Showing the single result

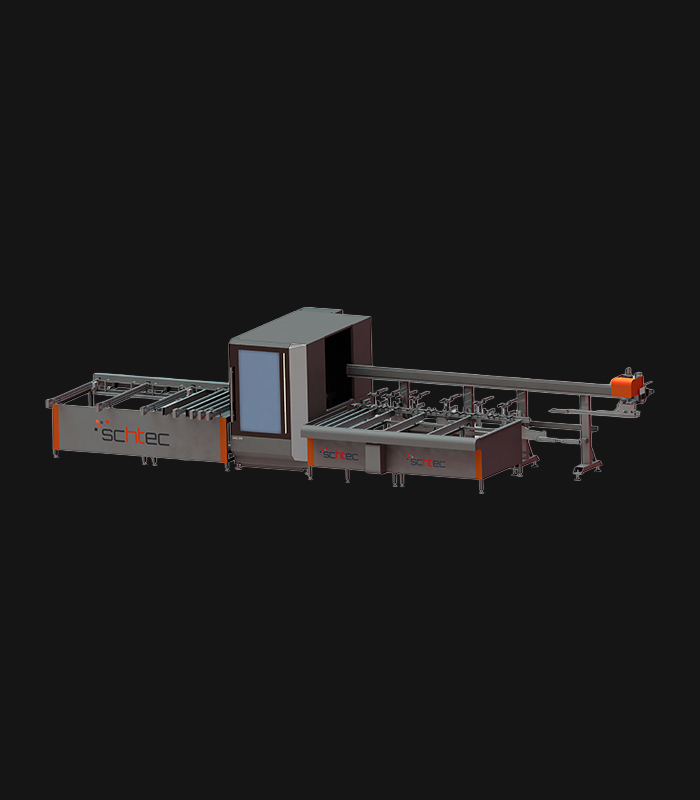

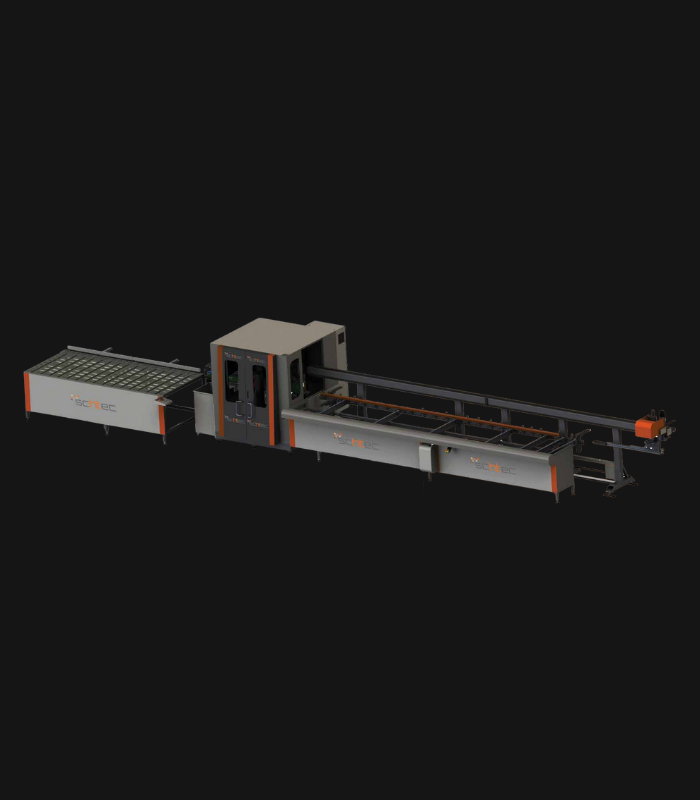

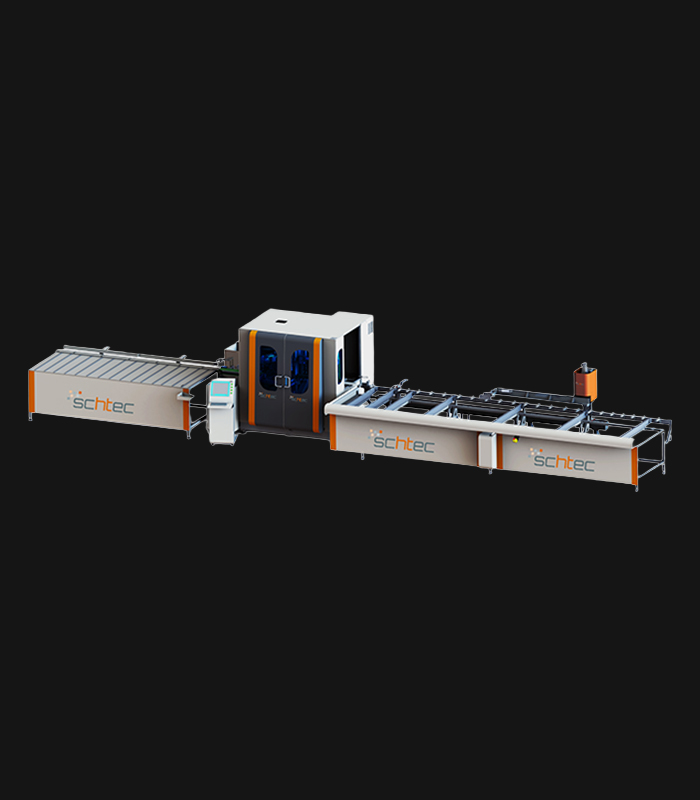

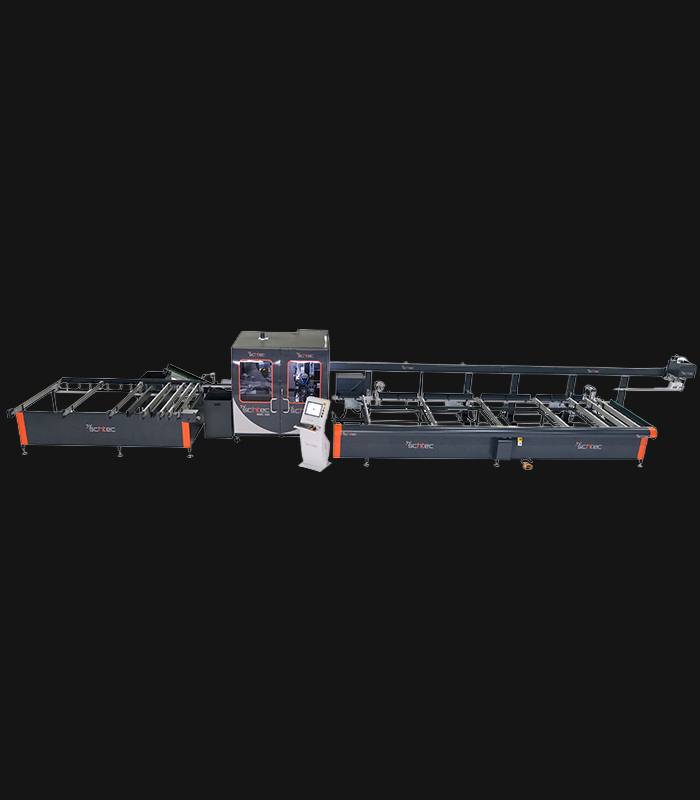

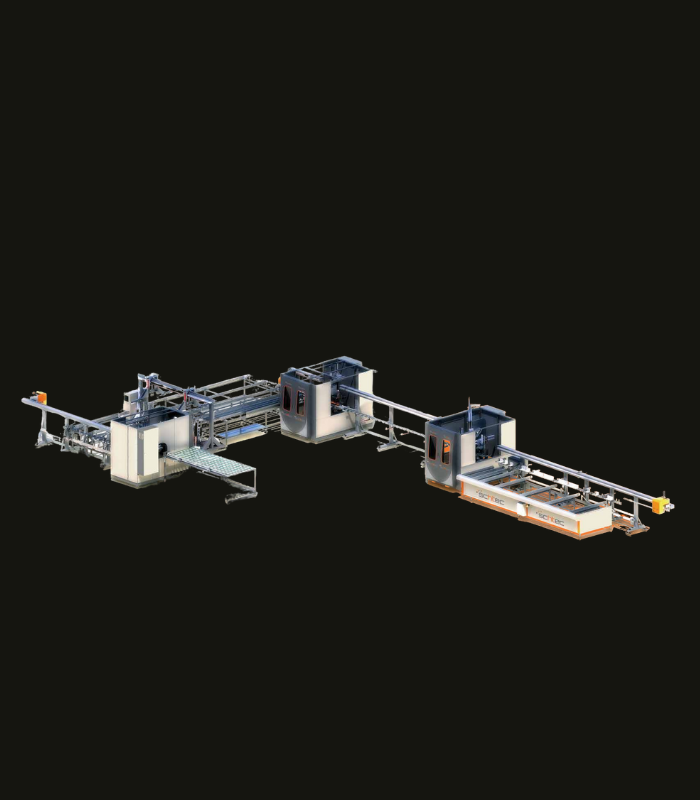

