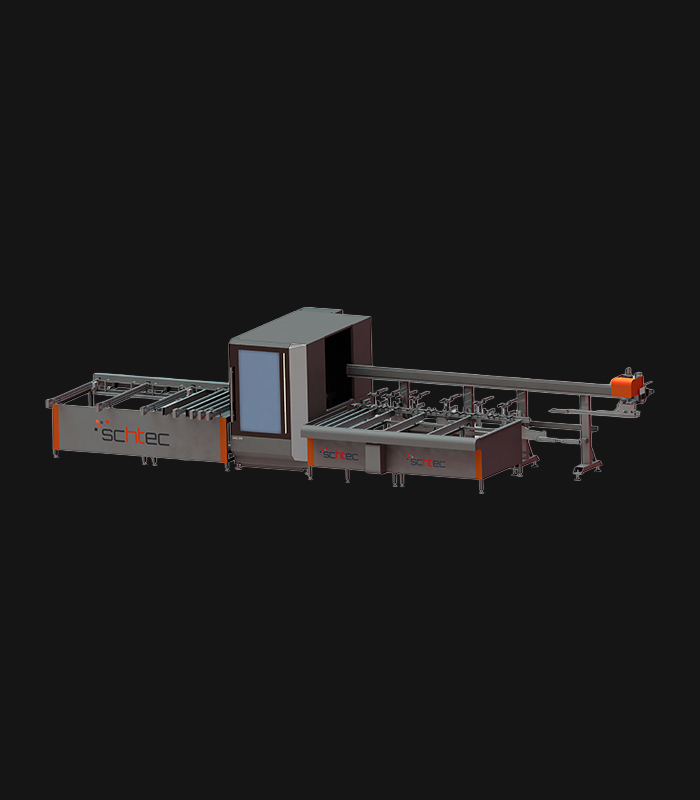

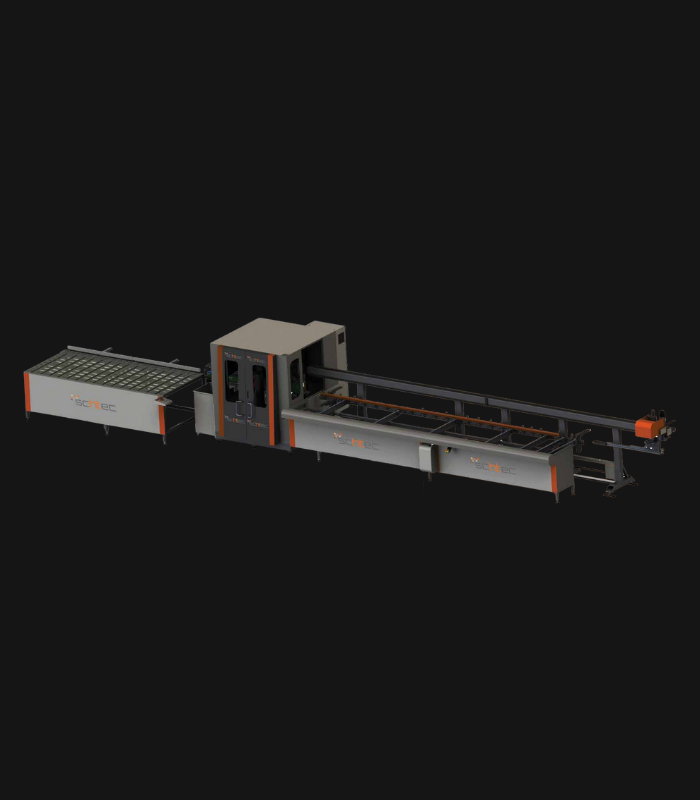

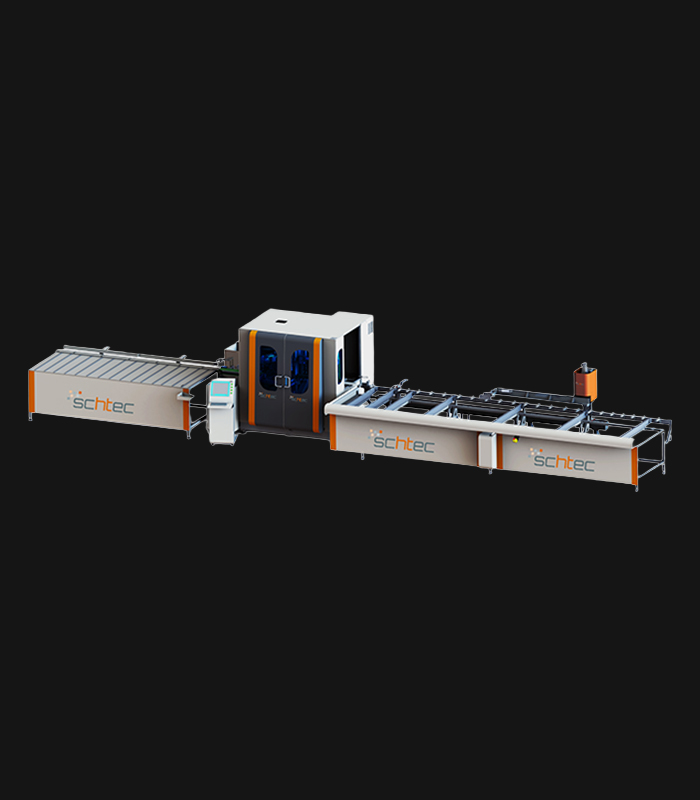

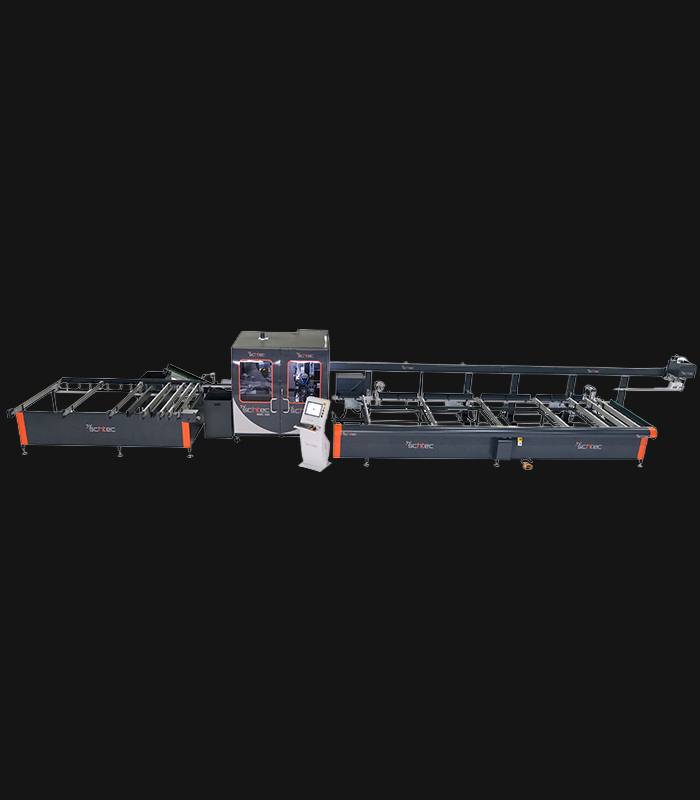

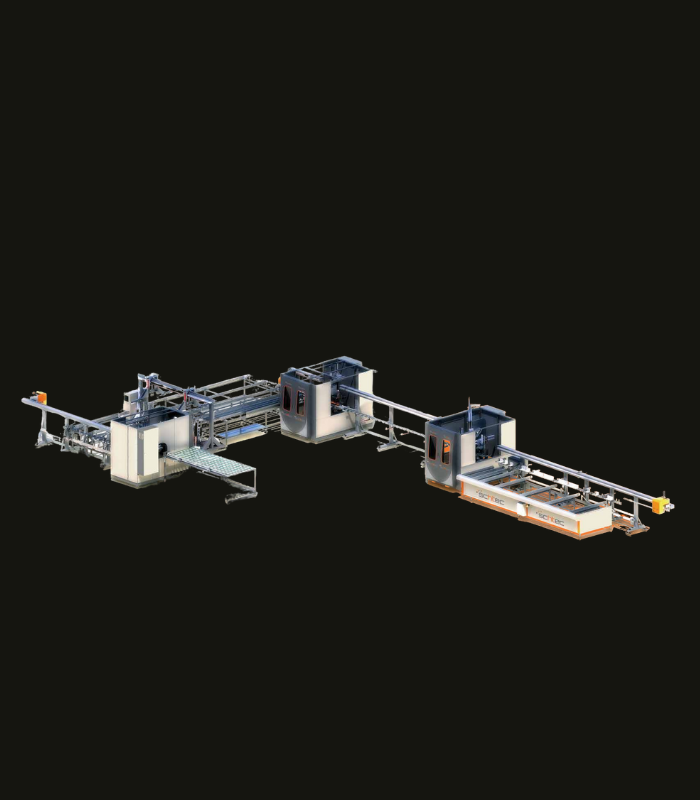

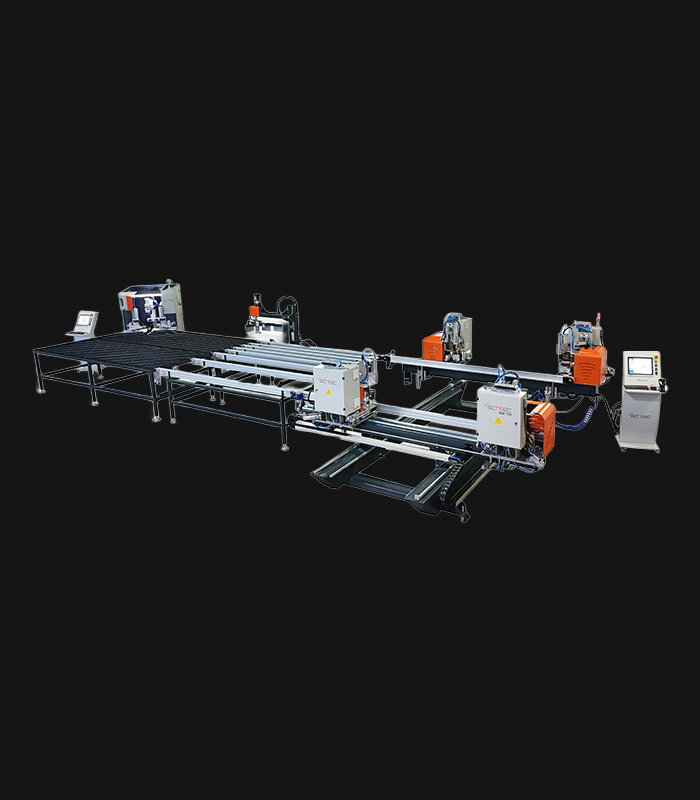

