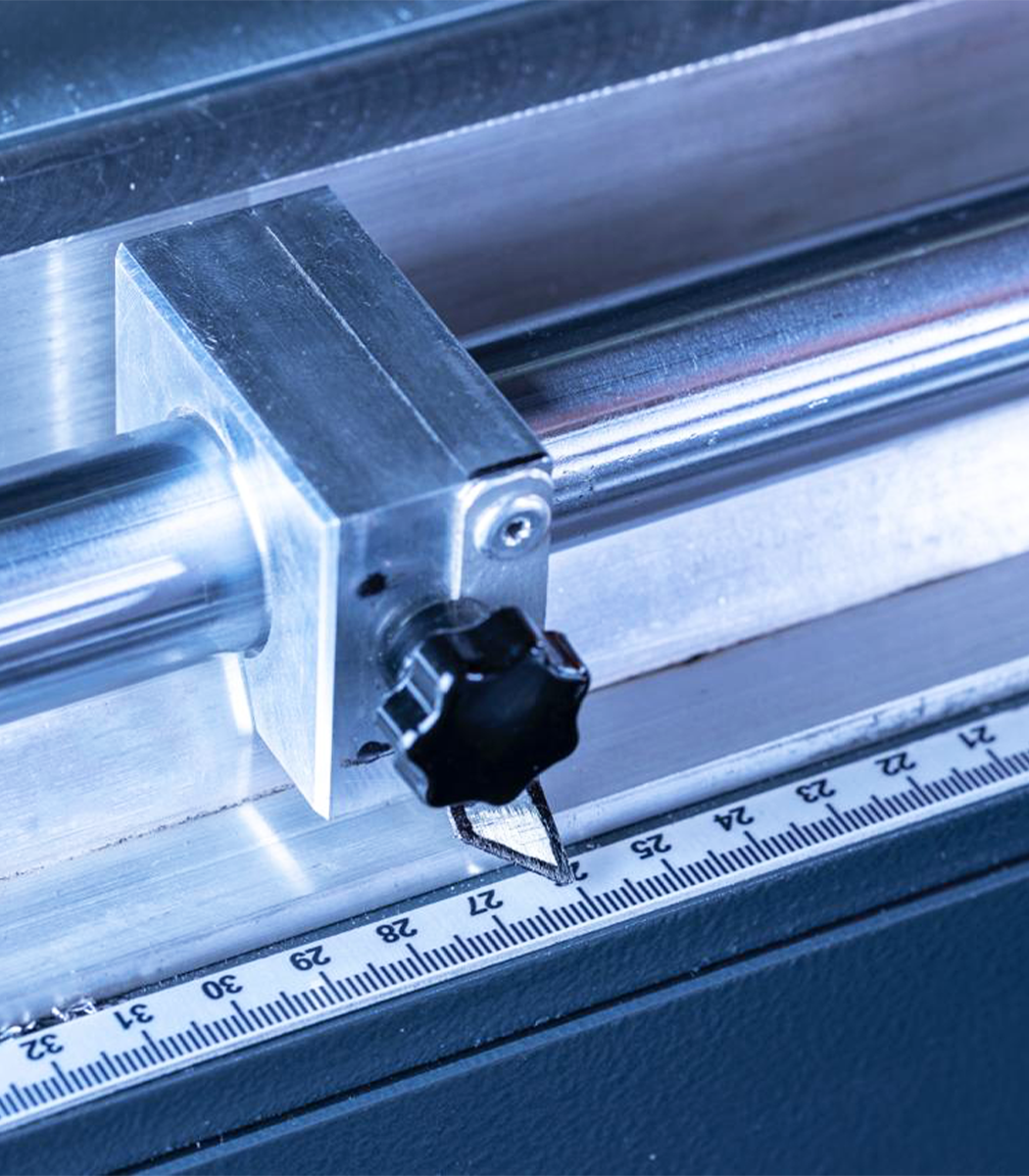

- Working table can be quickly and easily positioned pneumatically at -90°/0°/+90°.

- Pneumatic copying probe comes with three diameters 5/8/10 mm.

- Pneumatic design that easily allows the spindle to stay in the required height position

- Equipped with 4 mobile pneumatic clamps.

- Milling process is done by a frequency controlled high speed motor

- Router spindle speed is changeable via frequency inverter. (from 2800 to 6000 rpm)

- One copy template for standard processing

- 1:1 ratio pattern transfer into a profile from a template

- Manual operation

Optional Features

- Raw template that can be designed as needed

- Cooling system for aluminium profiles

Product Description

The Schtec ACR 215 performs high-precision operations such as espagnolettes, water drainage channels, and other drilling on aluminum profiles. With flexible positioning at -90°/0°/+90° and a frequency-controlled motor running between 2,800–6,000 rpm, it enables 1:1 template processing. Four mobile pneumatic clamps secure the profile, while the 1.25 kW motor ensures energy efficiency. With its compact design, the ACR 215 is ideal for workshops and is exported to over 65 countries under Schtec quality.

Frequently Asked Questions

Find quick answers to common questions about our Copy Router & Drilling Machines for PVC Profiles