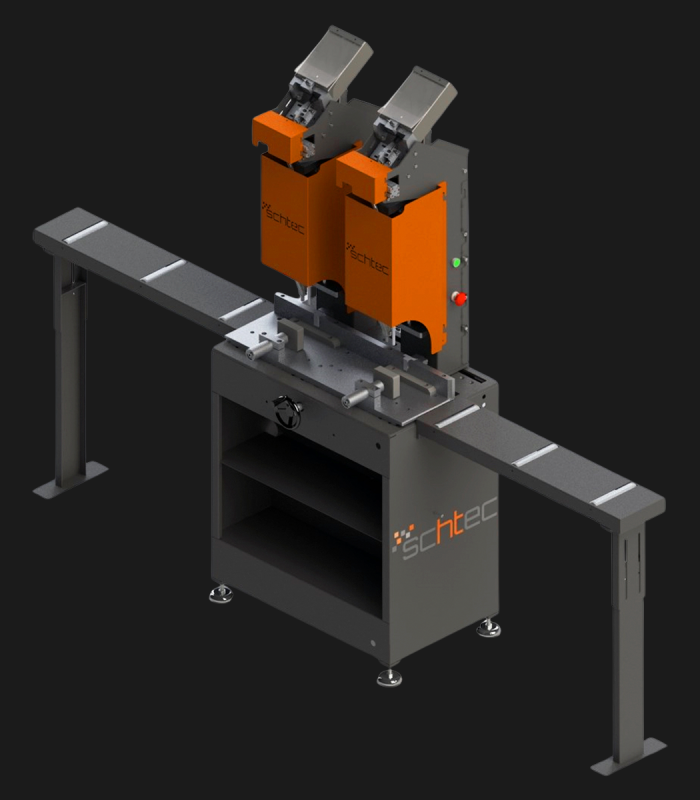

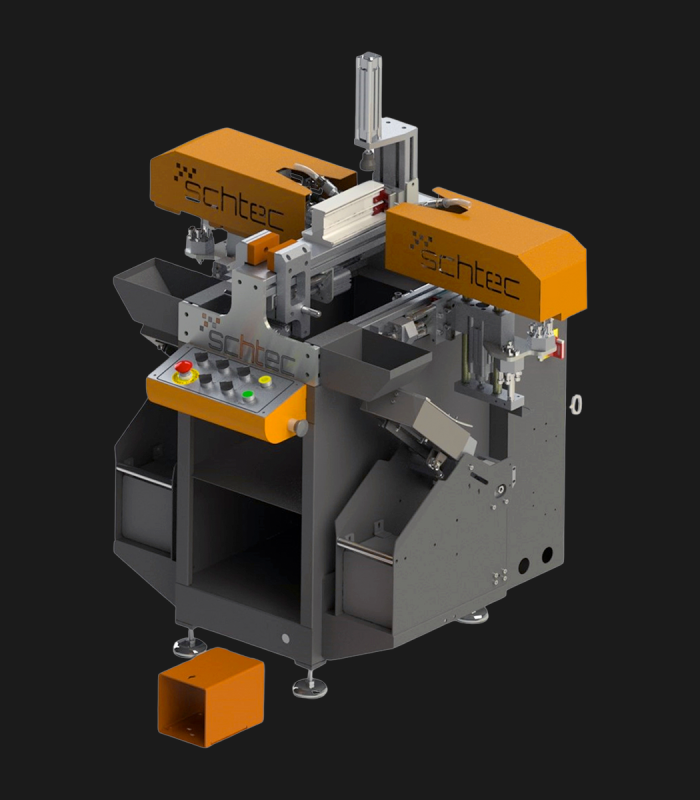

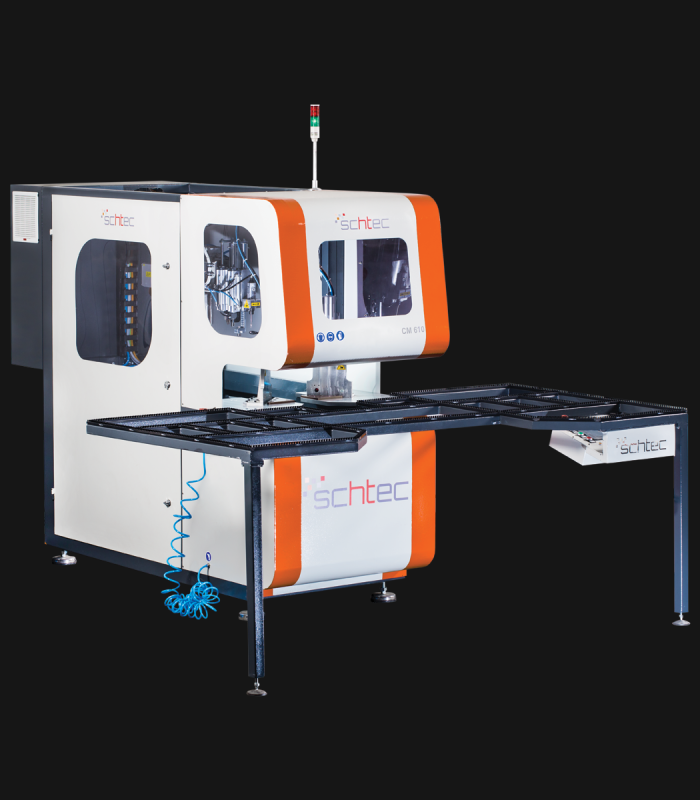

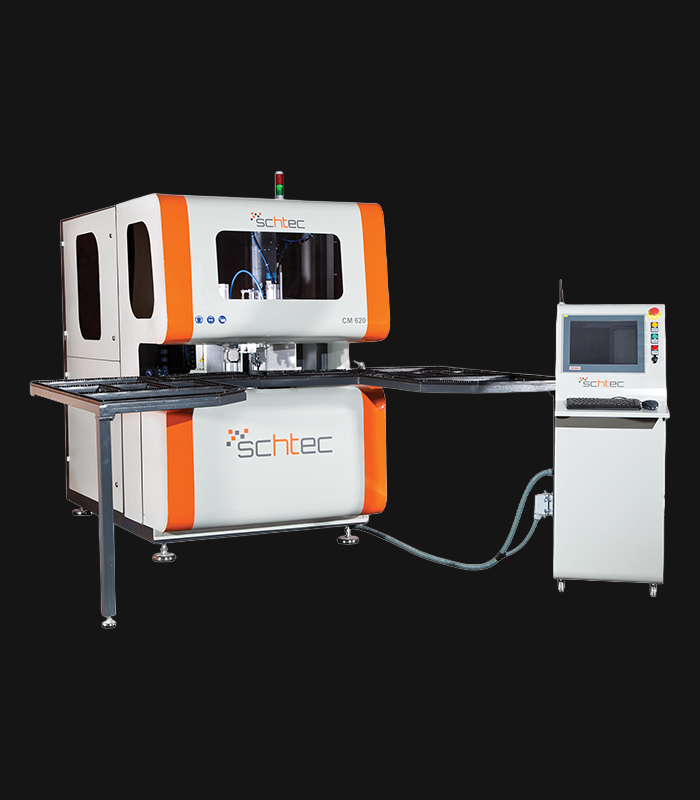

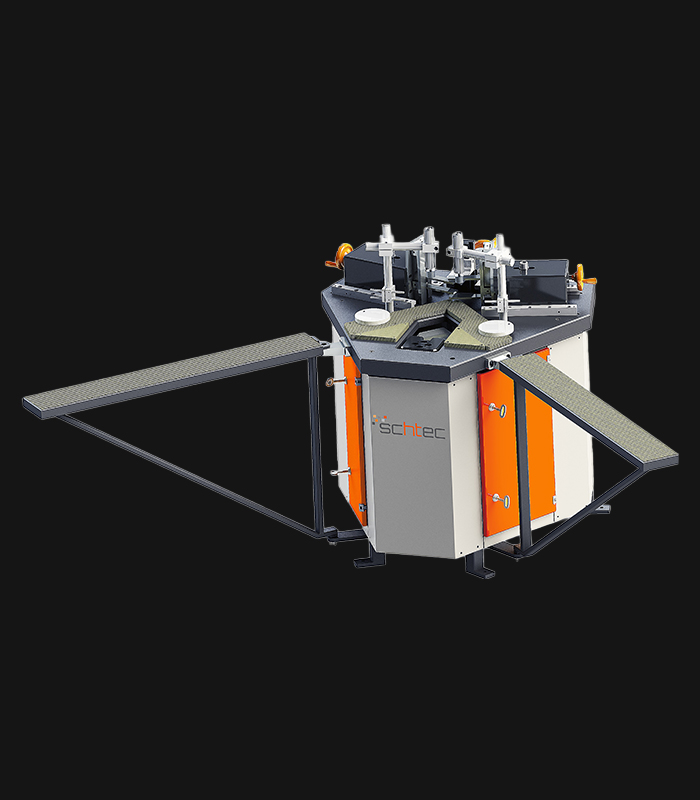

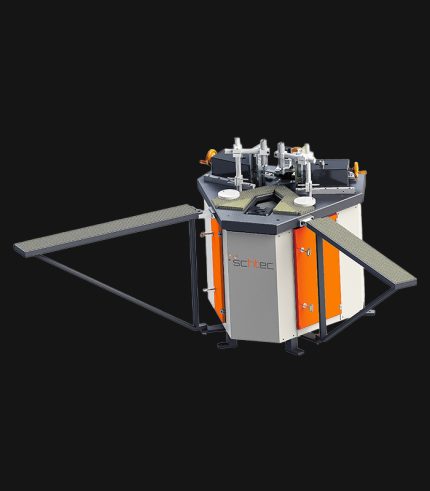