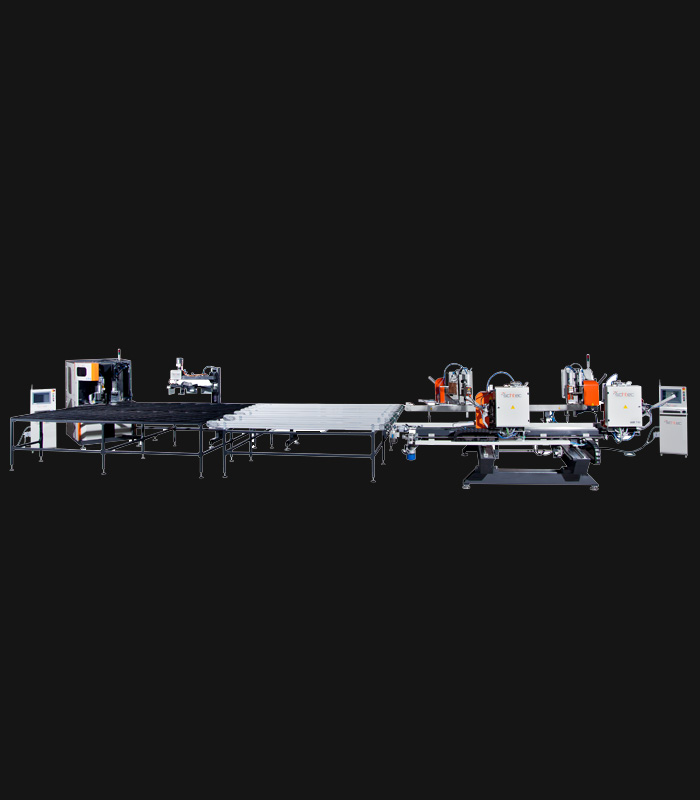

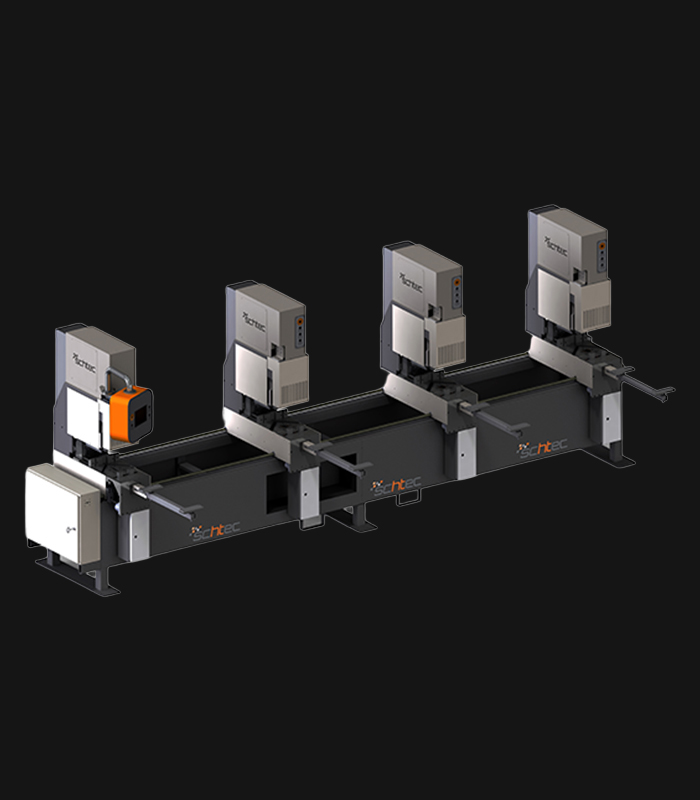

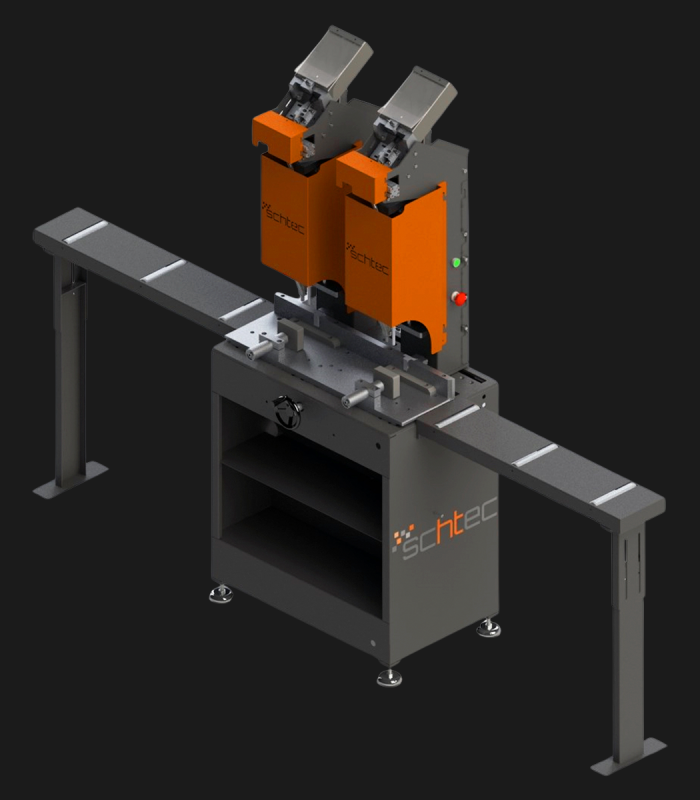

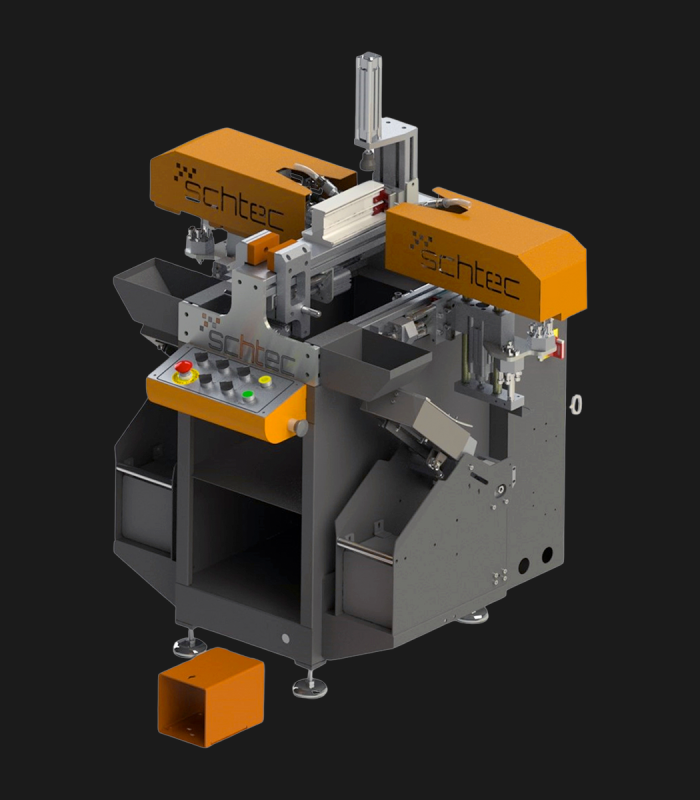

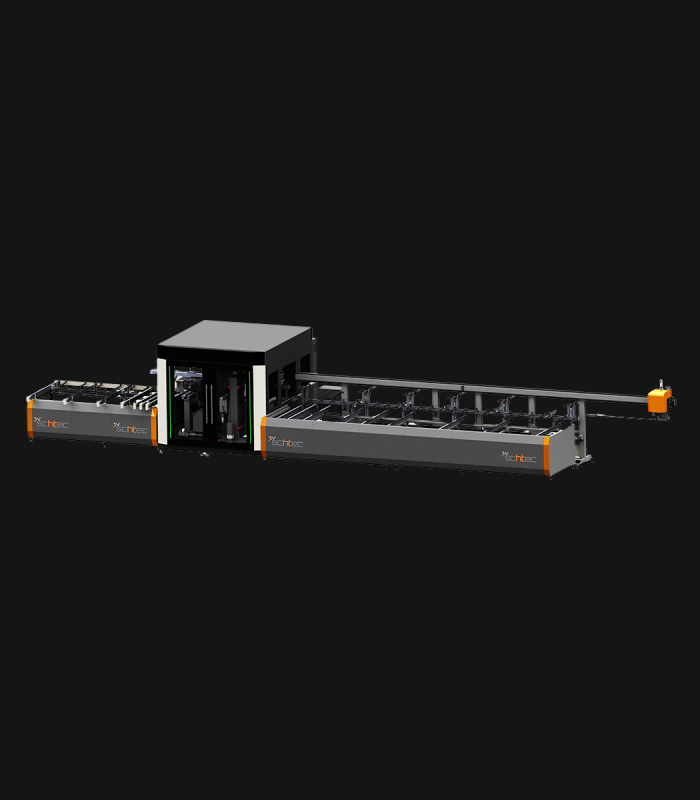