Corner Crimping Machines

Frequently Asked Questions

Find quick answers to common questions about our Corner Crimping Machines.

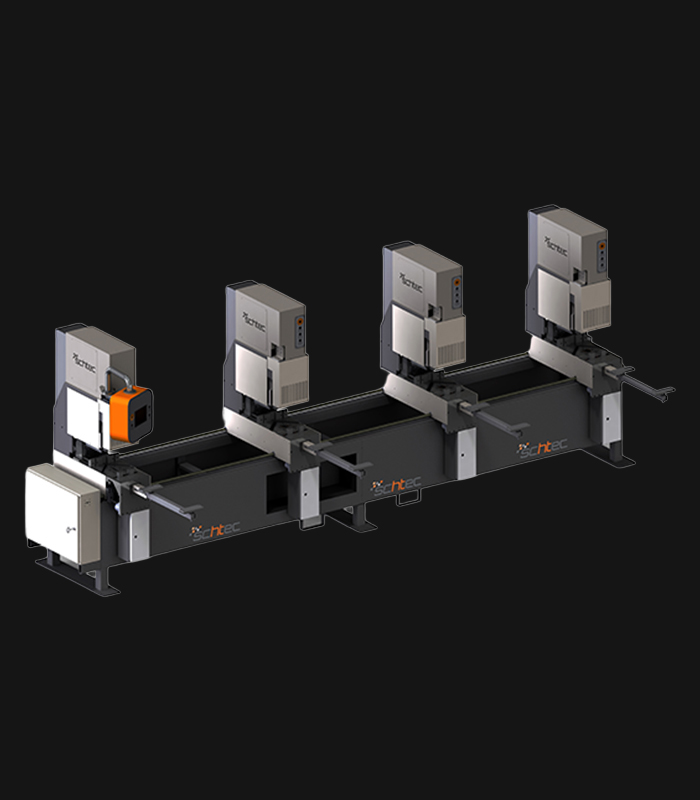

1. What is the main function of an aluminium corner crimping machine?

A corner crimping machine is designed to press and join two aluminium profile ends at a corner angle (often 90°), creating a strong mechanical joint without welding. It applies pressure so that the profiles interlock or deform slightly to form a tight, durable corner connection. This method is often used in aluminium door and window fabrication for consistent, precise frames. By using pressure rather than thermal processes, it preserves the material’s properties and avoids heat distortion.