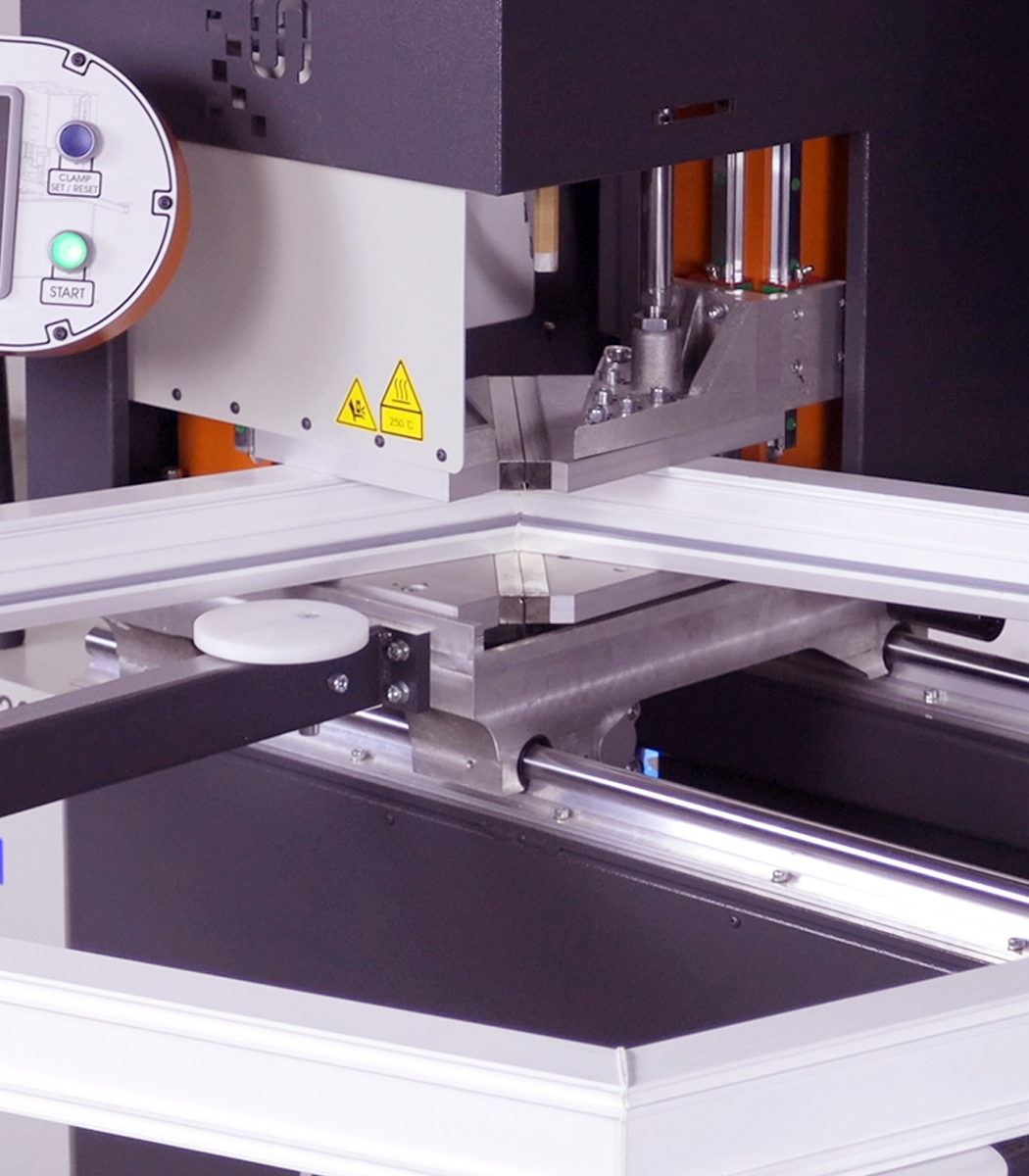

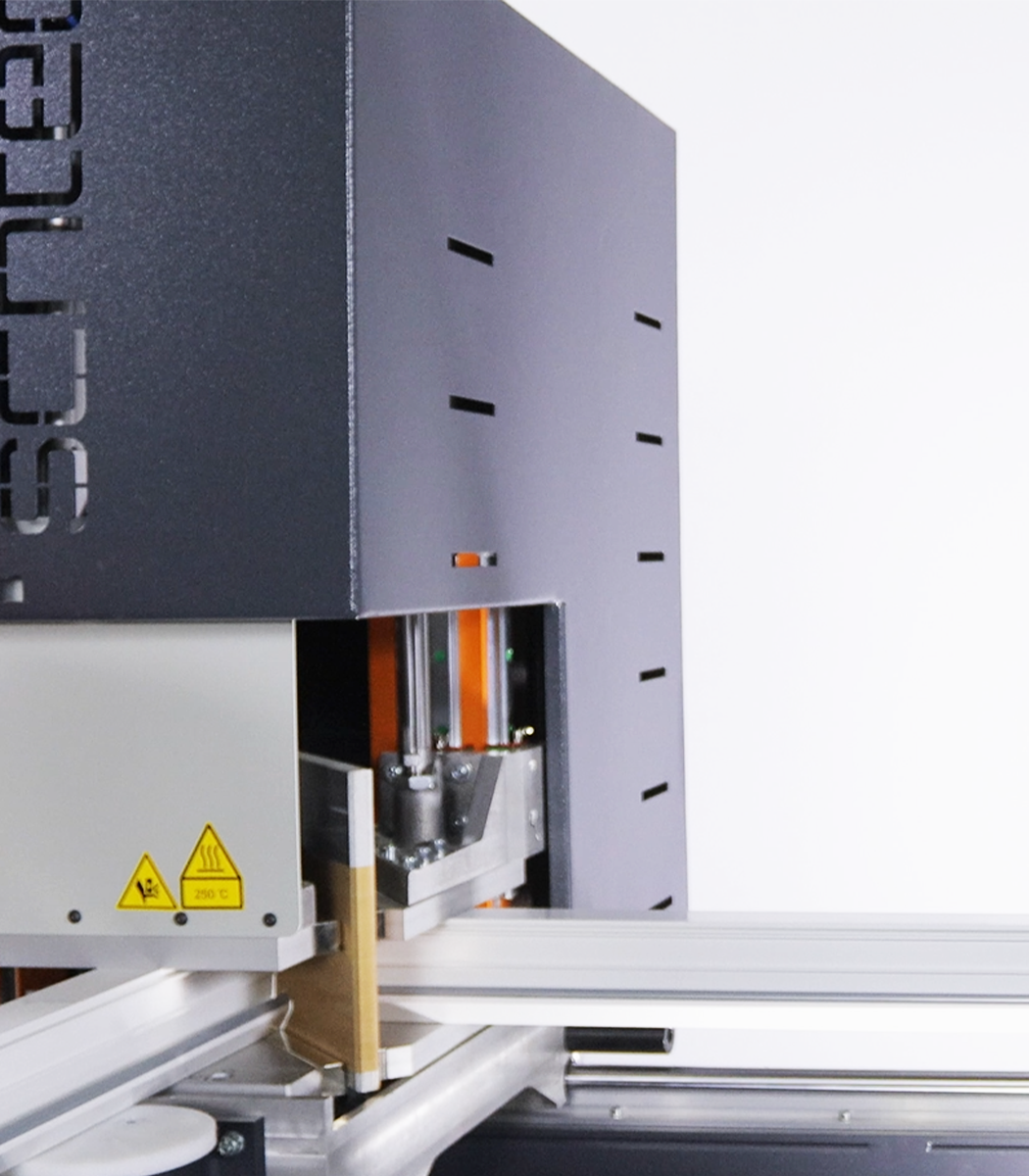

WD 720 Double Head Welding Machine

Schtec WD 720 welds two PVC corners at 60°-180° with 0.2mm precision. Touch screen controls, durable Teflon, and pneumatic brake for efficient welds.

WD 720 Technical Specifications

| Power Supply | 220 V, 1 ph, 50-60 Hz |

| Power Output | 4,2 kW |

| Max. Welding Length | 3.460 mm |

| Min. Welding Length | 385 mm |

| Max. Profile Width | 150 mm |

| Max. Profile Height | 210 mm |

| Min. Profile Height | 38 mm |

| Air Pressure | 6-8 bar |

| Air Consumption | 100 lt/min. |

| Machine Height | 1.900 mm |

| Machine Length | 4.540 mm |

| Machine Width | 1.570 mm |

| Machine Weight | 900 kg |

SKU:

WD-720

Category: Welding Machines

Description

Standard Features

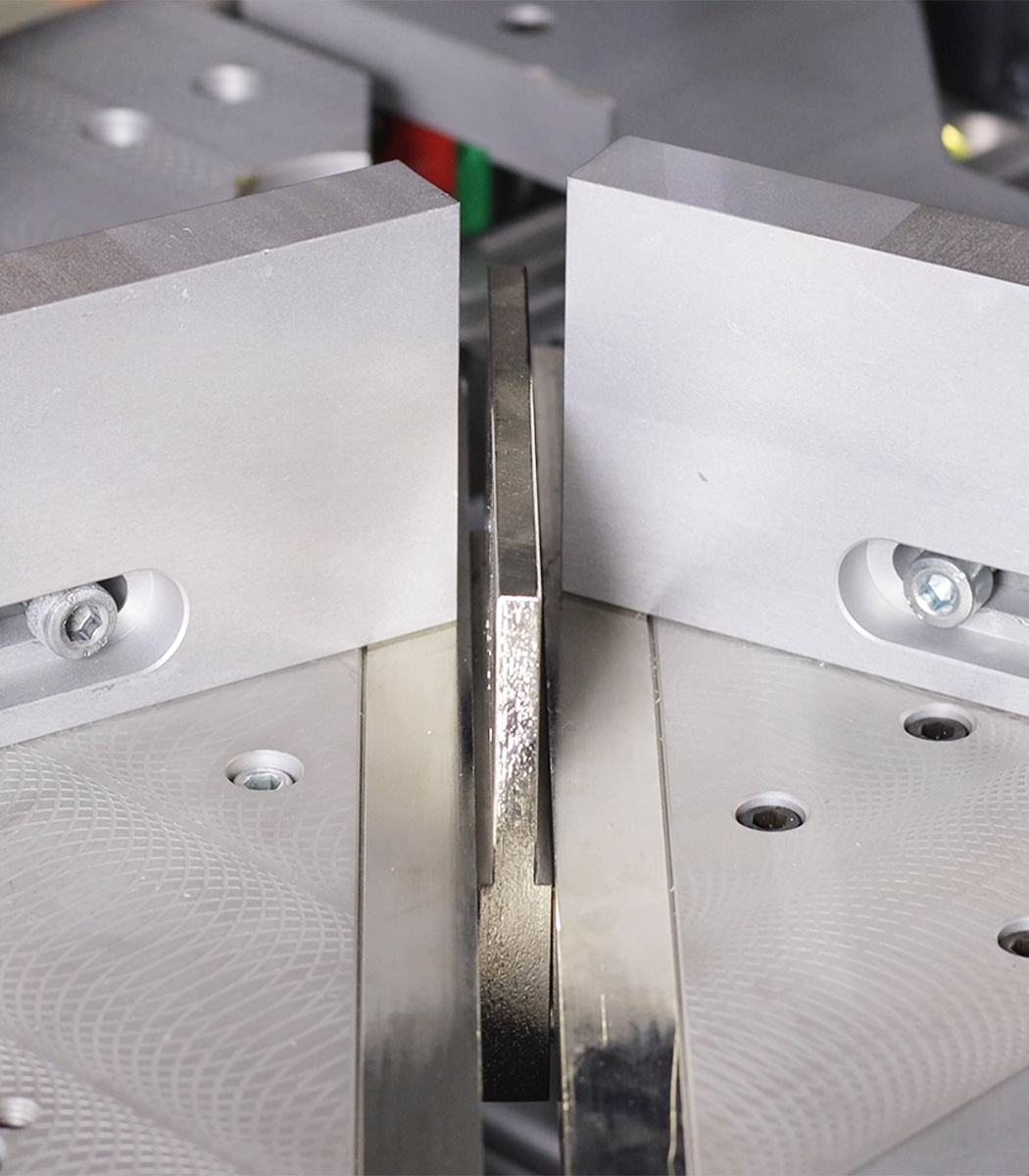

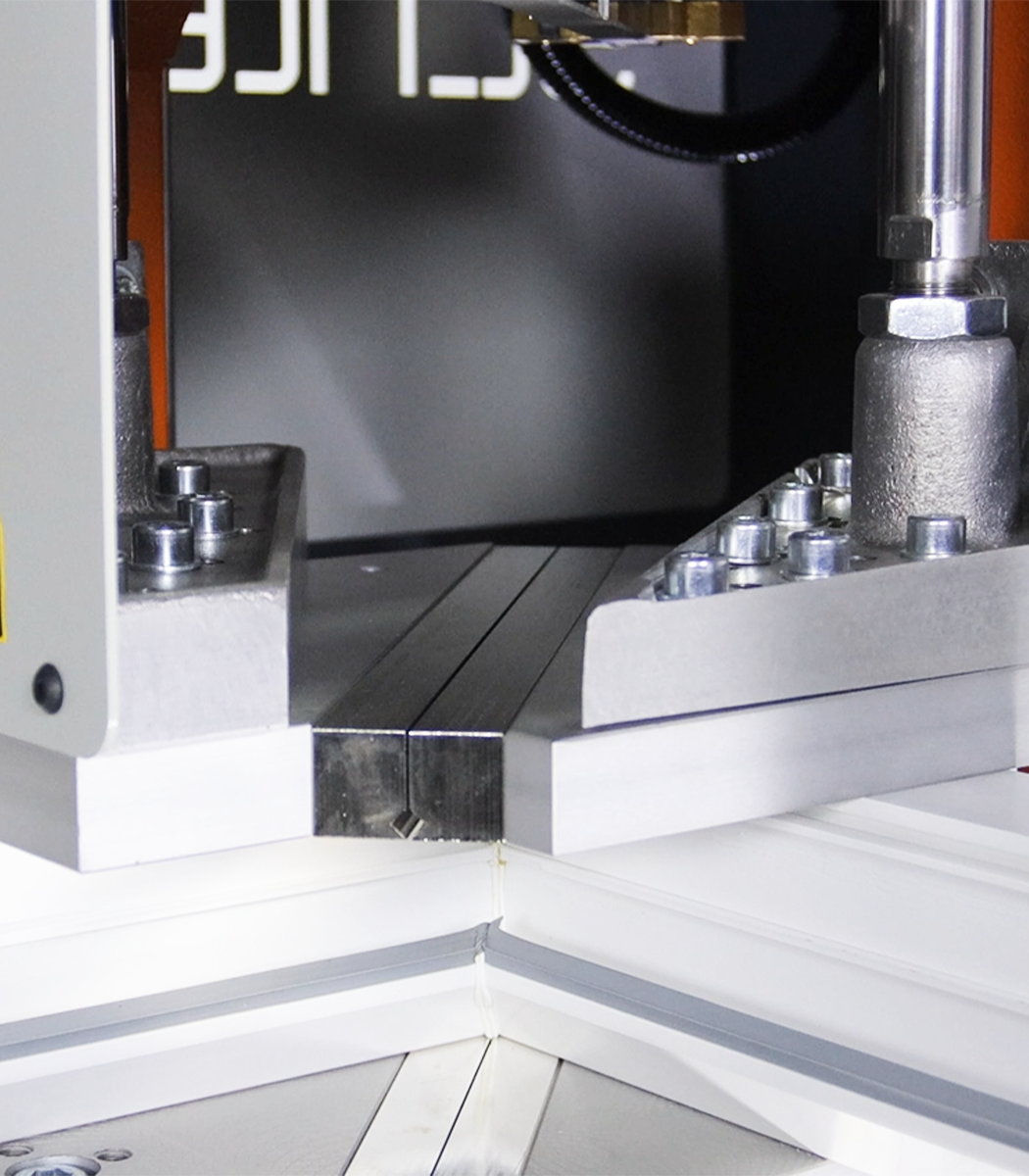

- High precision welding of two corners of PVC profiles in a single operation

- Precision welding at variable angles between 60° – 180°

- Capable of single head welding operation when needed

- 0,2 mm welding seam restriction for both coloured and white profiles

- Manual positioning of the movable head and pneumatic brakes

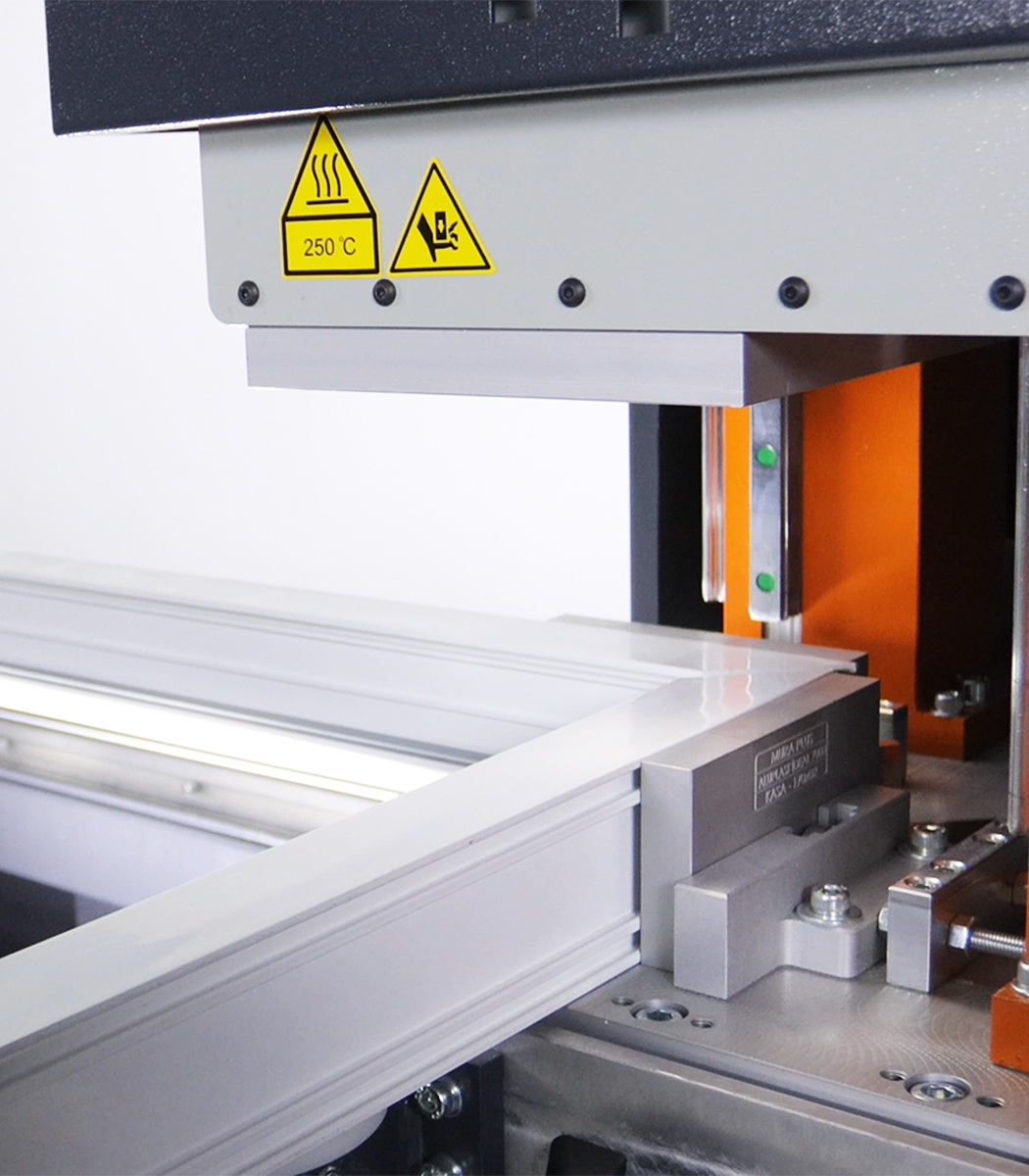

- Heating, temperature and time parameters can be adjusted individually

- Digital touch screen display to control all operations

- Homogenous heating with special heating plates

- Easy heater plates cleaning system during maintenance

- More efficient and long lasting Teflon due to special Teflon system on the heating plates

- Specially designed mould system to save time

Product Description

The Schtec WD 720 precisely welds two corners of PVC profiles simultaneously at angles between 60° and 180°. With a 0.2 mm welding tolerance, it ensures strong and aesthetic joints. A touchscreen panel allows adjustments for heat, time, and angle. The manually positioned moving head and pneumatic brake system make it easy to operate. It features a long-lasting Teflon system and uniform heat distribution, offering both single and double-head welding options—ideal for mid-sized production lines.

FAQ

Welding Machines

Frequently Asked Questions

Find quick answers to common questions about our Welding Machines.