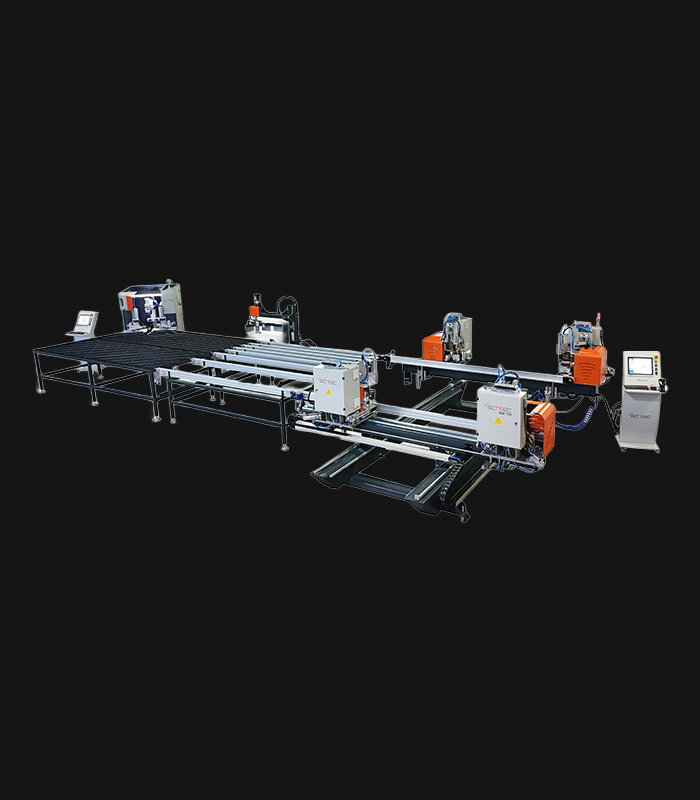

2. What are the key features of the CP 290 Corner Crimping Machine?

The CP 290 Corner Crimping Machine uses a hydropneumatic high‑pressure power system that is relatively easy to maintain, ensuring consistent force during pressing. It can handle different profile sizes and even join small frames thanks to a specially designed clamping unit. The machine includes a quick blade changing system and a front set square system for easier loading and unloading of profiles. The pressing process is controlled step by step via a foot pedal, giving the operator more control and precision.

3. How does the hydropneumatic system benefit corner crimping operations?

The hydropneumatic system combines hydraulic and pneumatic power to deliver strong, stable pressing forces while reducing mechanical complexity. This design ensures smooth and controlled movement of the pressing cylinders, which helps prevent sudden impacts or misalignment. Maintenance tends to be easier because the system has fewer purely hydraulic parts and can leverage pneumatic control elements. The result is more consistent corner crimping quality with less wear on components over time.

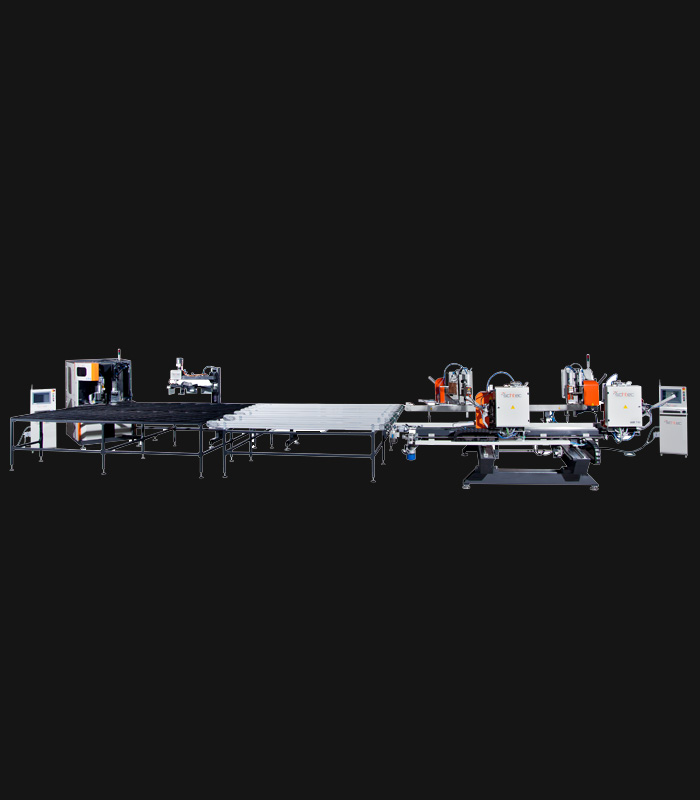

4. How flexible is CP 290 in terms of profile size and applicability?

CP 290 supports a wide range of profile dimensions, which gives fabricators the flexibility to work on many aluminium systems. It also includes special clamps to handle smaller frame sizes that might otherwise be difficult to crimp. The front square system is engineered for easier insertion and removal of profiles during production. Thanks to these features, the machine can adapt to changing product lines or different profile series without extensive retooling.

5. What maintenance practices help achieve long life and consistent performance with CP 290?

Regular cleaning of the pressing area, removal of chips or debris, and lubrication of moving surfaces are essential to maintain precision and prevent wear. Check the pressing cylinders, seals, and air supply lines periodically for leaks or damage. The quick blade change mechanism should be inspected and kept free of buildup so that tool changes remain fast and safe. Calibration and verification of alignment should be done routinely to ensure that corners remain square and accurate. By adhering to these practices, you can reduce downtime and extend the machine’s lifespan.