1. What is the main purpose of a welding machine in PVC manufacturing?

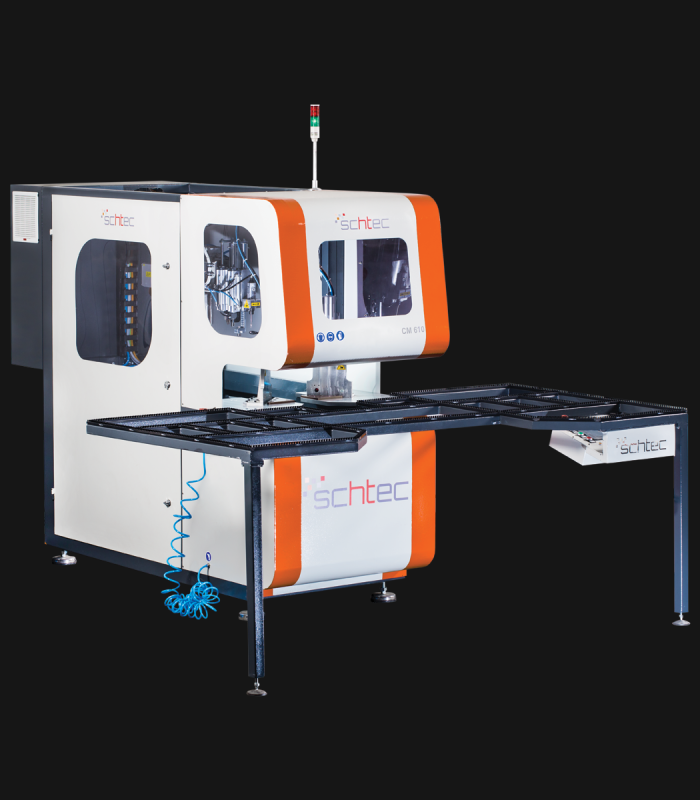

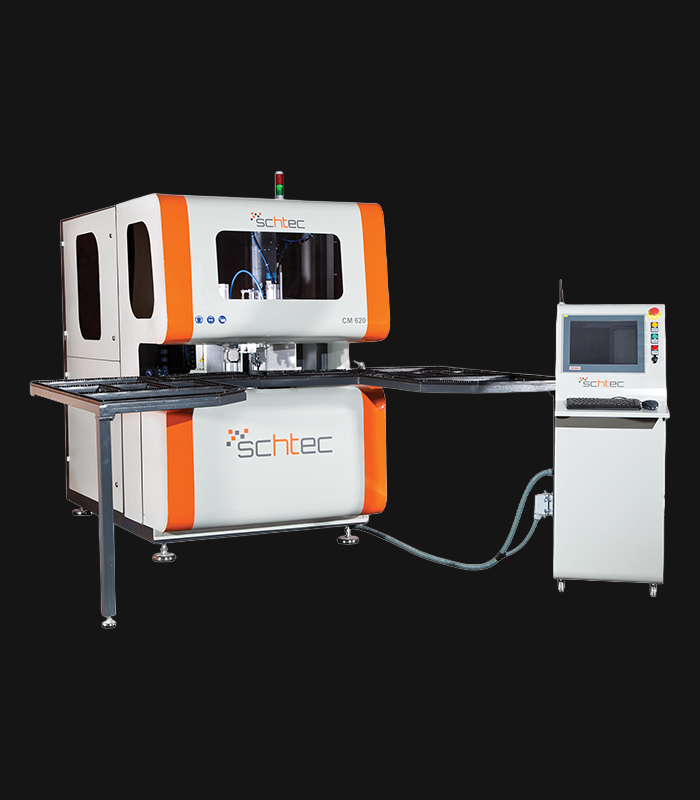

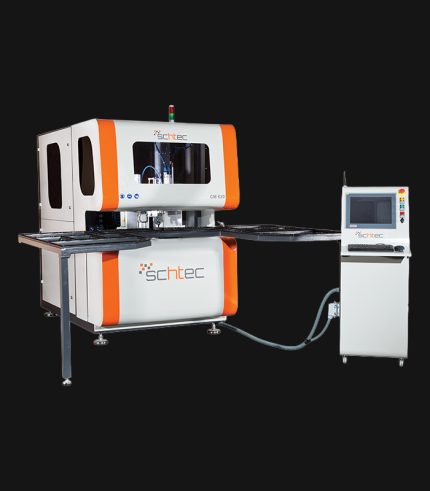

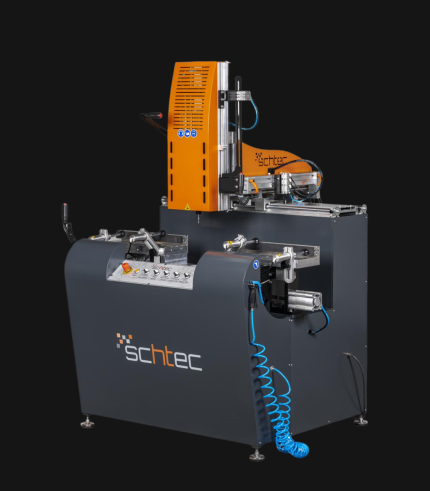

Welding machines like WM 750 Four Head Welding Machine and WD 710 Single Head Welding Machine are used to fuse PVC profile corners by melting material, creating seamless and durable frames. They eliminate the need for mechanical fasteners and ensure air‑ and water‑tight joints. Consistent heat control and pressure maintain structural integrity and appearance over many cycles. In automated lines, welding machines coordinate with cleaning and cutting stations for full process flow.

2. What features should you expect in a high‑performance PVC welding machine?

High‑performance welding machines typically feature servo‑driven axes, parallel welding systems for balanced pressure, PID temperature controllers, and mold parameter storage for multiple profile types. Rapid mold changeover, central lubrication, and Teflon handling systems reduce maintenance downtime. Safety enclosures, light barriers, and efficient air management are also essential. Robust user interfaces and remote diagnostics enhance usability and monitoring.

3. How does the WM 750 Four Head Welding Machine boost productivity?

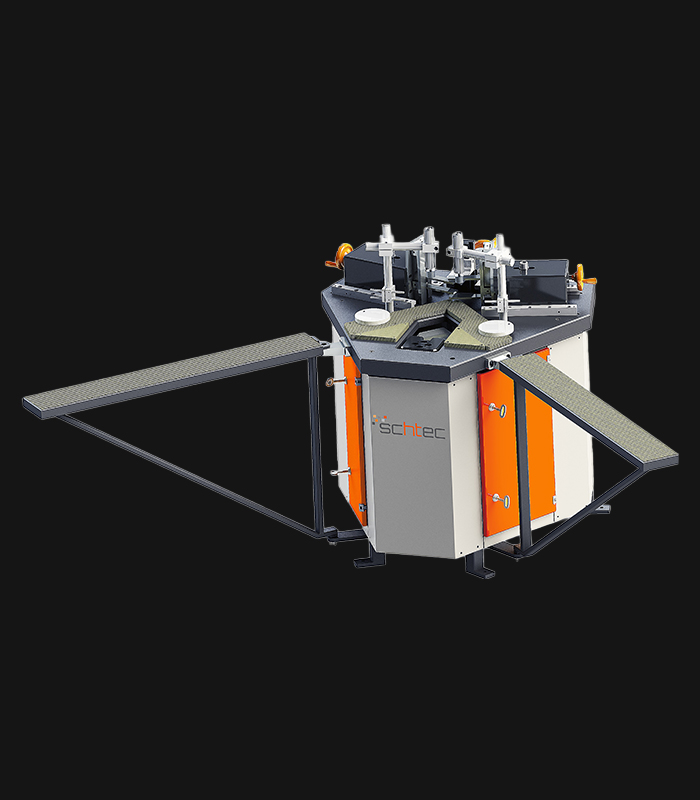

The WDV 724 is ideal for continuous inline production environments where profiles move through the machine, welding in a flow setup. The WD 720 Double Head Welding Machine is suitable when moderate capacity and flexibility are needed, allowing two corners to be welded simultaneously. Single head machines like WD 710 are good for smaller runs or limited footprint setups. Four‑head machines like WM 740 are preferred for highest throughput in batch production.

4. When would you choose WDV 724 Four Head Inline Welding Machine or WD 720 Double Head Welding Machine?

The WDV 724 is ideal for continuous inline production environments where profiles move through the machine, welding in a flow setup. The WD 720 Double Head Welding Machine is suitable when moderate capacity and flexibility are needed, allowing two corners to be welded simultaneously. Single head machines like WD 710 are good for smaller runs or limited footprint setups. Four‑head machines like WM 740 are preferred for highest throughput in batch production.

5. What maintenance practices ensure durable performance in welding machines?

Clean welding platens, remove residue, and inspect Teflon surfaces regularly to prevent imperfections. Calibrate temperature sensors, PID controls, and servo axes periodically to preserve accuracy. Check pneumatic lines, seals, and air pressure to maintain consistent force during welding. Lubricate motion components and adhere to central lubrication schedules. Monitor error logs, evaluate weld quality, and schedule preventive services to avoid unplanned downtime.